System and method for controlling guy jacquard

A technology of a control system and a control method, applied in the field of textile machinery, can solve the problems of slow running speed and cumbersome operation, and achieve the effects of improving efficiency, simple operation and avoiding failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

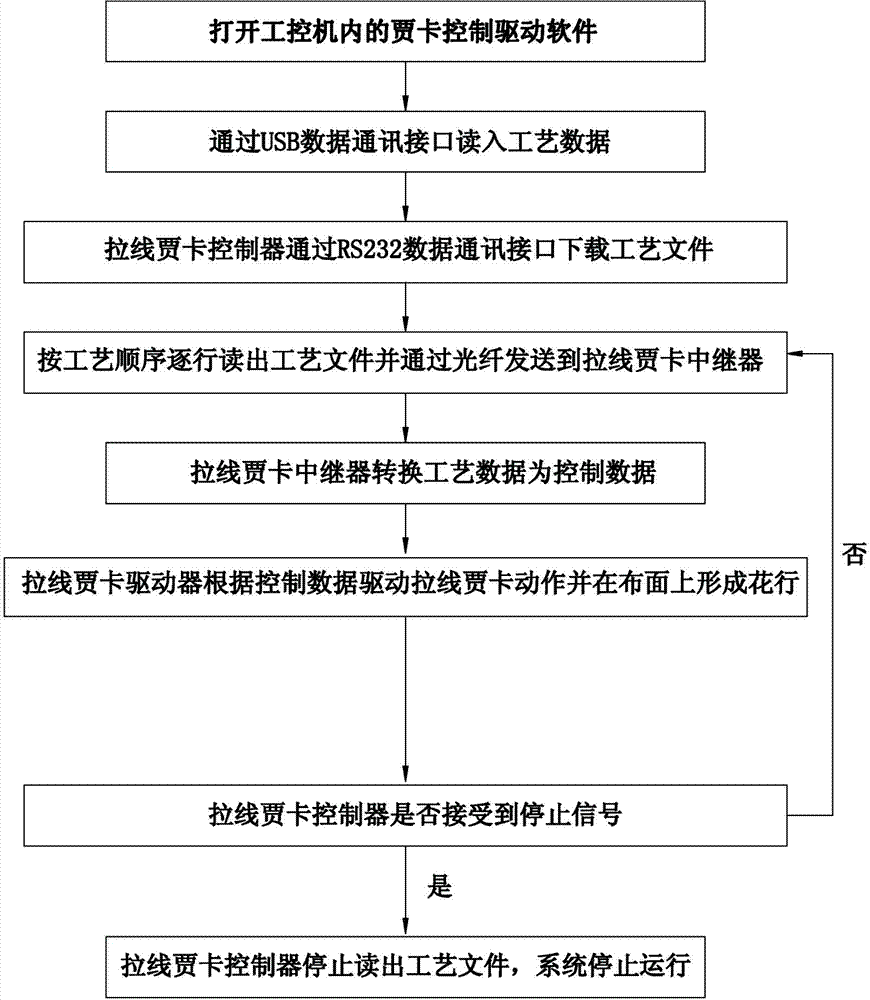

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

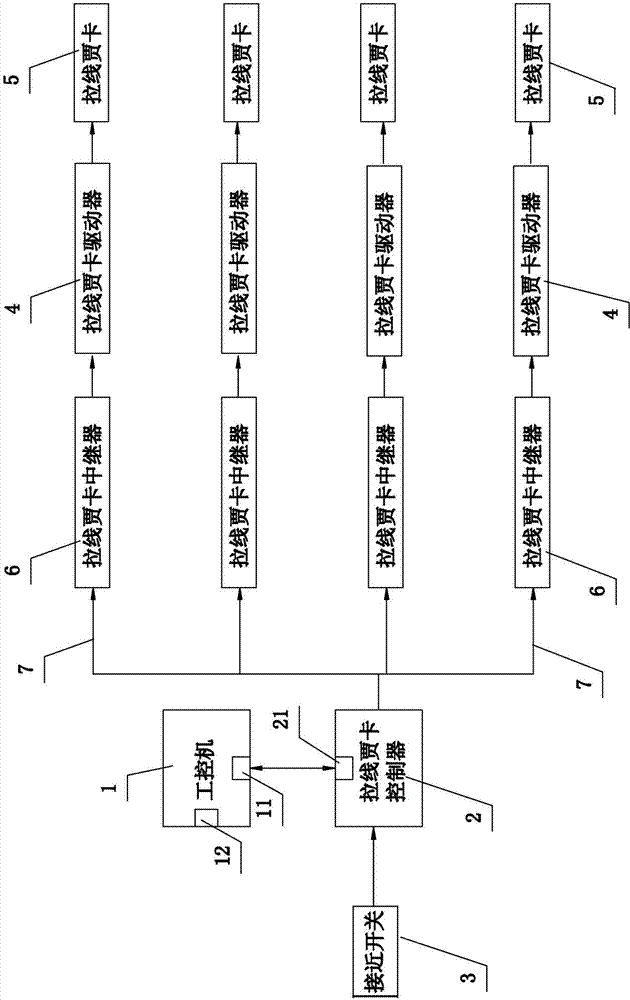

[0031] refer to figure 1 . A control system for a pull-wire jacquard, comprising an industrial computer 1 , a pull-wire jacquard controller 2 , a pull-wire jacquard repeater 6 , a proximity switch 3 , a pull-wire jacquard driver 4 and a pull-wire jacquard 5 . The industrial computer 1 is an ordinary industrial control computer with corresponding cable jacquard driver software built in, and the industrial computer 1 is provided with a data communication interface 11 capable of data communication with the cable jacquard controller 2 and A data communication interface 12 for reading Jacquard process documents, wherein the data communication interface 11 is an RS232 data communication interface, and the data communication interface 12 is a USB data communication interface. The proximity switch 3 is used to determine the position information of the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com