x-ray conversion target

A technology for converting targets and X-rays, applied in X-ray tube electrodes, X-ray tube components, etc., can solve the problems of interference, thermal stress and thermal deformation, large heat generation of the substrate, and low conversion efficiency, so as to improve the service life , Achieve temperature uniformity and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

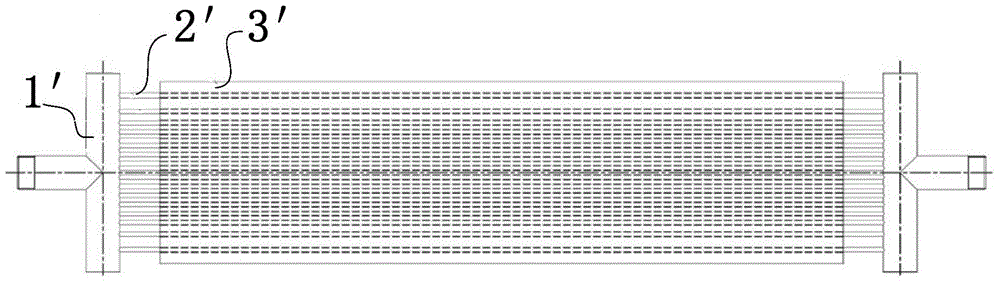

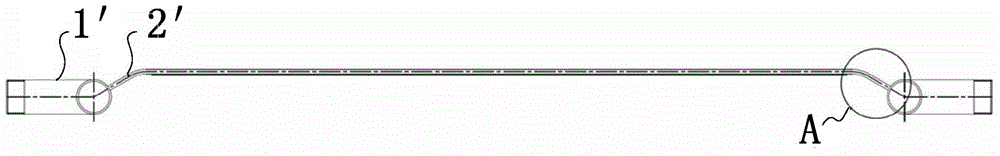

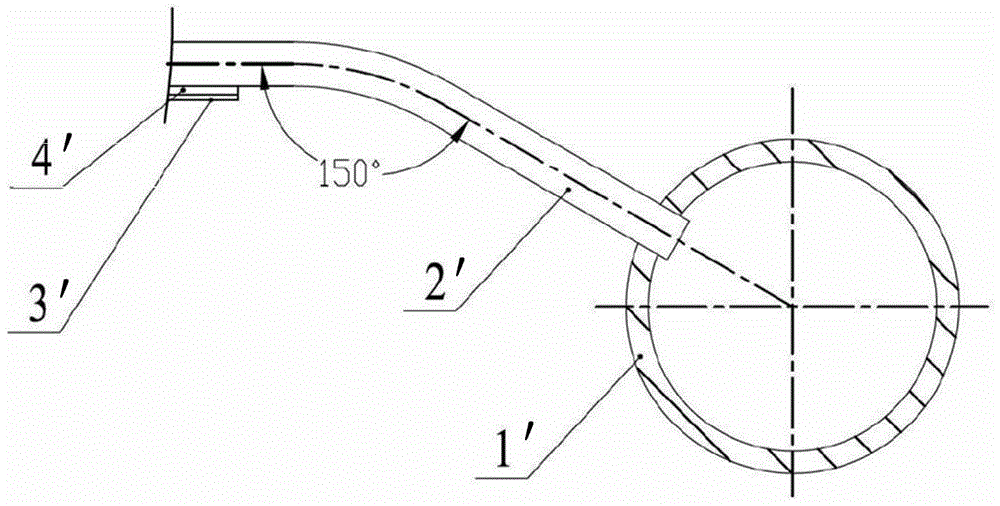

[0070] Such as Figure 4~5 As shown, the X-ray conversion target of the present invention includes a base body 1 and a target layer plate 3 . The base body 1 includes a base plate 12 and a frame 13 . The frame 13 is fixed on the peripheral wall of the base plate 12 . The target layer board 3 is detachably connected with the frame 13 . In this embodiment, the target laminate 3 and the frame 13 are connected by screws, which facilitates disassembly and fixing of the conversion target.

[0071] Wherein, the target layer plate 3 is sealed and connected with the frame 13 through a sealing ring 8, which can ensure the sealing of the conversion target and prevent the coolant passing into the coolant layer from overflowing from the side of the base body 1. Meanwhile, the X-ray conversion target also includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com