Wire stripper

A technology of wire strippers and wires, which is applied in the direction of instruments, parts of electrical measuring instruments, cable installation devices, etc., and can solve problems such as inappropriate detection methods and difficulties in ensuring points connected to corresponding mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

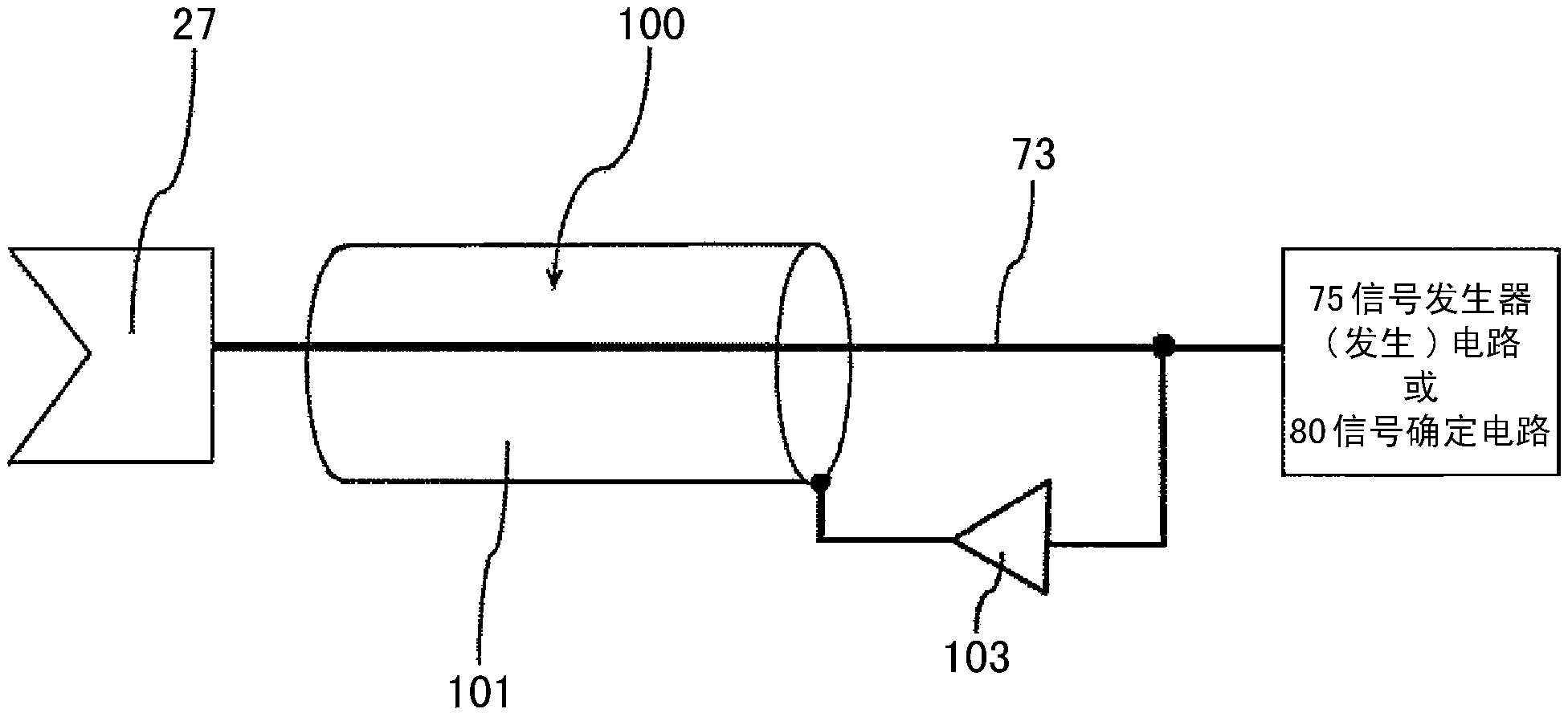

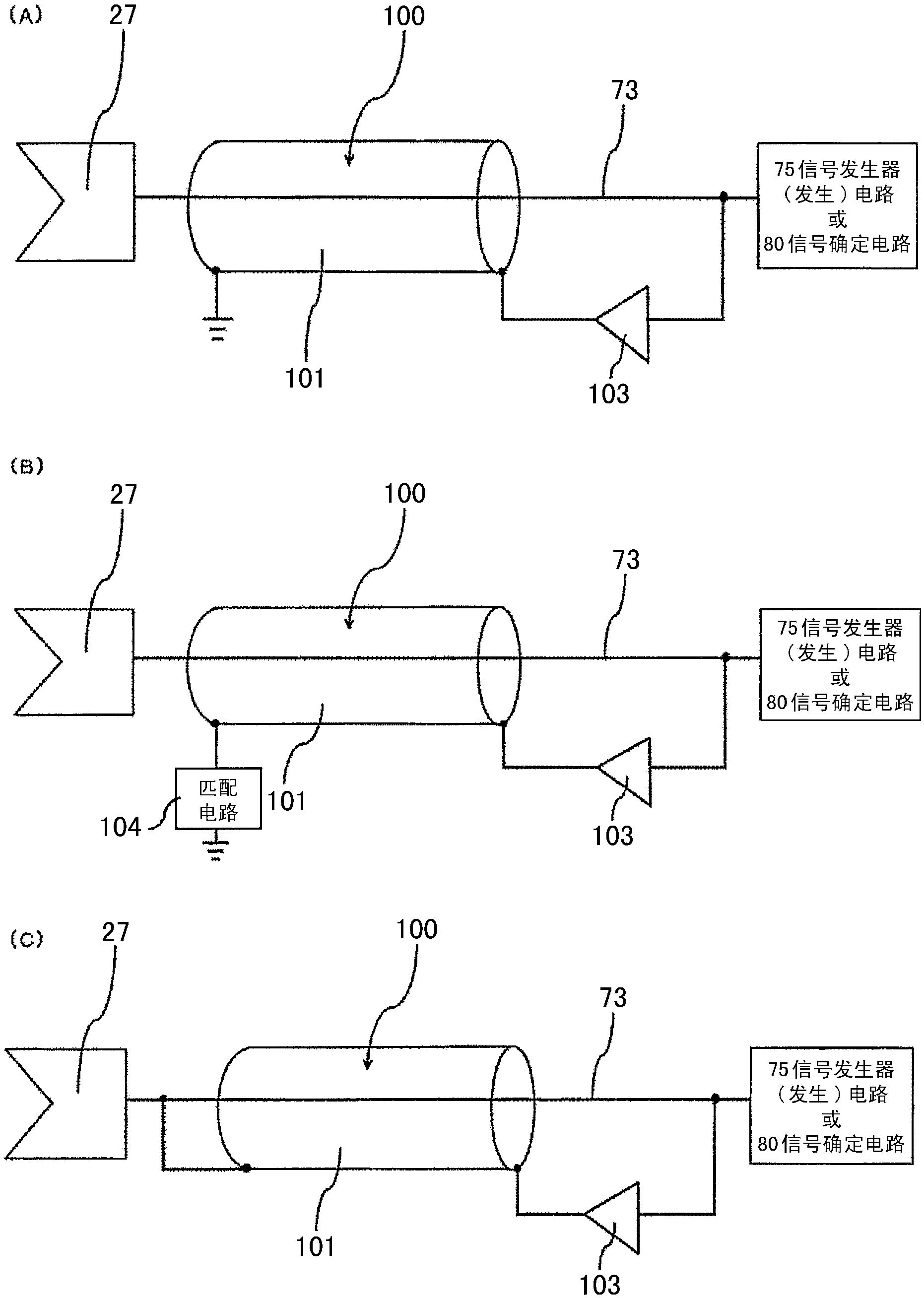

[0042] In the wire stripper of the present invention, the signal applying means may be a buffer circuit that is connected between the electrical signal generator circuit and the signal analyzer circuit and the shielding material of the shielded wire and outputs signals with the same level to The shielding material side of the shielded wire.

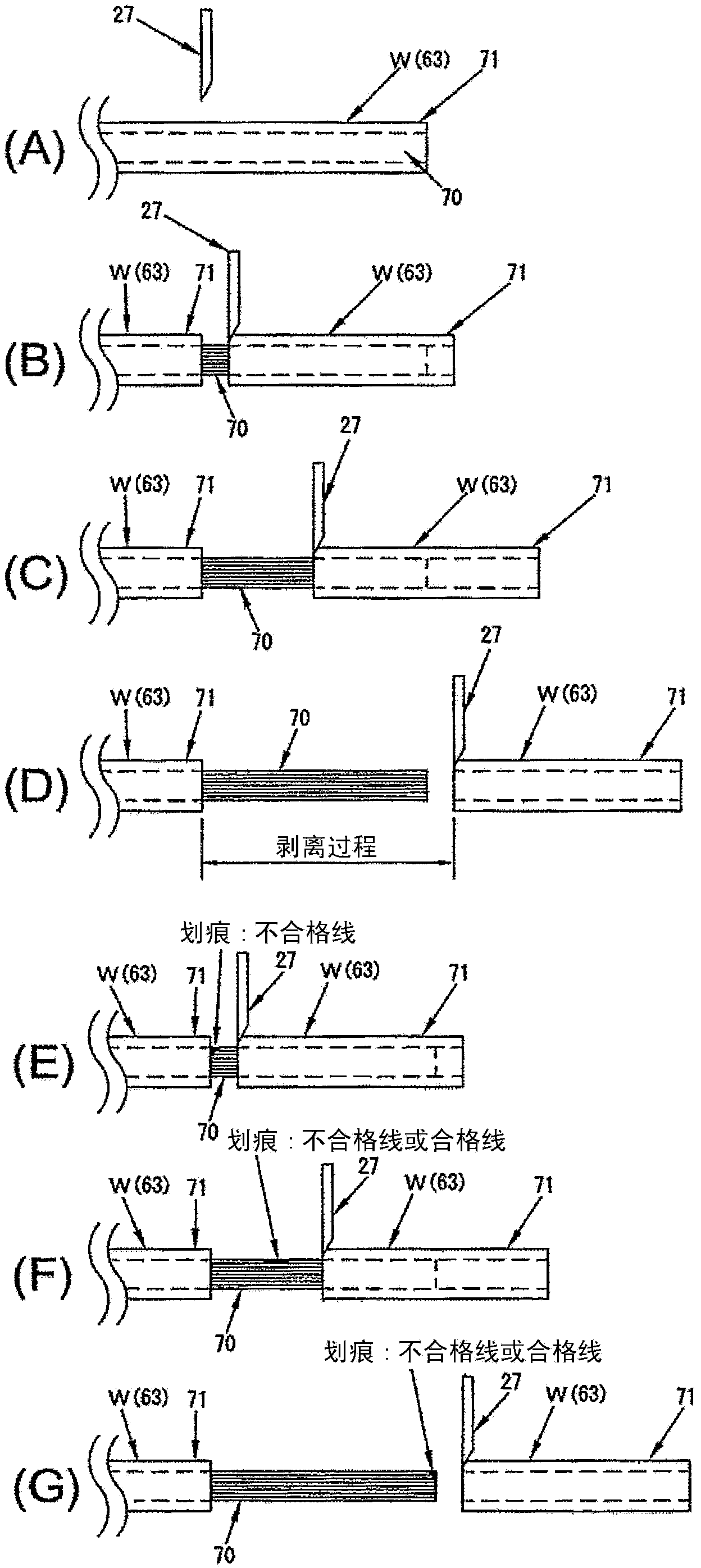

[0043] In addition, when an electric signal is applied to the stripping blade and the stripping blade contacts the core wire of the electric wire, the electric signal changes due to the impedance of the core wire. A function is provided to monitor this phenomenon, wherein said function detects contact between the core wire and the stripping blade.

[0044] Further, it is possible to arbitrarily set the timing or period of time when detecting whether the stripping blade touches the core wire and monitor the time such as starting the stripping operation, just before the end of the stripping operation or during the end of the stripping opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com