Sheep debristling machine

A hair planing machine and hair planing technology, applied in slaughtering accessories, slaughtering, slaughtering devices and other directions, can solve the problems of poor use effect, high labor intensity, low degree of automation, etc., to improve efficiency and sanitation, and reduce work intensity. and job difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

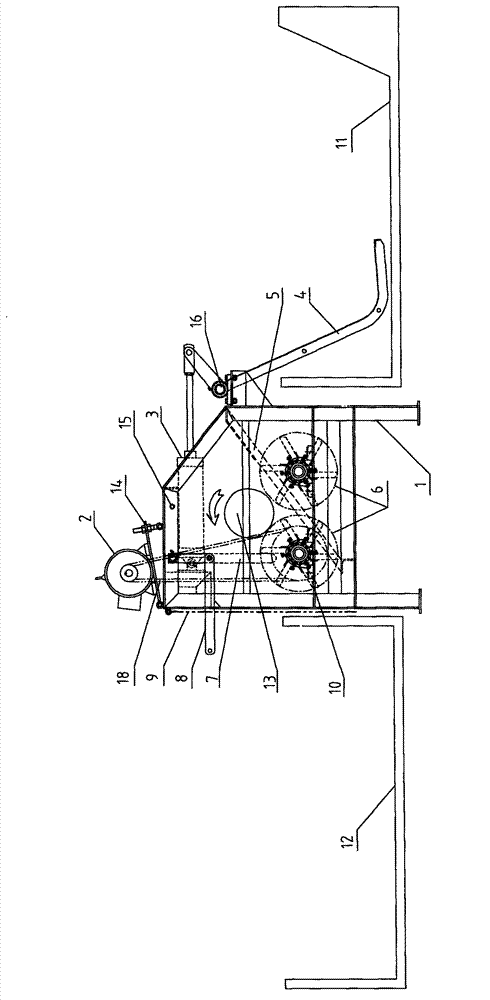

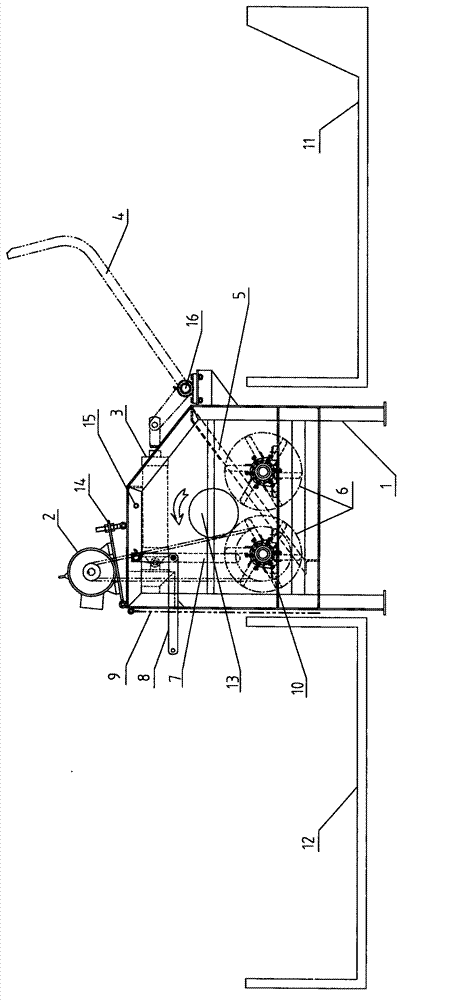

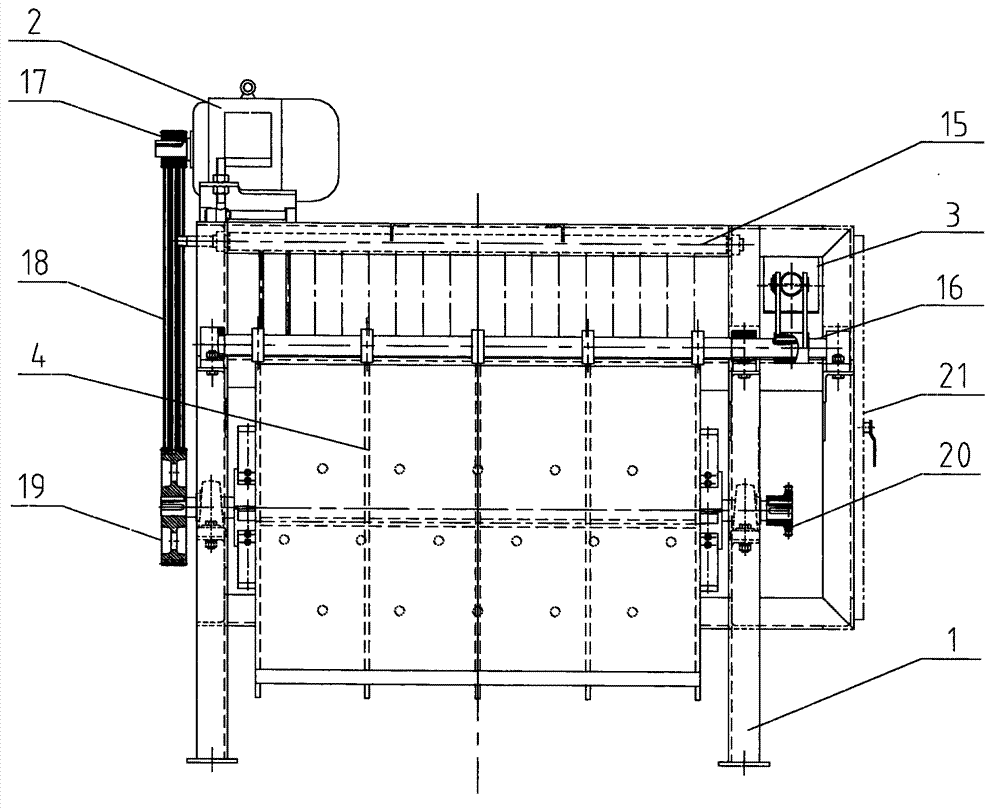

[0018] Such as figure 1 , figure 2 , image 3 Shown is a sheep shaving machine, including a galvanized frame 1, a motor 2, a rake 4, a rake driving device for driving the rake 4 to rotate, a sheep fence 5, two shaving rollers 6, hot water The shower device 15, the scalding pool 11 and the clean water pool 12, the housing of the motor 2, the cylinder 3 and the sheep fence 5 are uniformly fixed on the frame 1, and the sheep fence 5 is provided with a sheep fence at the exit of the sheep fence 5. The door 7 and the hot water shower device are positioned above the sheep fence 5; the output shaft of the motor 2 is connected with the rotating shafts of the two shaving rollers 6 through the transmission device, and the rotation directions of the two shaving rollers 6 are consistent and uniform. Facing the gate 7 of the sheep fence, a shaving block 10 is arranged on the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com