Grease for substituting lard and preparation method thereof

A technology of oil and mixed oil, applied in the field of edible oil, can solve problems such as increasing the risk of users, and achieve the effects of reducing blood lipid diseases, reducing saturated fatty acids, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Preparation method of oil composition

[0077] In the present invention, the preparation method of oil composition comprises the following steps:

[0078] Combine the fat and stir.

[0079] In the present invention, the methods of mixing and stirring oils and fats are well known to those of ordinary skill in the art, and the specific parameters that need to be adopted, such as mixing mode, stirring timing, stirring speed, etc., are all conventional, and those of ordinary skill in the art According to the description of the present invention combined with the prior art, personnel can directly determine the specific constants of stirring, so as to obtain a uniformly mixed oil composition. Specifically, in one embodiment of the present invention, the mixing method can be to add the cottonseed oil fractionation solid fat to the palm oil, or to add the cottonseed oil fractionation solid fat to the palm oil, or to add the cottonseed oil fractionation solid fat and palm oil ...

Embodiment 1

[0117] Embodiment 1, raw material preparation

[0118] 1.1. Preparation of solid fat from cottonseed oil

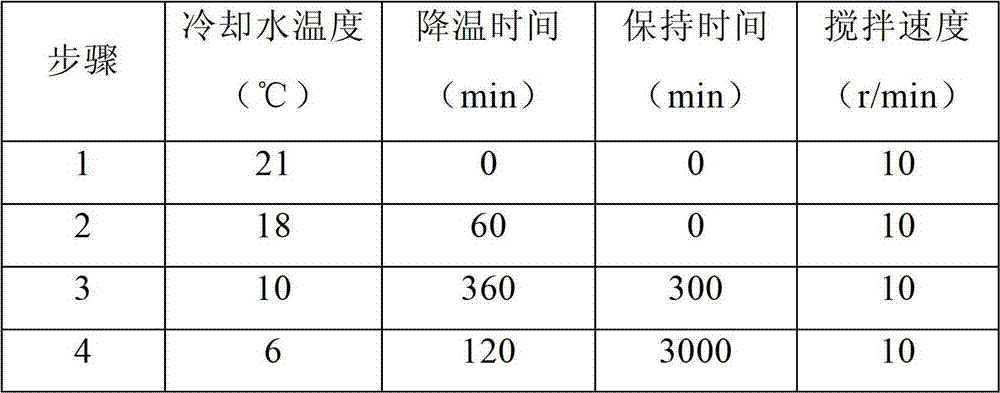

[0119] Secondary cottonseed oil was fractionated according to the conditions in Table 1 to obtain cottonseed oil stearin.

[0120] Table 1, Secondary cottonseed oil fractionation cottonseed oil stearin program

[0121]

[0122] After the temperature dropped to 6°C, start to observe the crystallization state in the crystallization tank. After the crystallization was completed, press filter. After testing, the melting point was 24.1°C.

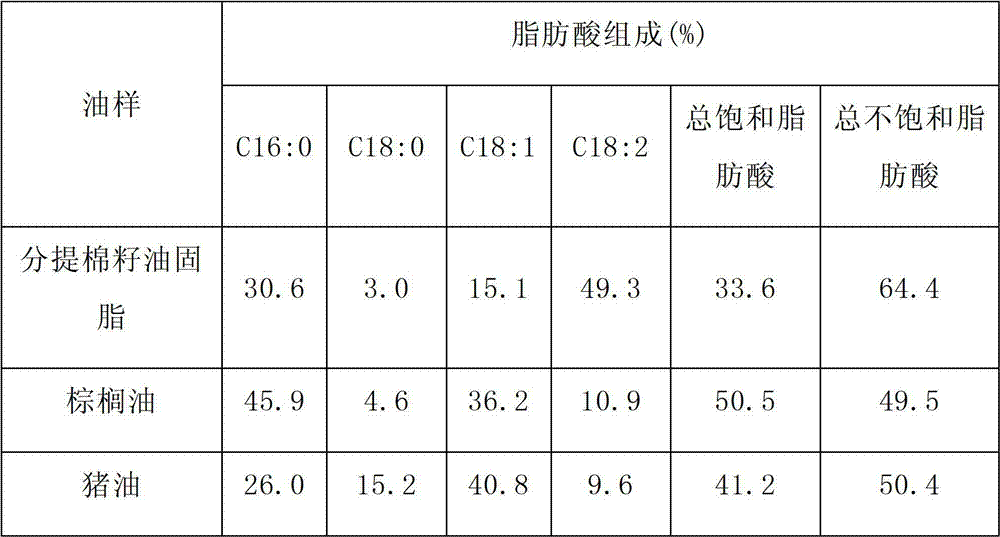

[0123] The physicochemical properties (results are shown in Table 2) and fatty acid composition (results are shown in Table 3) of palm oil, lard and the fractionated cottonseed oil solid fat prepared in Example 1.1 were respectively detected.

[0124] Table 2. Physicochemical properties of fractionated cottonseed oil solids, palm oil and lard

[0125] Physical and chemical indicators

Fractionated Cottonseed Oil Solid Fat ...

Embodiment 2-9

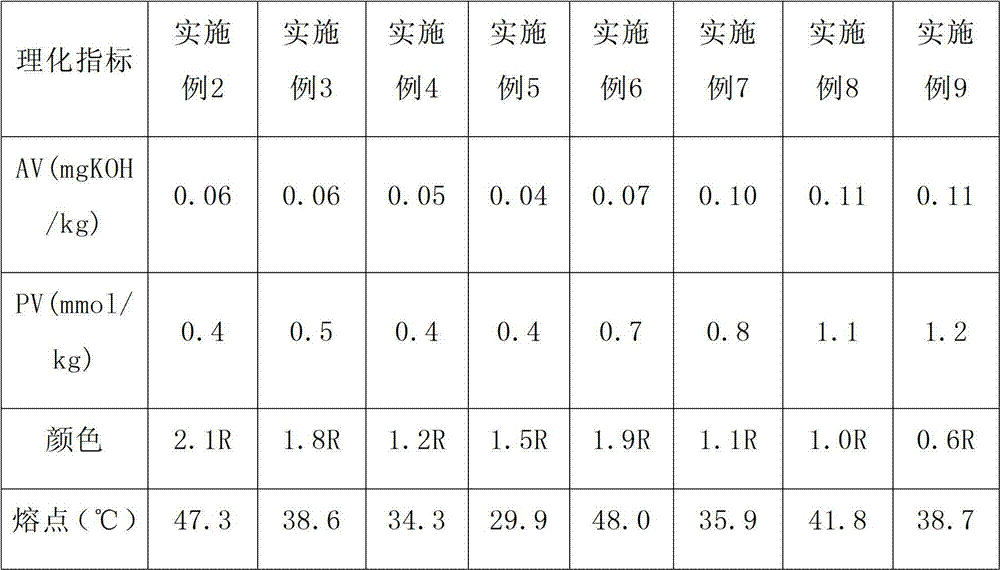

[0129] Embodiment 2-9, preparation of mixed oil

[0130] According to the composition in Table 3, the corresponding oils were mixed, stirred evenly, and the mixed oils were prepared, and the physicochemical properties and fatty acid composition of the obtained oils were tested, and the results were shown in Tables 4 and 5, respectively.

[0131] Table 3. Mixing ratio

[0132] Numbering

Composition of oil mixture

Example 2

20% hard cottonseed oil + 80% palm oil

Example 3

50% hard cottonseed oil + 50% palm oil

Example 4

65% hard cottonseed oil + 35% palm oil

Example 5

80% hard cottonseed oil + 20% palm oil

Example 6

10% hard cottonseed oil + 75% palm oil + 15% lard

Example 7

35% hard cottonseed oil + 15% palm oil + 50% lard

Example 8

5% hard cottonseed oil + 25% palm oil + 70% lard

Example 9

6% hard cottonseed oil + 4% palm oil + 90% lard

[0133] Table 4. Physicochemical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com