Lard-based general shortening and preparation method thereof

A technology of shortening and lard, applied in the fields of application, edible oil/fat, fatty acid production, etc., can solve the problems of many chemical reaction by-products, difficult control of reaction by-products, rough crystallization of lard oil, etc., and achieve Shortened production time, shortened hydrogenation time, good crisping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

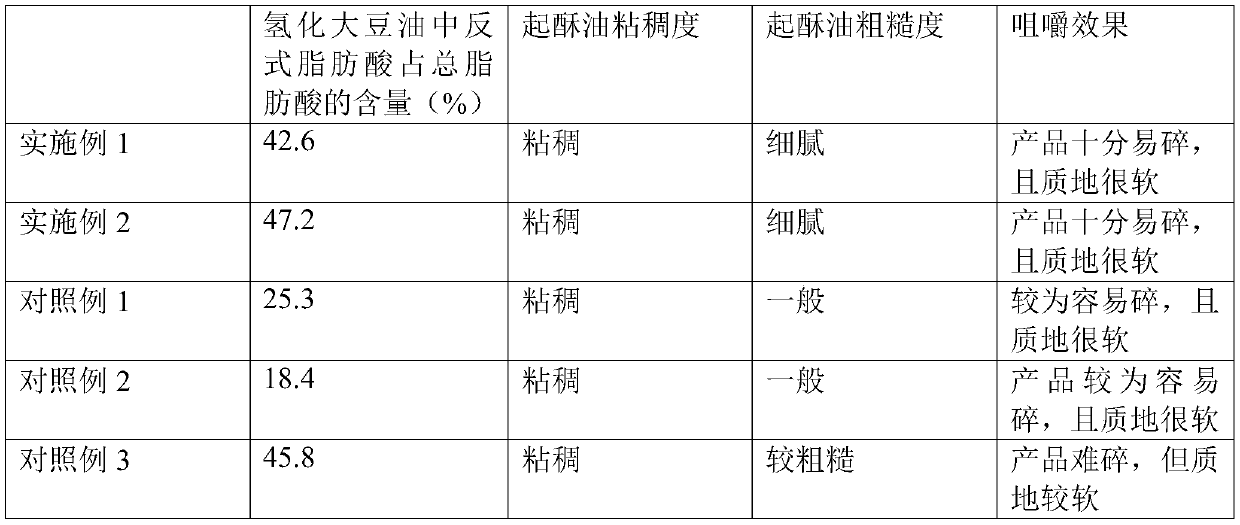

Examples

Embodiment 1

[0016] Among the raw materials used in the preparation of shortening in the present invention, hydrogenated oil is hydrogenated soybean oil, and the preparation method of hydrogenated soybean oil is as follows: soybean oil and foamed nickel are put into the reactor at a mass ratio of 100:3.5, and then the reactor is evacuated to -0.1Mpa, then inject hydrogen into the reactor to 100Kpa, vacuumize the reactor to -0.1Mpa again, then inject a mixture of hydrogen and methane gas with a volume ratio of 92:8 to 2.0Mpa in the reactor, and Heat the reactor to 95°C, magnetically stir at 1300r / min, and react for 15 minutes. After the reaction, continue magnetic stirring, cool the reactor to 60°C naturally, vacuumize the inside of the reactor to -0.1Mpa, and then inject air, repeat three times, The nickel foam was filtered out, and the liquid was naturally cooled to 20°C to obtain hydrogenated soybean oil.

[0017] Before using the nickel foam, heat the nickel foam to 300°C in a mixed gas...

Embodiment 2

[0021] The preparation method and steps of other raw materials are the same as in Example 1. The preparation method of lard-based general-purpose shortening is as follows: first, 60 kg of lard, 4 kg of sodium caseinate, 30 kg of hydrogenated oil and 12 kg of 56-degree palm stearin are placed in a reaction kettle Heat to 50°C, then add 6kg of modified immobilized lipase, then heat to 65°C, vacuumize to 0.1Mpa under magnetic stirring 400r / min, react for 2 hours, then fill the reactor with nitrogen constant pressure, filter Remove the immobilized lipase and cool to 20°C to obtain lard-based general-purpose shortening.

[0022] The modified immobilized lipase is modified with maltose solution. When modifying, the immobilized lipase Lipozyme IM-60 is immersed in an aqueous solution containing 35 wt% maltose at 30°C for 10 minutes, then filtered, and air-dried at 60°C for 15 minutes to obtain the modified lipase immobilized lipase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com