Building garbage treatment system

A technology for processing system and construction waste, which is applied in the direction of construction waste recycling, recycling technology, solid waste removal, etc., can solve the problems of many transfer links, large floor space, low efficiency, etc. Effect of area reduction and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

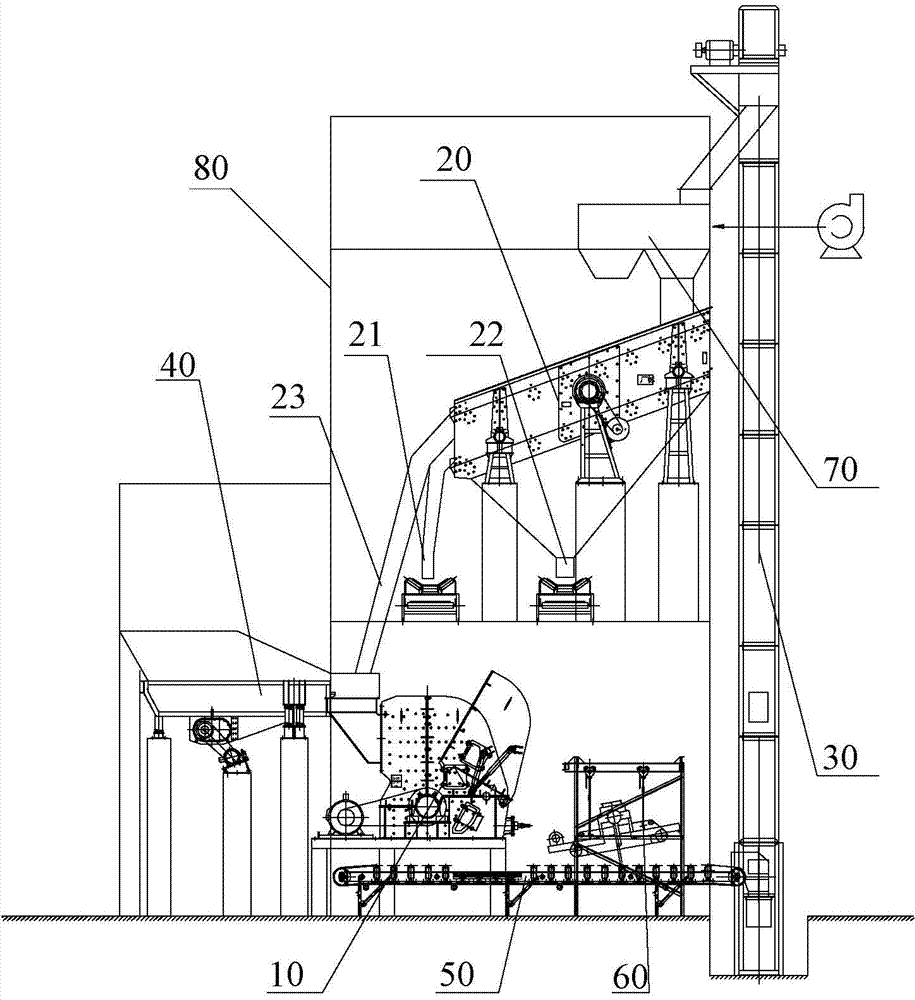

[0018] Such as figure 1 As shown, the construction waste treatment system according to the present invention includes: crushing equipment 10; screening equipment 20, which is arranged above the crushing equipment 10, and has a downwardly arranged material slide; The discharge is lifted to a screening device 20 . In the present invention, since the screening equipment 20 is arranged above the crushing equipment 10, the footprint of the entire processing system is effectively reduced. In addition, due to the height difference between the screening equipment 20 and other equipment, the material naturally slides down under the action of gravity. For example, the return material of the screening equipment 20 automatically falls back to the crushing equipment 10 through the return slideway, reducing the number of conveying equipment. Improve efficiency. Gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com