Screw-type nail extractor specifically for railway signal

A technology for railway signal and nail puller, which is applied to nail pullers, manufacturing tools and other directions, can solve the problems of bulky, inconvenient and unsafe nail pullers, and achieve the effects of low production cost, simple structure and lightening of load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

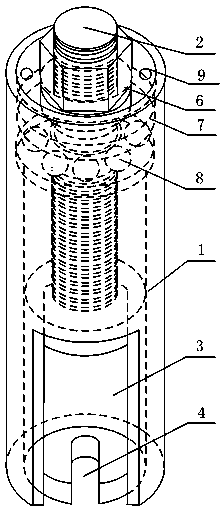

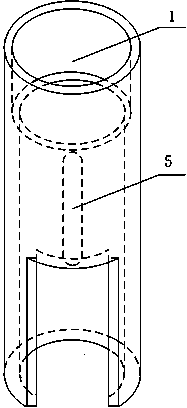

[0033] Such as figure 1 and figure 2 As shown, the special-purpose rotary nail puller for railway signals includes a support sleeve 1 and a puller rod accommodated inside the support sleeve 1. The puller rod includes a screw rod 2. The side of the screw rod 2 is provided with threads. Nail chamber 3, a rotary disk that is threadedly connected to the outer side of the upper end of the screw rod 2 and movably connected to the inner side of the upper end of the support sleeve 1. The screw rod 2 and the staple chamber 3 are of an integrated structure, and the outer side of the staple chamber 3 is movably connected to the inner side of the support sleeve 1 , In this example, the side of the screw 2 is set as a trapezoidal thread.

[0034] In order not to damage the conductive wire connected to the plug during the operation and to easily withdraw after the plug is pulled out, the staple chamber 3 is set as a hollow cylindrical structure, and the side is provided with an opening, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com