Method for preparing alpha-phase porous flaky nickel hydroxide microspheres

A nickel hydroxide and flake technology, applied in the field of preparing nickel hydroxide microspheres, can solve problems such as toxic cost and long reaction time, and achieve the effects of short production cycle, low production cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 0.02mol of nickel nitrate, then add 500mL of distilled water, stir to fully dissolve, add 0.02mol of hexamethylenetetramine at room temperature, stir and dissolve evenly, add to the reaction kettle, seal it and react at 150°C for 1 hour. After the reaction, the product was filtered, washed repeatedly with water, and dried at 120° C. to obtain α-phase porous sheet-shaped nickel hydroxide microspheres.

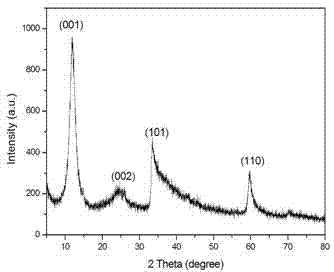

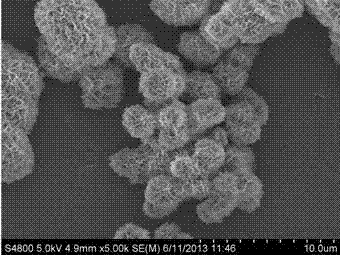

[0028] The crystal phase structure of the product was characterized by Shimadzu XRD-6000 X-ray powder diffractometer (XRD), using Cu Kα rays with a wavelength of 0.15406 nm, tube voltage 40kV, tube current 40mA; using Hitachi S-4800 scanning electron A microscope (SEM) was used to observe the morphology of the product, and the working voltage was 5kV.

[0029] The XRD patterns and SEM photos of the obtained α-phase porous nickel hydroxide microspheres are shown in figure 1 and figure 2 According to the results of XRD pattern analysis, the product is pure α-phase n...

Embodiment 2

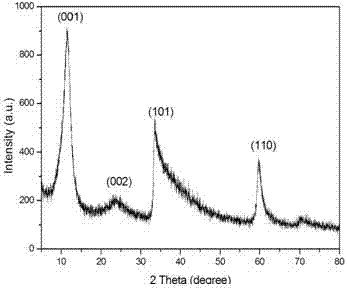

[0031] Take 0.02 mol of nickel chloride, then add 200 mL of distilled water, stir to fully dissolve, add 0.03 mol of hexamethylenetetramine at room temperature, stir and dissolve evenly, add to the reaction kettle, seal it and react at 180°C for 2 hours. After the reaction, the product was filtered, washed repeatedly with water, and dried at 100° C. to obtain α-phase porous sheet-shaped nickel hydroxide microspheres.

[0032] The XRD spectrum and the microscopic SEM photos of the obtained α-phase porous sheet-like nickel hydroxide microspheres, such as image 3 and Figure 4 shown by image 3 and Figure 4 It can be seen that the product has high purity, uniform shape, and a size of 2 to 4 microns.

Embodiment 3

[0034] Take 0.02mol of nickel acetate, then add 50mL of distilled water, stir to fully dissolve, add 0.04mol of hexamethylenetetramine at room temperature, stir and dissolve evenly, add to the reaction kettle, seal it and react at 200°C for 1 hour. After the reaction, the product was filtered, washed repeatedly with water, and dried at 80° C. to obtain α-phase porous sheet-shaped nickel hydroxide microspheres.

[0035] XRD of the obtained α-phase porous nickel hydroxide microspheres diffraction Atlas and microscopic SEM photos, such as Figure 5 and Image 6 shown by Figure 5 and Image 6 It can be seen that the product has high purity, uniform shape, and a size of 4-6 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap