Device and method for drawing out fibers from fiber bundles and tidily collecting fibers

A fiber collection and fiber bundle technology, applied in textiles and papermaking, etc., can solve problems such as affecting development opportunities, low efficiency, shortage of skilled employees, etc., to reduce the difficulty of production technology and labor intensity, easy and safe operation, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

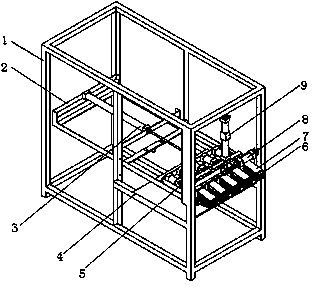

[0043] Such as figure 1 , figure 2 , Figure 4As shown, the equipment for extracting fibers from fiber bundles and neatly collecting them has a simple structure, is easy to use, and can realize mechanized fiber extraction and neatly collecting. The method for extracting fibers from fiber bundles and neatly collecting them does not cause any damage to the fibers. Improve work efficiency. The equipment for extracting fibers from fiber bundles and collecting them neatly includes a frame (1) and a positioning platform (2), a fiber collecting platform (4), a telescopic platform (5), a clip system and a positioning system arranged in the frame ;

[0044] One end of the positioning platform (2) is connected to one side of the frame, and the other end of the positioning platform (2) is fixed on the other side of the frame through a positioning system; the telescopic platform (5) is set on the positioning platform One end of the positioning system is connected; the fiber collectio...

Embodiment 2

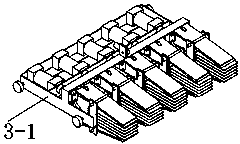

[0091] In this embodiment, the telescopic platform in the equipment is composed of a mobile trolley (3-1), a clip system, etc. The mobile trolley can distribute multiple clip systems side by side in the horizontal and vertical directions, and there can be a certain distance between the clip systems , the size of the interval is matched with the movement of the positioning system, so that the clamp system can meet the requirements of clamping all the fibers in the fiber bundle when the equipment is working.

[0092] The power for the telescopic platform to move back and forth is provided by the telescopic power source. The telescopic power source can be driven by hydraulic pressure, air pressure, motor rotation, magnetic, etc. The trajectory of the telescopic platform is determined by the track between the positioning platform and the mobile car. The range is limited by the telescopic power source, or the telescopic power source is controlled by the program, or is limited by the...

Embodiment 3

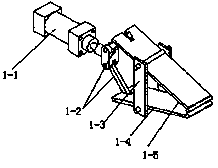

[0095] In this embodiment, the clip system is composed of the clamp system and multi-layer clips in an orderly manner. The opening and closing state of the upper splint and the lower splint of the clamp system determines the opening and closing state of the multi-layer clips, and the clamp system changes itself cyclically. In the working state, the multi-layer clips are opened and closed cyclically. The multi-layer clips are closed to complete the neat extraction of fibers. When the multi-layer clips are opened, the fibers fall neatly on the fiber collection platform.

[0096] Generally speaking, when the hardness of the fiber is relatively large, the width of the multi-layer clip can be appropriately increased. When the fiber is hair or hair as an example, the width of the multi-layer clip is preferably 5-10 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com