A jet-suction anti-tempering anti-explosion cutting torch

An anti-backfire, injection-suction technology, applied in the direction of gas fuel burners, combustion methods, combustion types, etc., can solve the problems of reducing the flow rate of the mixture, limiting the flow rate of the mixture, and decreasing the speed, so as to prevent the backflow of the mixture, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

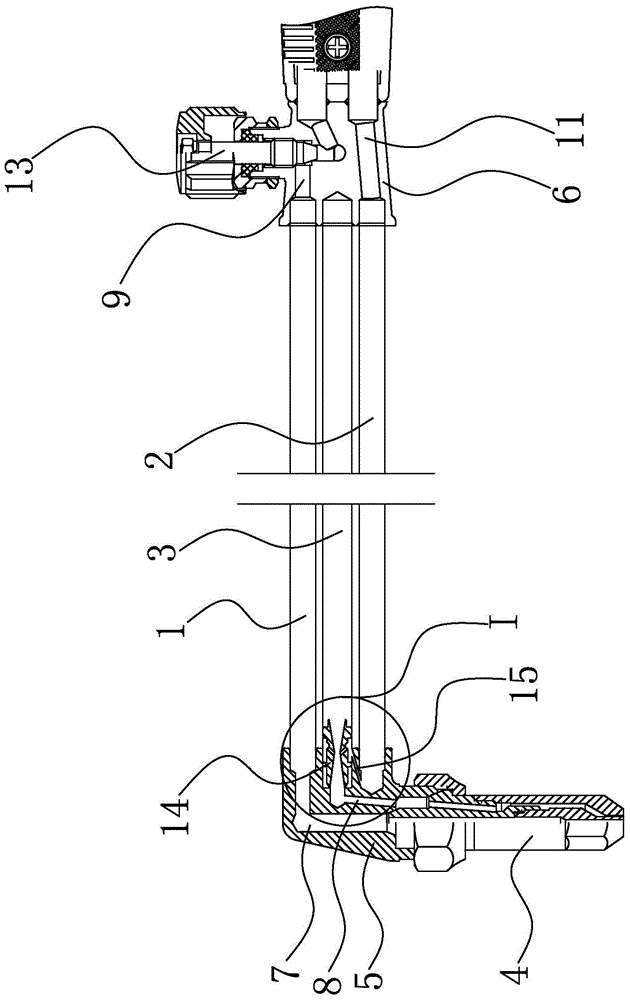

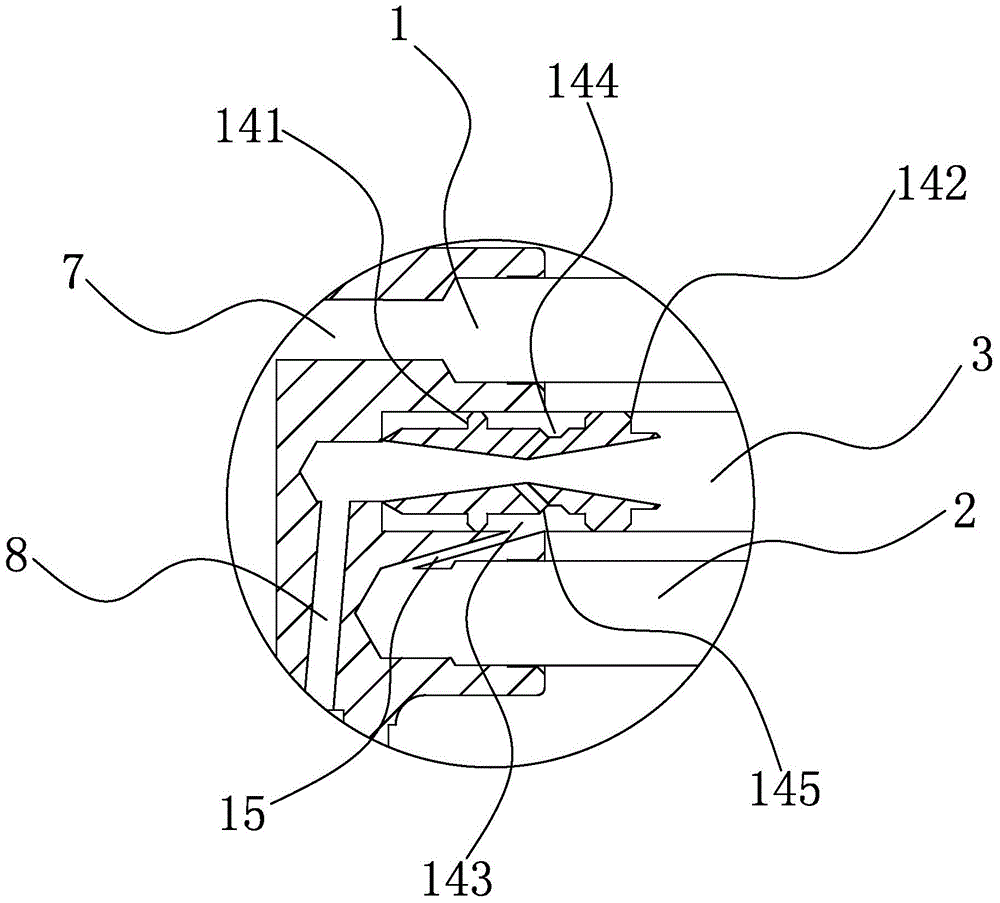

[0027] Embodiment one: if figure 1 , figure 2 and image 3As shown, a jet-suction anti-tempering and anti-explosion cutting torch mainly includes cutting oxygen pipe 1, gas pipe 2, preheating oxygen pipe 3, cutting nozzle 4, cutting nozzle joint 5, middle body 6, and cutting nozzle 4 is installed on On the cutting nozzle joint 5, there are cutting oxygen passages 7 and mixed gas passages 8 inside the cutting nozzle 4 and the cutting nozzle joint 5, and they are connected correspondingly. Road 9 is the oxygen main pipe at the rear of the cutting torch, which is divided into two parts, not shown in the figure) and gas gas channel 11, and a preheating oxygen regulating valve is installed on the middle body 6 (the structure is the same as that of the cutting oxygen regulating valve 13, as shown in Fig. not shown in ) and the cutting oxygen regulating valve 13, the two ends of the cutting oxygen pipe 1 are respectively connected with the cutting oxygen passage 7 on the cutting n...

Embodiment 2

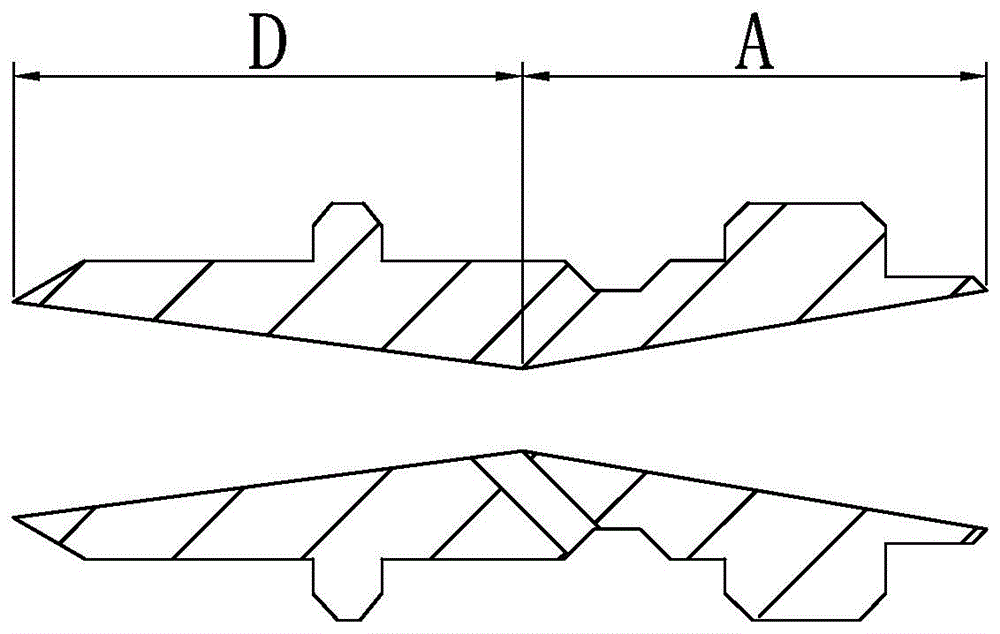

[0034] Embodiment two: if Figure 4 As shown, the overall structure is the same as that of Embodiment 1, the difference is that the inner wall of the nozzle 14 channel is arc-shaped along the axial direction, and along the forward direction of the air flow, a compression section A, an expansion section B and a stable transition section C are formed in sequence, and the compression section A The length is 4mm, the diameter of the inlet end of the compression section A is larger than the diameter of the outlet end of the compression section A, the length of the expansion section B is 3mm, the diameter of the inlet and outlet ends of the expansion section B is the same as the diameter of the outlet end of the compression section A, and the diameter of the expansion section B The diameter of the middle part is slightly smaller than the diameter of the inlet and outlet ends of the expansion section B, and the length of the stable transition section C is 3mm. The diameter of the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com