Combustion monitoring and control system of waste wood fuel boiler without pretreatment process

A pretreatment and boiler technology, applied in the field of waste wood fuel boiler combustion monitoring and control system, can solve the problems of waste wood fuel boiler application difficulties, overburning damage of the grate, inability to adapt to different needs of different fuels, etc. Effects of stabilizing problems and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

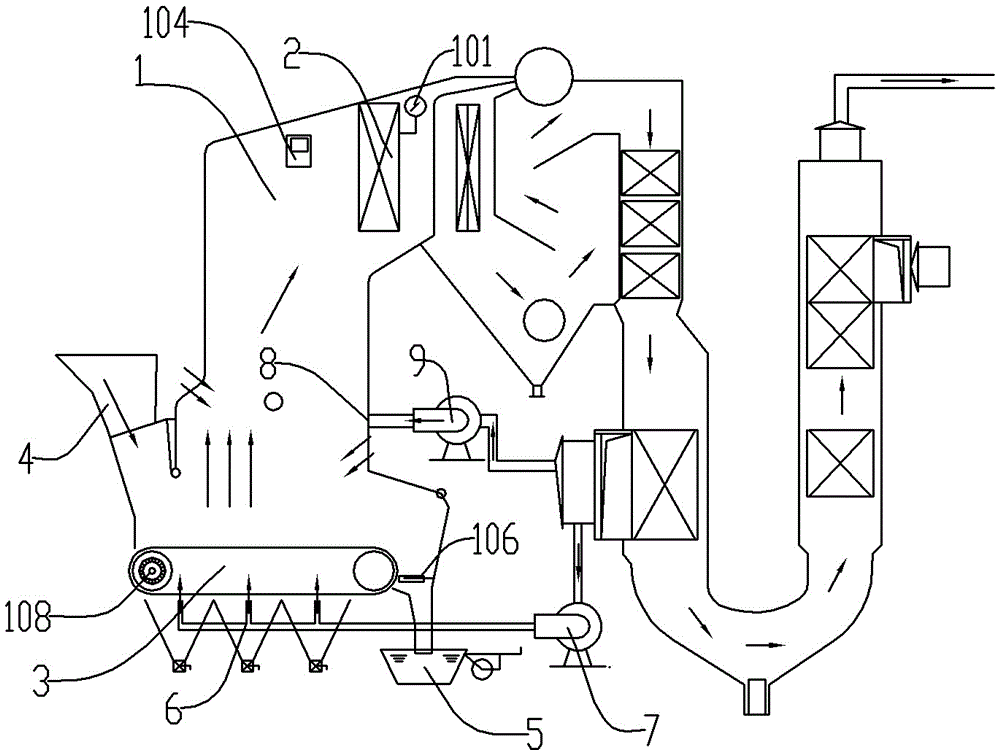

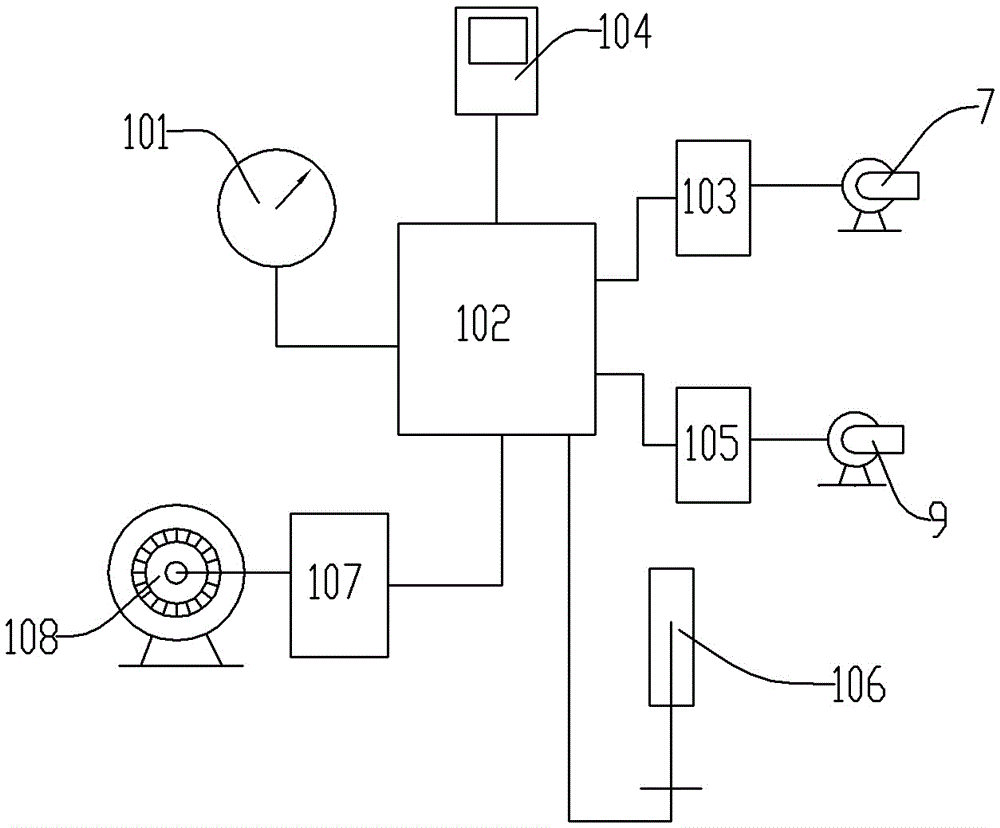

[0014] Such as figure 1 , figure 2 , a combustion monitoring and control system for waste wood fuel boilers without pretreatment process, the steam pipeline 2 is arranged on the top of the boiler furnace 1, the chain grate 3 is arranged at the bottom of the furnace, and the untreated The waste wood is introduced into the funnel-type feeding device 4 in the boiler. The feed port under the funnel-type feed device is opposite to one end of the chain grate, and the fuel entering from the feed port can drop directly or slide along the furnace wall to the grate. One end of the chain grate, the other end of the chain grate has an ash hopper 5 for collecting the ash formed after fuel combustion, and a primary air supply channel 6 is arranged below the chain grate, and the outlet of the primary air supply fan 7 is connected to the primary air supply channel. The air is blown into the furnace through the primary air supply channel under the grate; there is also a secondary air supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com