Drying device for porous fragile granular products

A drying equipment, granular technology, applied in the direction of drying solid materials, drying gas layout, lighting and heating equipment, etc., can solve the problems of short residence time, low yield of finished products, easy breakage, etc., to prolong residence time and save money. The effect of low steam and moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

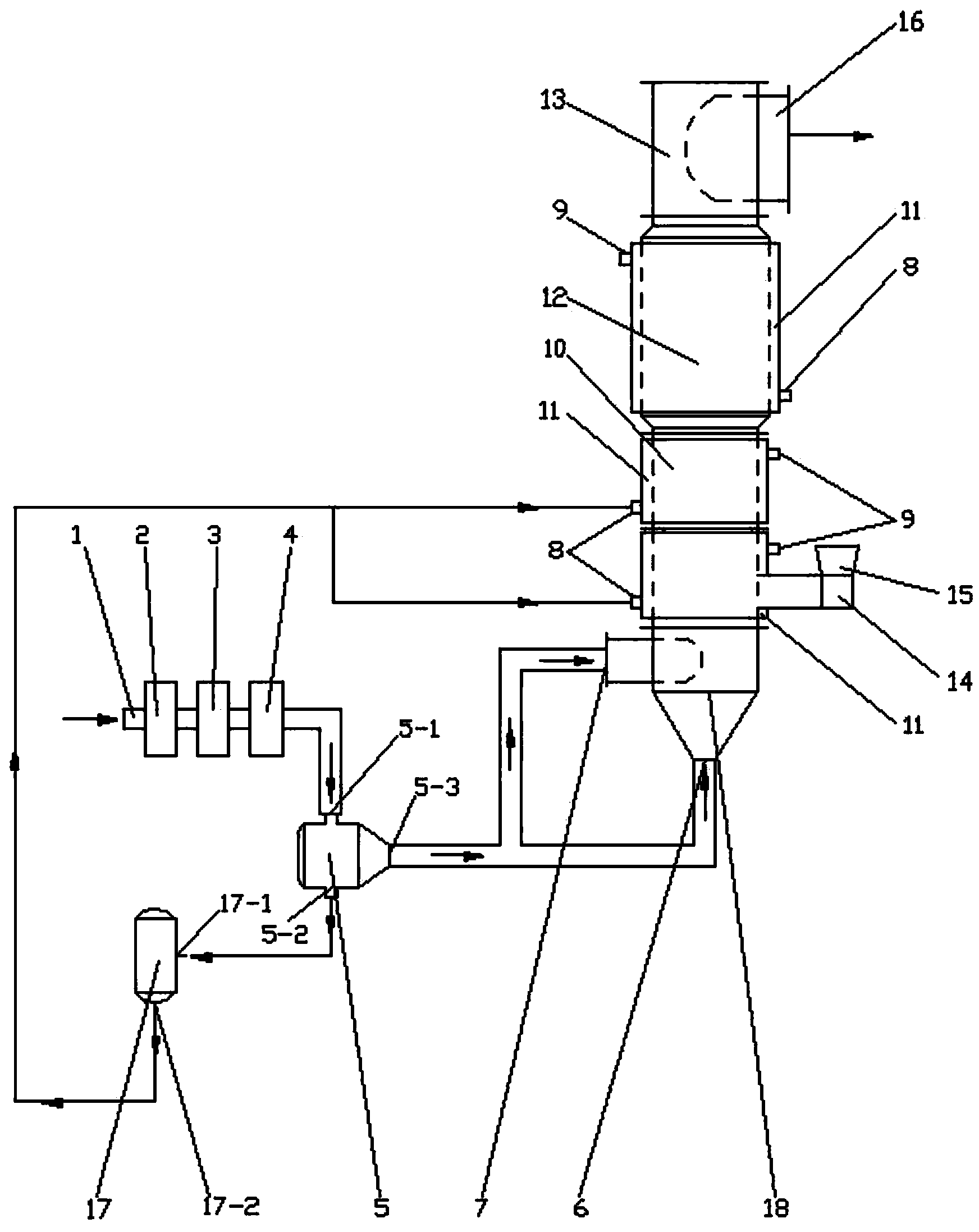

[0014] Such as figure 1 As shown, a drying device for porous and fragile granular products, the airflow drying chamber 18, the material drying chamber 10, and the energy recovery device 13 are connected sequentially from bottom to top, and the air duct 1 passes through the filter 2, fan 3, The gas heater 4 and the steam radiator 5 send hot air into the airflow drying chamber 18, the feeder 14 is placed under the side wall of the material drying chamber 10, the hopper 15 is connected to the feeder 14, and the discharge pipe 16 is placed in the energy recovery device 13 on the side wall; the hot air enters from the hot air inlet 5-1, and after being discharged from the hot air outlet 5-3, it is divided into two branches. The first hot air enters the drying chamber from the axial air inlet 6, and the second hot air enters from the tangential direction. The tuyere 7 enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com