A device and method for detecting the effect of road surface compaction

A technology for pavement and compaction thickness, applied in the field of road inspection and construction, can solve the problems of slow core inspection, complicated operation process, long time consumption, etc., and achieve the effect of short test time, simple inspection process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

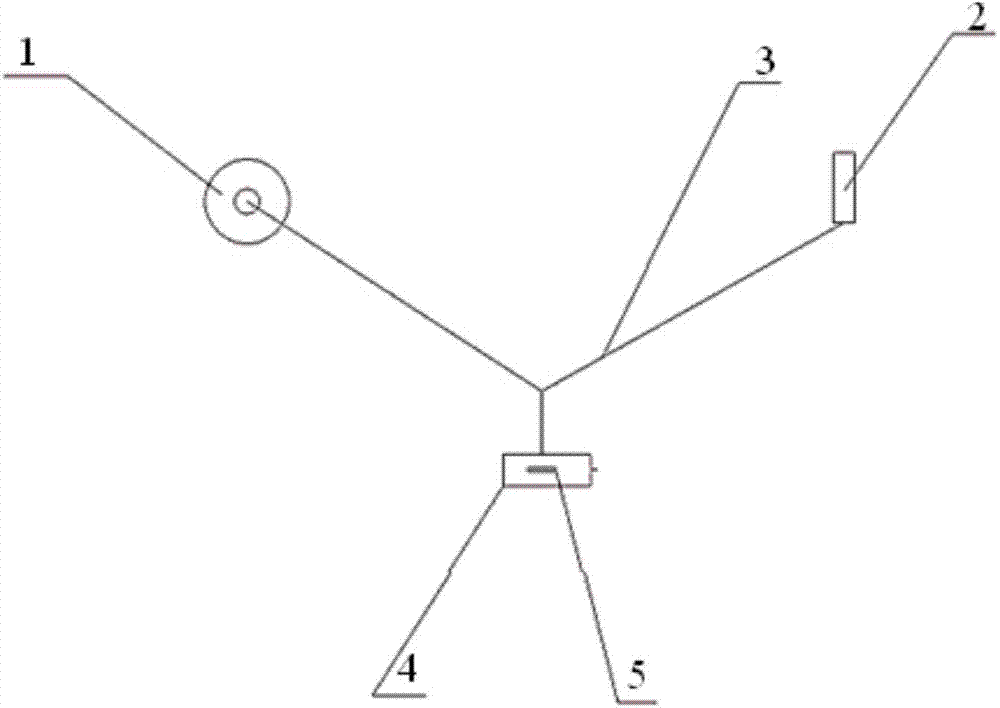

[0022] see figure 1 , the road surface compaction effect detection device of the present invention comprises a pressure sensor 1 for measuring the road surface pressure, a displacement sensor 2 for measuring the thickness of the road surface and a fiber grating demodulator 4, the pressure sensor 1, the displacement sensor 2 and Fiber Bragg grating demodulator 4 is connected by cable 3; Wherein, pressure sensor 1 among the present invention is disk type pressure sensor 1, and its effect is to draw after pavement paving is finished and in compaction process and compaction finish The post-dynamic pressure F; the function of the cable 3 is to serve as a bridge for data transmission between the disc pressure sensor 1, the displacement sensor 2 and the fiber grating demodulator 4; the function of the displacement sensor 2 is to measure the The compaction thickness after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com