Triaxial micromachine accelerometer static correction method based on particle swarm optimization

A technology of particle swarm optimization and accelerometer, applied in speed/acceleration/shock measurement, testing/calibration of speed/acceleration/shock measurement equipment, measurement devices, etc., can solve the problem of being easily disturbed by random errors, and the correction process is complex and cumbersome , the cost of the rotating platform is exceeded, etc., to achieve the effects of improving measurement accuracy, easy implementation, and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in more detail:

[0019] In the experiment, the three-axis accelerometer ADXL345 produced by ADI Company is used. Here it is set to 13-bit A / D conversion, the measurement accuracy is 3.9mg / LSB, and the range is -2g~2g, so 1g=255Counts.

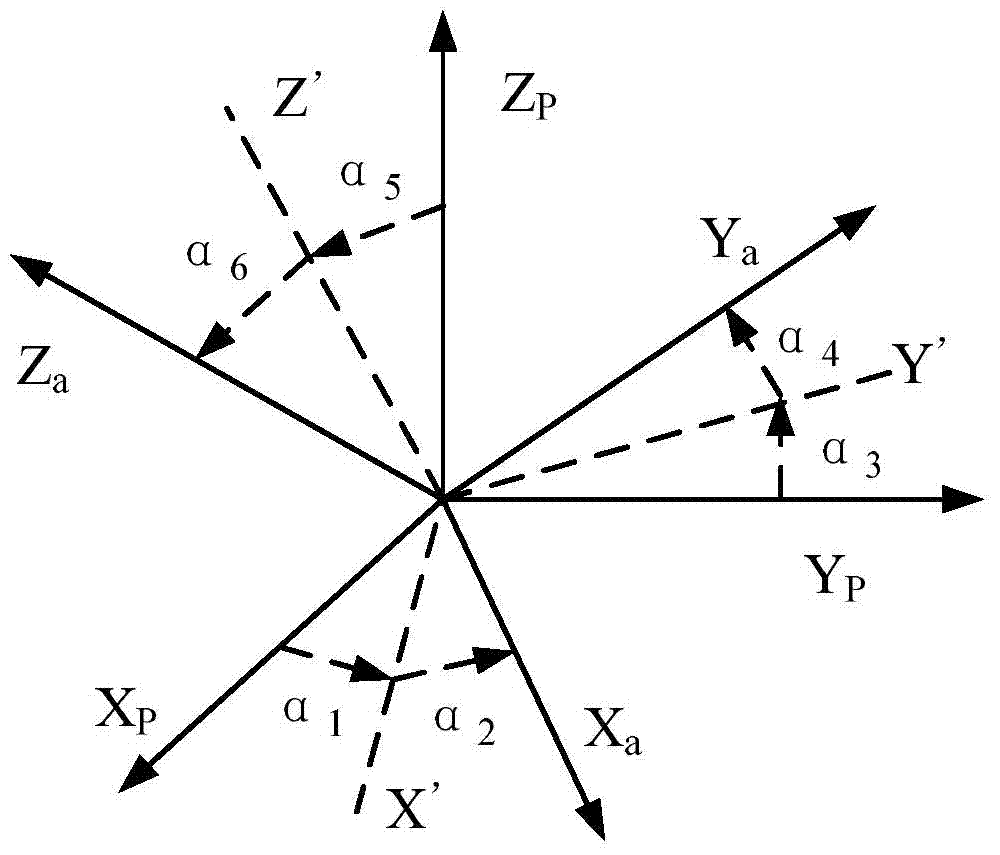

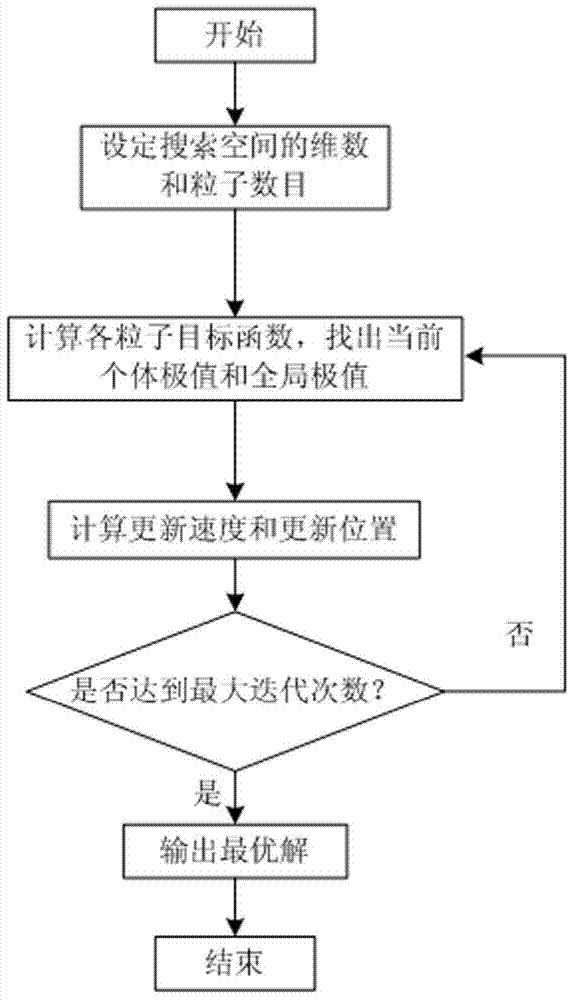

[0020] A method for static correction of three-axis micromachined accelerometers based on particle swarm optimization, such as Figure 4 As shown, its content includes the following steps:

[0021] The first step is to fix the accelerometer control circuit and the carrier, and keep its Z axis parallel to the vertical line of the carrier plane as much as possible, and the XY plane parallel to the carrier plane to reduce installation errors. Ensure that the circuit board can rotate freely in three axes in space.

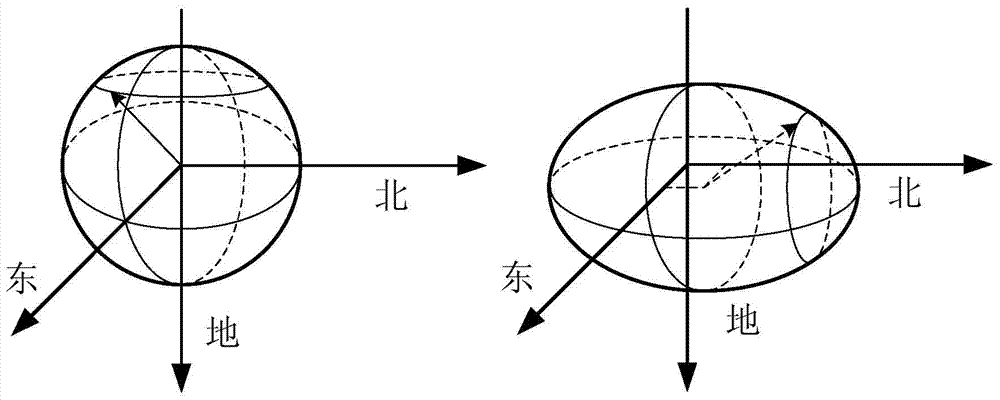

[0022] The second step is to manually drive the circuit board and the carrier with the accelerometer to rotate in space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com