A Floating Filament Grid Modulator

A modulator and grid technology, which is applied in the field of floating filament grid modulators, can solve the problems of inadequate protection measures, complex implementation methods, and large volume, and achieve the effects of perfect protection measures, low power consumption, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

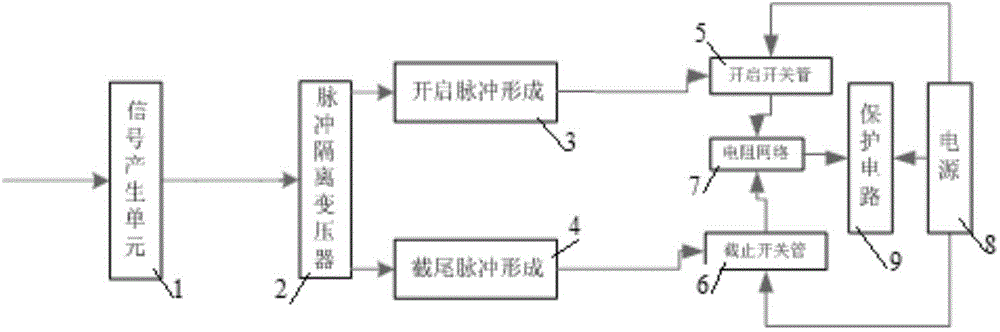

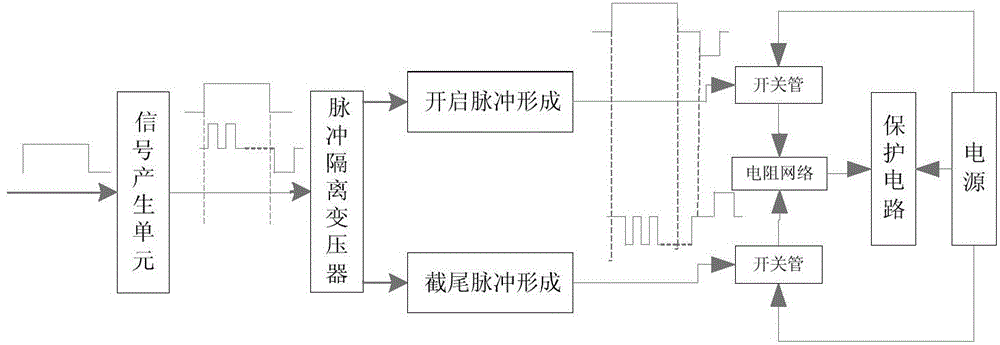

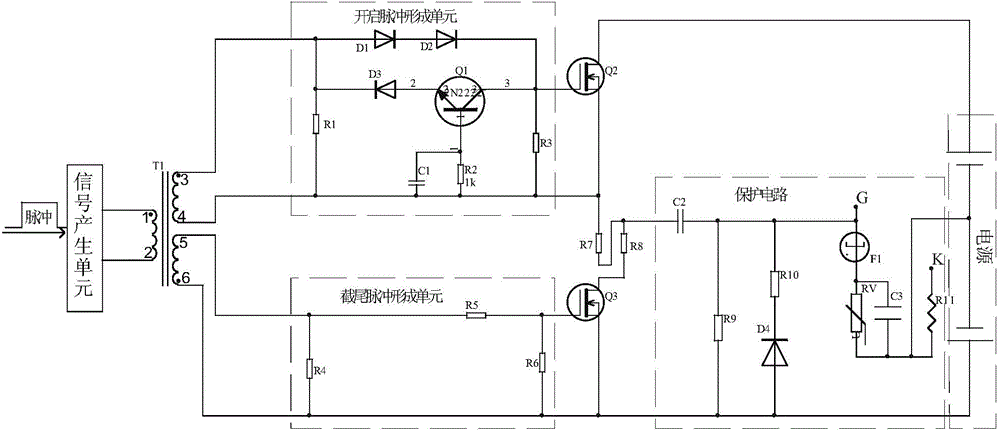

[0029] Such as figure 1 As shown, the floating filament grid modulator of the present invention includes:

[0030] A signal generating unit 1, configured to generate pulse signals, including leading edge pulses, trailing edge pulses and supplementary pulses;

[0031] Pulse isolation transformer 2, used to transmit pulse signals and isolate high and low voltage;

[0032] The opening pulse forming unit 3 is used to generate the opening pulse according to the leading edge pulse and the supplementary pulse;

[0033] A truncated pulse forming unit 4, configured to generate a truncated pulse according to the trailing edge pulse;

[0034] Turn on the MOS transistor 5 to turn on the turn-on voltage according to the turn-on pulse;

[0035] cut-off MOS transistor 6, used to turn on the cut-off voltage according to the truncated pulse;

[0036] Resistor network 7, used for current limiting and output voltage;

[0037] The power supply 8 is used to provide power for turning on the MO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com