Instant concentrated mixed starch beverage and soup base as well as preparation method and eating method thereof

A technology for concentrating pulp and soup, applied in the field of beverages and soups, can solve the problems of less development, etc., and achieve the effects of low cost, easy large-scale production, and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

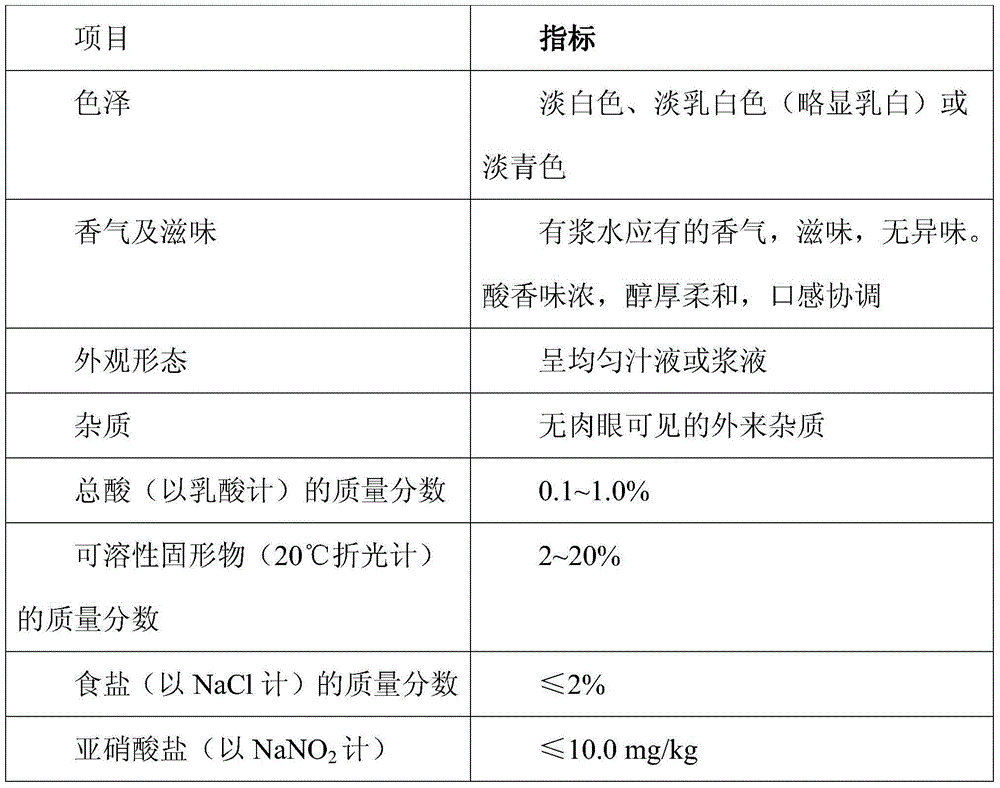

[0030] 1) Selection of pulp water acceptance: check whether the pulp water entering the factory is a mature high-quality pulp water, and the soup juice should be light white, light milky white (slightly milky white) or light blue; the soup has a strong sour aroma, mellow and soft, with The celery has a clear fragrance; the vegetable is tender yellow or yellow-green, translucent and shiny; there is no impurity, no other bad smell, and the vegetable has a certain degree of crispness.

[0031] 2) Initial sterilization: The slurry water is subjected to high-temperature instant sterilization, the sterilization temperature is 150°C, and the sterilization time is 2 seconds.

[0032] 3) Filtration of slurry water: remove the vegetables in the slurry water after the initial sterilization, then pass the slurry water through a 60-mesh double filter to remove the visible particles remaining in the slurry water, and then use an 80-mesh bag filter Perform 2 filtrations.

[0033] 4) Homogen...

Embodiment 2

[0038] 1) Selection of pulp water acceptance: check whether the pulp water entering the factory is a mature high-quality pulp water, and the soup juice should be light white, light milky white (slightly milky white) or light blue; the soup has a strong sour aroma, mellow and soft, with The celery has a clear fragrance; the vegetable is tender yellow or yellow-green, translucent and shiny; there is no impurity, no other bad smell, and the vegetable has a certain degree of crispness.

[0039] 2) Initial sterilization: The slurry water is subjected to high-temperature instant sterilization, the sterilization temperature is 135°C, and the sterilization time is 8 seconds.

[0040] 3) Filtration of slurry water: remove the vegetables in the slurry water after initial sterilization, then pass the slurry water through an 80-mesh double filter to remove the visible particles remaining in the slurry water, and then use an 80-mesh bag filter Perform 2 filtrations.

[0041] 4) Homogeniza...

Embodiment 3

[0046] 1) Selection of pulp water acceptance: check whether the pulp water entering the factory is a mature high-quality pulp water, and the soup juice should be light white, light milky white (slightly milky white) or light blue; the soup has a strong sour aroma, mellow and soft, with The celery has a clear fragrance; the vegetable is tender yellow or yellow-green, translucent and shiny; there is no impurity, no other bad smell, and the vegetable has a certain degree of crispness.

[0047] 2) Initial sterilization: The slurry water is subjected to high-temperature instant sterilization, the sterilization temperature is 140°C, and the sterilization time is 4 seconds.

[0048] 3) Filtration of slurry water: remove the vegetables in the slurry water after the initial sterilization, then pass the slurry water through a 60-mesh double filter to remove the visible particles remaining in the slurry water, and then use a 60-mesh bag filter Perform 2 filtrations.

[0049]4) Homogeniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com