Steel wire coil hoisting clamp

A technology for wire coils and fixtures, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of insecurity and large labor workload, and achieve the effect of reducing labor workload and avoiding hoisting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

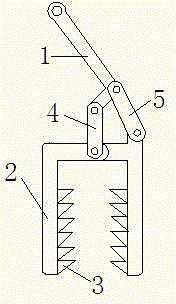

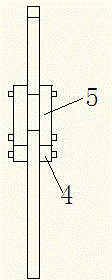

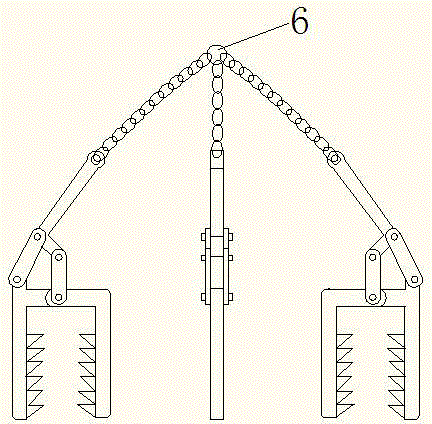

[0014] Attached below figure 1 , 2 3. Through the description of the embodiment, the specific implementation of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the function and working principle of each part, etc. Detailed description: This steel wire coil lifting fixture is composed of at least three lifting units, and the lifting unit includes clamps and iron chains. The clamp is composed of an "L"-shaped operating handle 1, a caliper 2, a connecting rod 4, and a connecting rod 5 to form a quadrilateral hinged structure. Such as figure 2 As shown, there are two connecting rods 4 and 5, which are respectively arranged on both sides of the hinge, so as to increase the stability of the connection of the hinge point of the clamp. The tooth tips on the clamping teeth 3 are set upward at 30 to 70 degrees relative to the vertical edge of the caliper. In practical applications, the clamping effect of the clamp i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com