Polymer polyol preparation method, polymer polyol prepared through the same, and use of polymer polyol

A polyol and polymer technology, applied in the field of slow-rebound polyurethane foam, can solve the problem of less slow-rebound polyurethane foam, and achieve the effects of excellent performance, low resilience and high loss factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

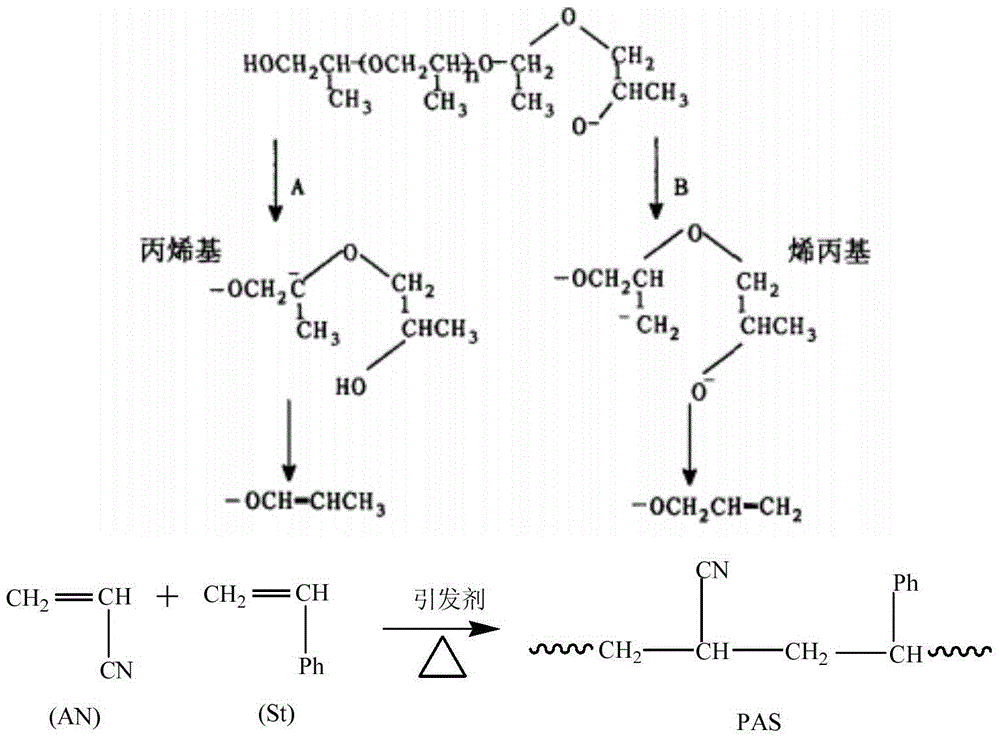

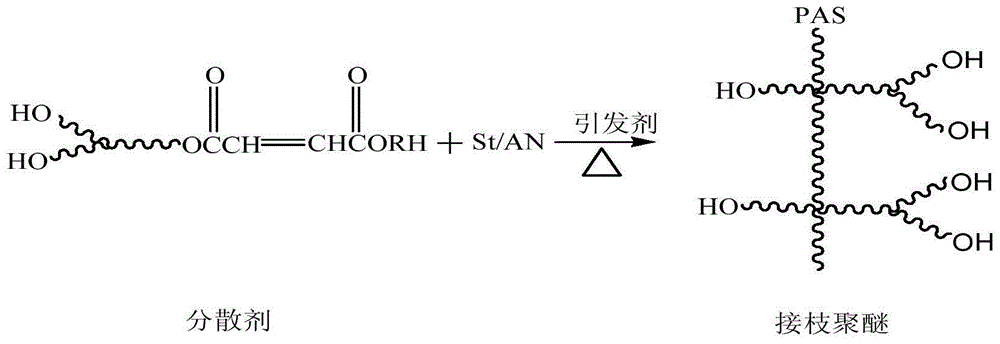

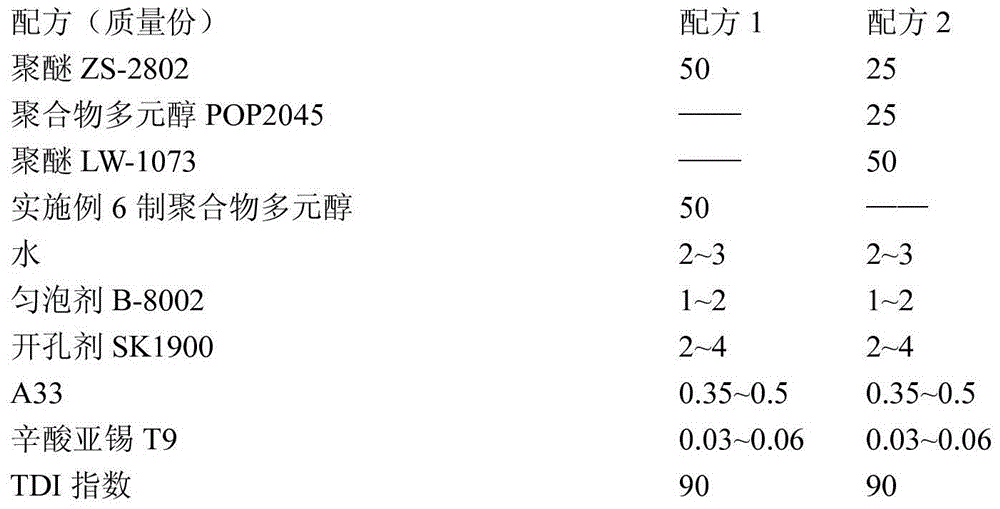

Method used

Image

Examples

preparation example Construction

[0023] Preparation of polymer polyols:

[0024] method 1.

[0025] Batch method: mix high-efficiency dispersant DP-5000, free radical initiator, basic polyether, chain transfer agent, styrene and acrylonitrile, and add dropwise to the reactor. 50-80 minutes, aging for 1 hour after feeding, degassing under reduced pressure for 1 hour, and finally cooling down and discharging to obtain the polymer polyol of the present invention.

[0026] Method 2.

[0027] Continuous method: Add a certain amount of polymer polyol with target solid content into a reaction kettle with a side outlet equipped with a stirring device, a feeder, and a thermometer, and heat the material to heat up. When the temperature is stable at 120°C, The material is added dropwise at a certain feeding speed, and the material is prepared by mixing basic polyether, styrene, acrylonitrile, chain transfer agent, free radical initiator, and self-made high-efficiency dispersant. The residence time is controlled at 5...

Embodiment 1

[0029] Embodiment 1 (prepared by method 1)

[0030] Stir and mix 52g of high-efficiency dispersant DP-50000, 5.6g of free radical initiator, 392g of basic polyether, 52g of chain transfer agent, 168g of styrene and 72g of acrylonitrile, and add dropwise to the reaction kettle. The adding time is controlled at 50-80 minutes, aging for 1 hour after the dropwise addition is completed, degassing under reduced pressure, and cooling for 1 hour to obtain the polymer polyol of the present invention.

[0031] Product indicators: Product appearance: light yellow to white liquid; hydroxyl value: 147mgKOH / g; moisture: 0.05%; acid value: 0.07mgKOH / g; viscosity: 3000mPa.s / 25℃.

Embodiment 2

[0032] Embodiment 2 (prepared by method 1)

[0033] Stir and mix 28g of high-efficiency dispersant DP-5000, 5.6g of free radical initiator, 392g of basic polyether, 52g of chain transfer agent, 168g of styrene and 72g of acrylonitrile, and add dropwise to the reaction kettle. The adding time is controlled at 50-80 minutes, aging for 1 hour after the dropwise addition is completed, degassing under reduced pressure, and cooling for 1 hour to obtain the polymer polyol of the present invention.

[0034] Product indicators: Product appearance: light yellow to white liquid; hydroxyl value: 151mgKOH / g; moisture: 0.05%; acid value: 0.07mgKOH / g; viscosity: 2770mPa.s / 25℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com