A kind of purification method of food grade neutral protease

A neutral protease and purification method technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems of microbial hygiene indicators not meeting the requirements of the food industry, limited application range, low yield of enzyme activity, etc. , to achieve the effect of increasing use value, product added value, high purity and enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

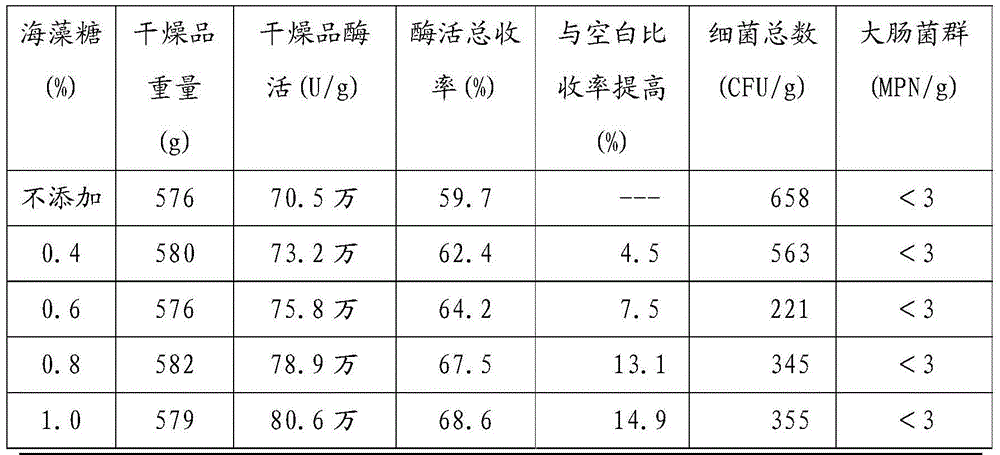

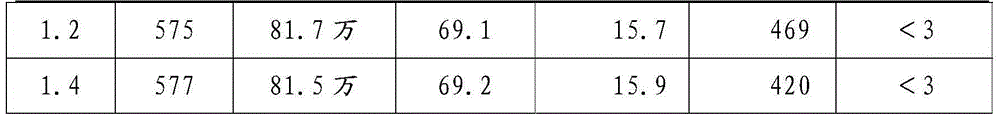

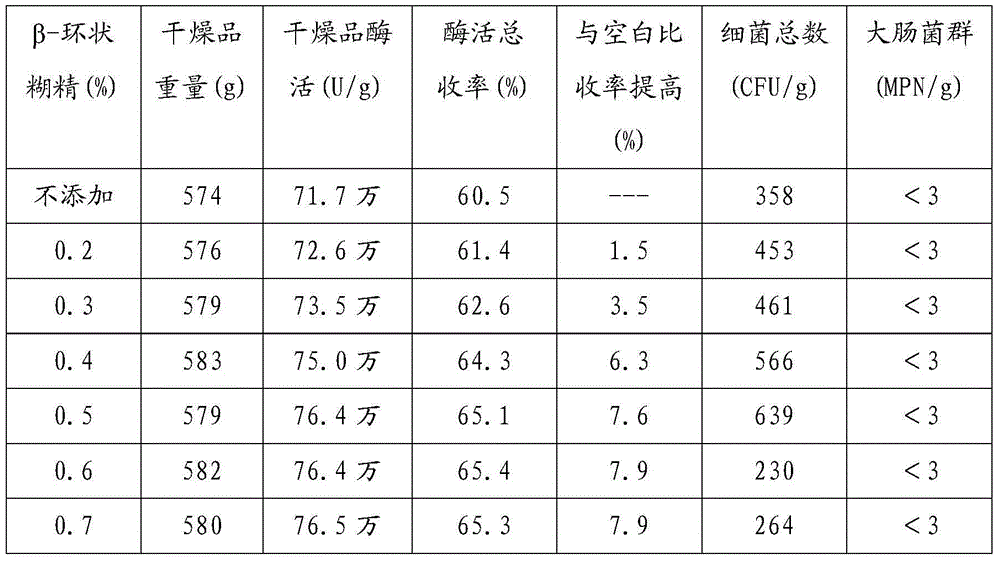

Image

Examples

Embodiment 1

[0025] A method for purifying food-grade neutral protease, comprising the steps of:

[0026] 1) Use Bacillus subtilis AS1.398 strains for fermentation, the fermenter is 1000L, take out 600kg of fermented liquid, and detect the enzyme activity of the fermented liquid to be 6800U / g to obtain the neutral protease fermented liquid; then add flocculant to the fermented liquid , stir evenly, and let it stand for 30 minutes to make the impurities and flocculant combine into a mass; it is beneficial to filtration; the flocculant is anionic polyacrylamide; Dissolve in water to obtain pre-dissolved flocculant, and then add the pre-dissolved flocculant to the neutral protease fermentation broth in a ratio of 1:100 by weight, that is, add 6kg of pre-dissolved flocculant to 600kg neutral protease fermentation broth In, stir slowly for 10 minutes.

[0027] 2) Plate and frame filtration: The neutral protease fermentation liquid after the flocculation reaction is completed is subjected to pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com