A temperature stress automatic release device for a new rail to be replaced and its application method

A technology of temperature stress and new rails, applied in the field of transportation, can solve the problems of restricting the efficiency of overhaul rail replacement, harsh working environment, and high labor intensity, and achieve the effects of convenient and flexible assembly and disassembly, filling technical gaps, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

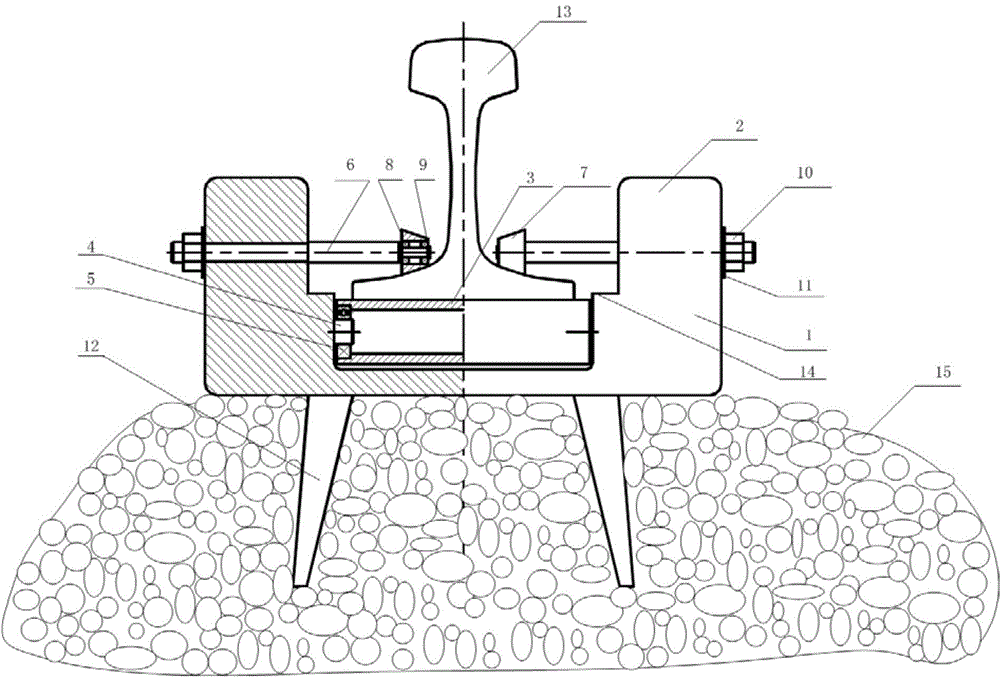

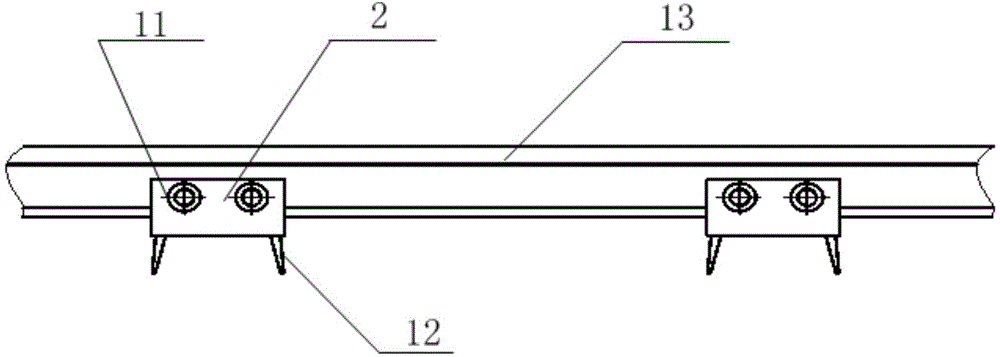

[0019] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

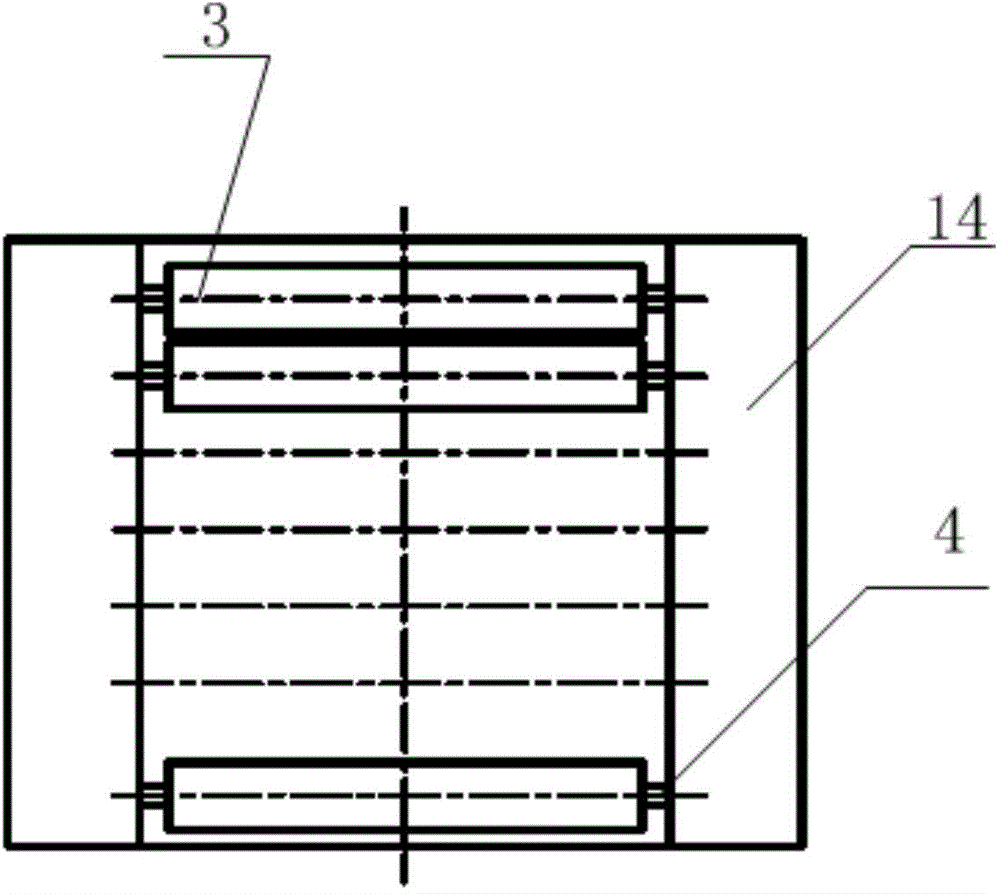

[0020] see Figure 1-3 , the present invention includes: a U-shaped support 1, a U-shaped arm is arranged on the U-shaped support 1, and the U-shaped arm is divided into an upper structure 2 and a lower structure 14, and the lower structure 14 is larger than the upper structure 2 Slightly thicker to form a convex platform; the middle of the U-shaped arm substructure 14 is provided with a cylindrical roller system (see figure 2 ), the cylindrical roller system is composed of several cylindrical rollers 3, several short shafts 4 and several rolling ball bearings 5.

[0021] The short shaft 4 is respectively inlaid on both sides of the lower structure 14 of the U-shaped arm, and the short shaft 4 is connected with the cylindrical roller 3 with a rolling ball bearing 5; the upper limit of the cylindrical roller system is lower than that of the U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com