Magnetic drive submerged pump

A magnetic drive, submerged pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of assembly and maintenance difficulties, safety accidents, complex structures, etc., and achieve simple and convenient assembly and maintenance, improved safety, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

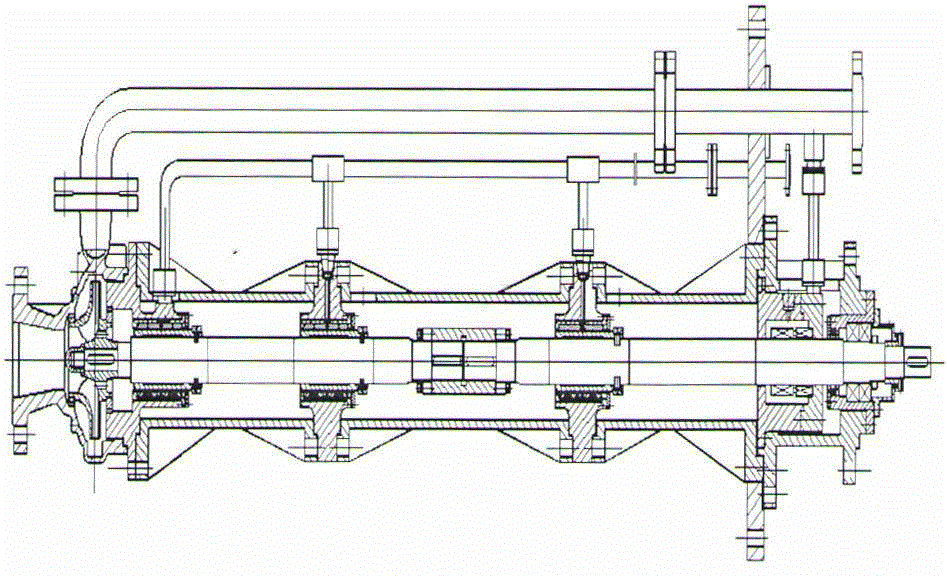

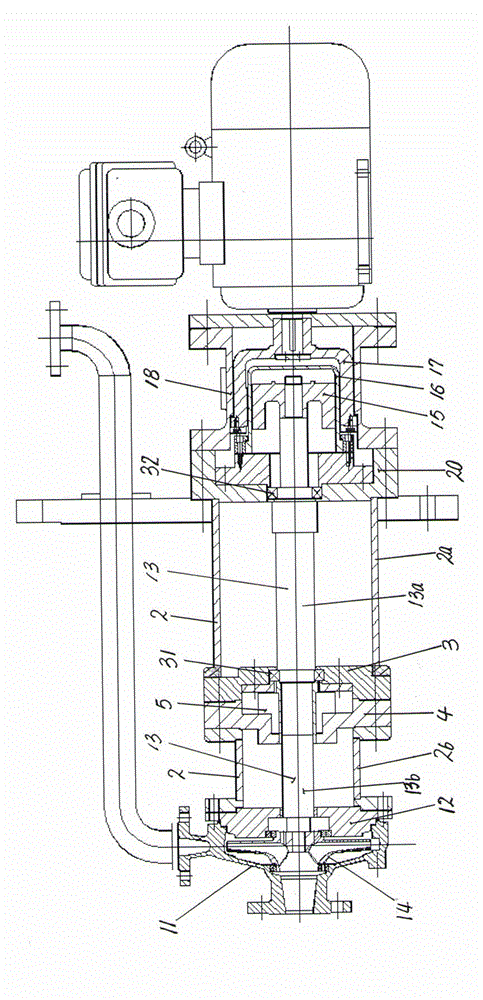

[0011] The magnetic drive submerged pump of the present invention consists of a pump body 11, a pump cover 12, a pump shaft 13, an impeller 14, a shaft frame tube 2, bearing devices 31, 32 installed between the shaft frame tube 2 and the pump shaft 13, and a mechanical seal device. 5. The inner magnetic rotor 15, the spacer sleeve 16, the outer magnetic rotor 17, the connecting frame 18 and the bearing box are composed. The axle frame tube 2 is composed of two sections of tube tubes 2a and 2b butted, and the pump shaft 13 can be composed of two sections of the pump shaft 13a , 13b are formed by the butt joint of the shaft coupling, and the bearing base plate 3 and the sealing gland 4 are fixedly connected between the two ends of the tube tubes 2a and 2b, and the sealed grease-lubricated rolling bearing 31 is arranged between the bearing base plate 3 and the pump shaft 13b. A mechanical seal device 5 is provided on the pump shaft 13b between the bearing seat plate 3 and the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com