Permanent magnet motor rotor with direct-axis inductance larger than quadrature-axis inductance

A quadrature-axis inductance, permanent magnet motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of permanent magnet loss of magnetism, increased motor cost, limited motor performance, etc. Magnetic effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

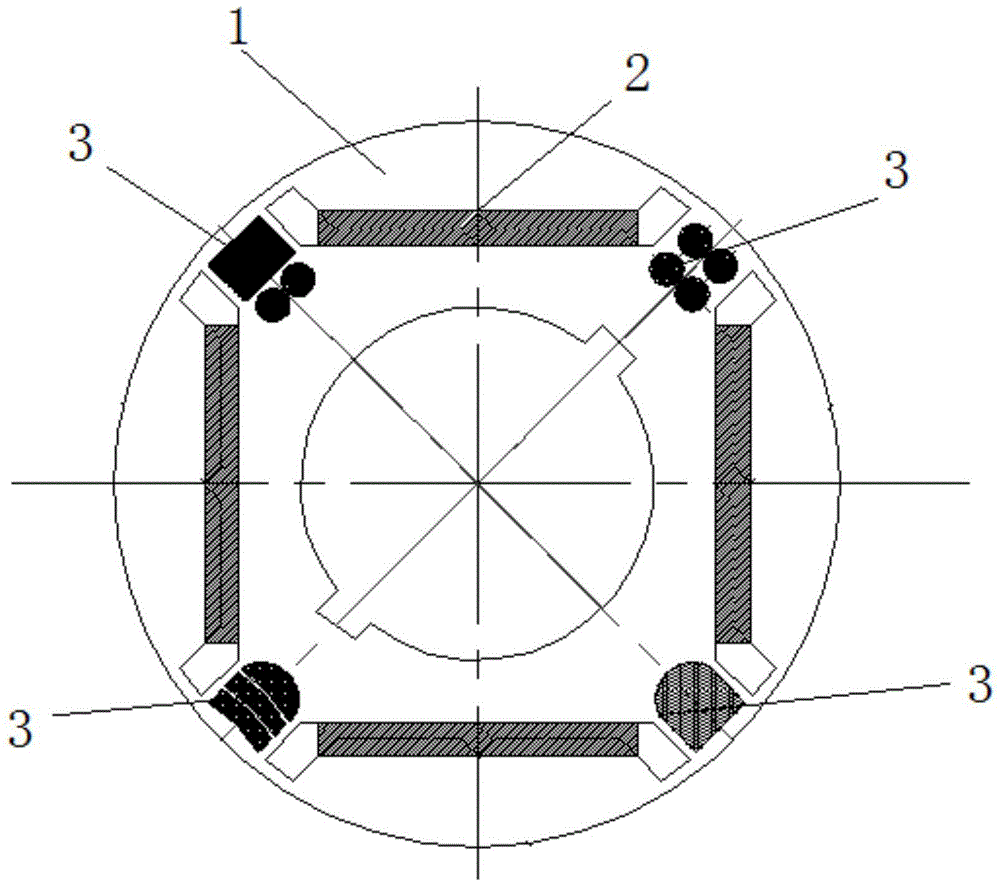

[0043] Such as figure 1 As shown, a permanent magnet motor rotor whose direct axis inductance is greater than the quadrature axis inductance includes a rotor core 1 composed of rotor punches, a permanent magnet 2 and a flux barrier 3; wherein the permanent magnet 2 is arranged on the rotor core 1 Inside, they are evenly distributed along the circumference of the rotor core 1 , and magnetic flux barriers 3 are set on the quadrature axis magnetic path between adjacent permanent magnets 2 .

[0044] The shape of the flux barrier 3 includes, but not limited to, one or a combination of circular hole, rectangle, arc, fan, and triangle.

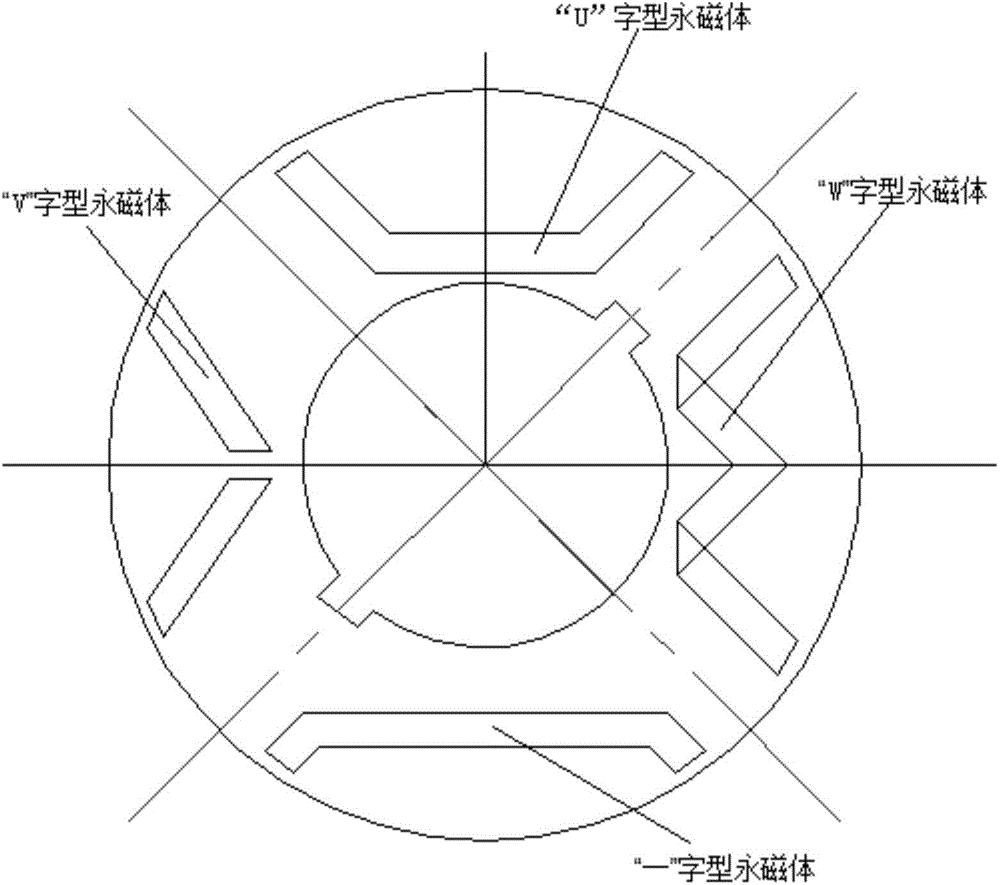

[0045] The shape of the permanent magnet 2 includes but not limited to "U", "V", "W", "one" and rectangular shape.

[0046] Working principle of the present invention is:

[0047] The electromagnetic torque equation of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com