Neutral point potential balancing control system and method of three-level inverter

A technology of three-level inverter and potential balance, which is applied in the direction of control/regulation system, regulation of electrical variables, instruments, etc. It can solve problems such as fast dynamic response, increased hardware investment, unbalanced capacitor voltage, etc., to improve system performance , Improve the system response ability, reduce or suppress the effect of fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

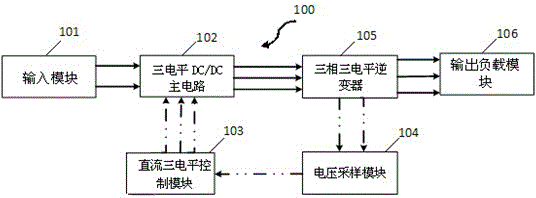

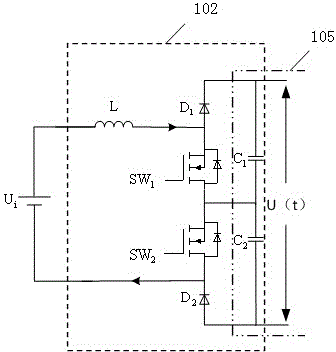

[0022] Such as figure 1 A schematic diagram of the connection of functional modules of a three-level inverter based on three-level DC / DC is shown, and a midpoint potential balance control system 100 of a three-level inverter includes: an input module 101, a three-level DC / DC main Circuit 102 , DC three-level control module 103 , voltage sampling module 104 , three-phase three-level inverter 105 , and output load module 106 .

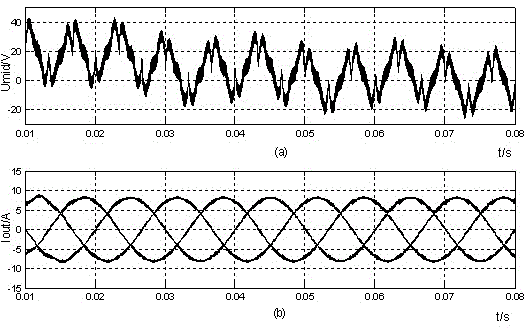

[0023] The system collects the DC bus voltage of the three-phase three-level inverter 105 and the midpoint voltage of the two capacitors on the DC side in real time through the voltage sampling module 104, and sends them to the DC three-level control module 103 to generate corresponding control quantities; according to the obtained control quantities Determine the working mode of the system and the corresponding switching state of the switching tube, and at the same time meet the constraints of the midpoint potential determined by the ratio of the off t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com