Mixing attenuation control circuit in motor drive chip

A motor drive chip, attenuation control technology, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of increasing the difficulty and cost of PCB design, reduce design cost, reduce design difficulty, reduce Effect of Peripheral Resistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment implements under the premise of the technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to the following the embodiment.

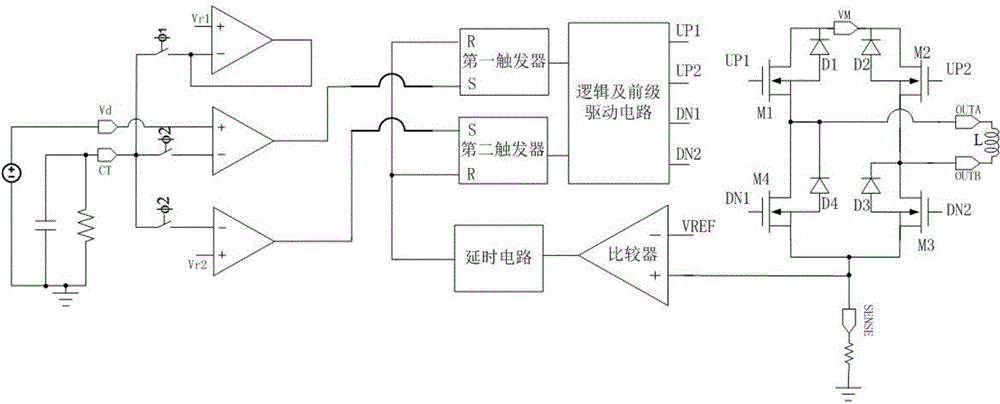

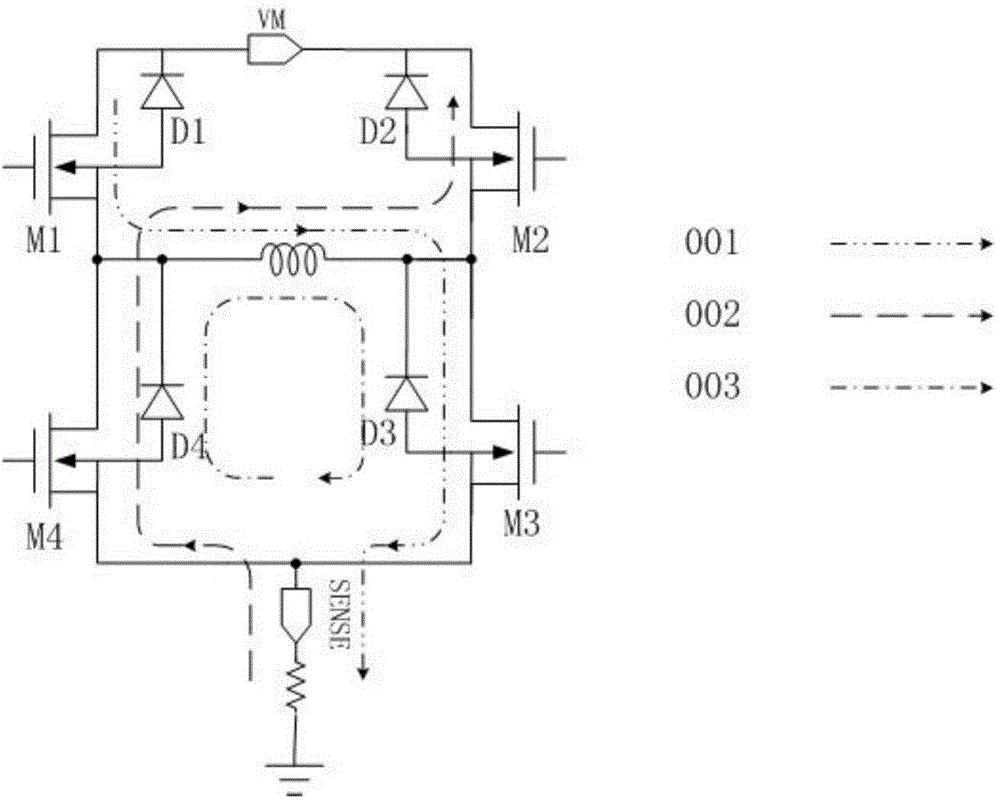

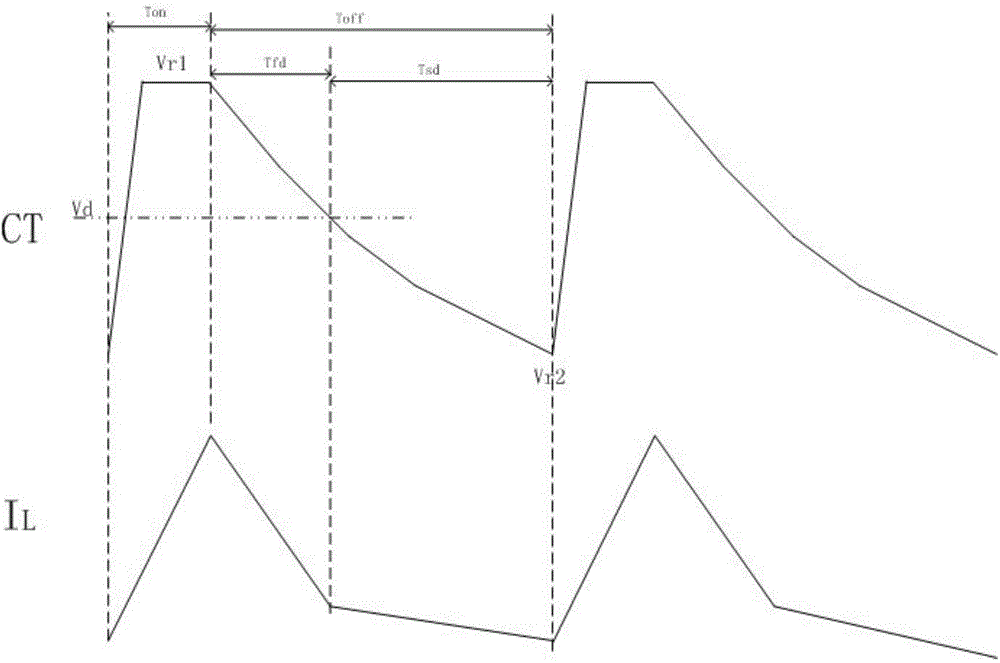

[0030] A mixed attenuation control circuit for a motor drive chip of the present invention includes an oscillator, a counter, a comparator, a first flip-flop, a second flip-flop, a logic and a pre-stage drive circuit, a current detection circuit, an H-bridge output stage, and an inductive load. The inductive load is connected to the output terminals OUTA and OUTB of the H-bridge output stage; the node A between the two symmetrical power devices of the H-bridge output stage is respectively connected to the current detection circuit and the first input terminal of the comparator; the first input terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com