Separation bed for differential type pneumatic dry separator, dry separator main machine and complete device

A differential and sorting technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of limited scale expansion, high requirements for particle size, moisture, and low investment. , to achieve high transmission efficiency, long wear life and good antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

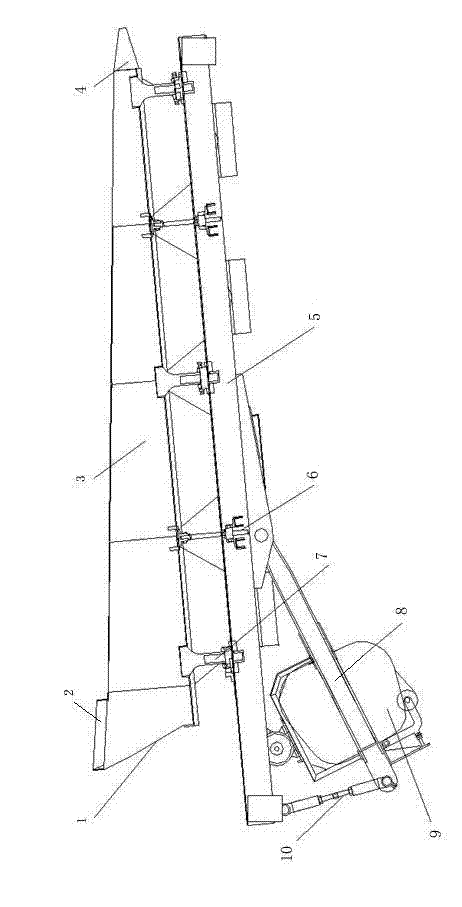

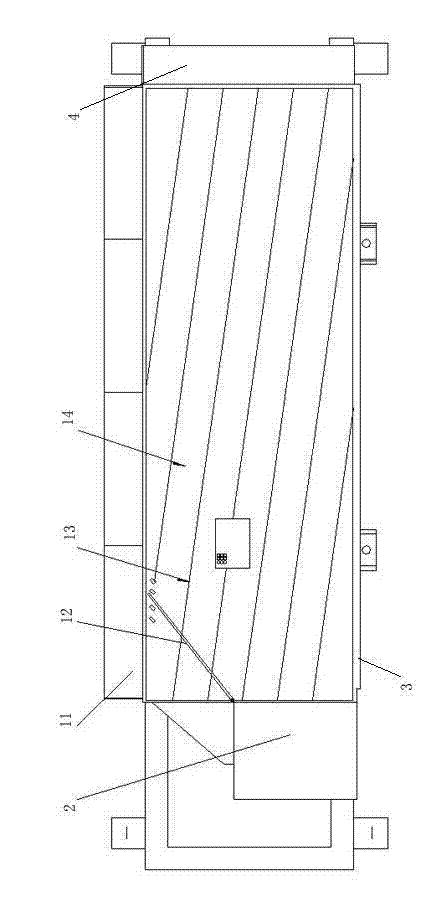

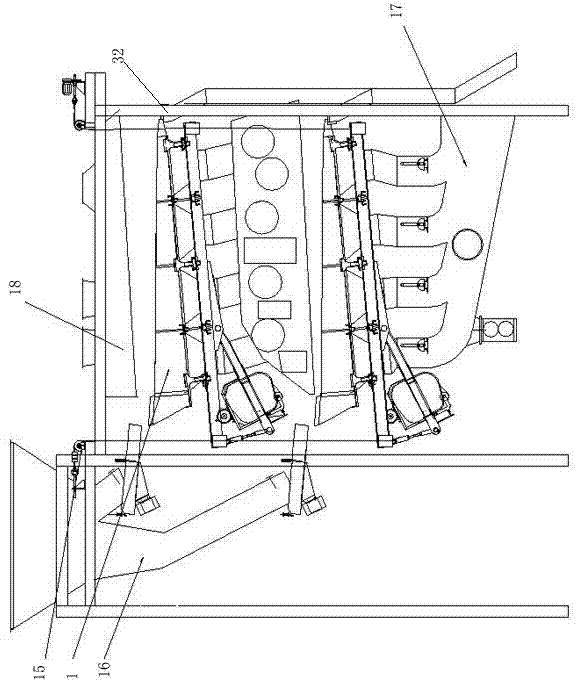

[0034] The sorting bed for this kind of differential air dry separation machine disclosed in the present invention comprises a rectangular sorting bed box 1, and the sorting bed box 1 is connected with the transmission frame 5 through an adjustment connecting device, and one end of the transmission frame is The bottom of the vibrator 9 is equipped with. The two ends of the sorting bed are the feed port 2 and the discharge port 4 respectively, and the discharge port is the discharge port for heavy materials; the discharge baffle 11 and the back plate 3 respectively constitute the two long sides of the rectangular box, and the discharge port The baffles 11 are respectively the baffles on the light material discharge port and the intermediate material discharge port. The bottom surface of the sorting bed box is composed of multiple rectangular sawtooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com