Numerical control buoy forming machine

A molding machine and buoy technology, applied in automatic control devices, shearing machine control devices, metal processing machinery parts, etc., can solve the problems of troublesome replacement of molds, large errors, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

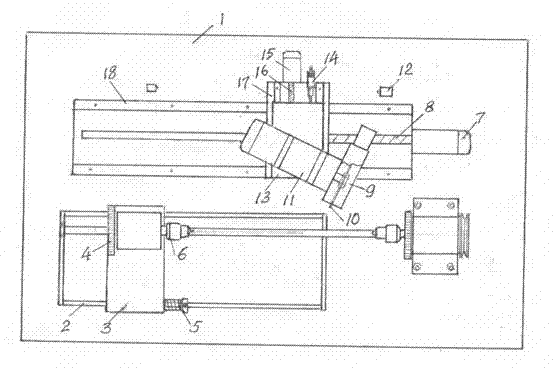

[0016] Such as figure 1 As shown, the present invention includes a machine base 1, a blank rotating device guide rail seat 2, a blank chuck seat 3, a transmission gear 4, a positioning sleeve 5, a chuck 6, a transverse motor 7, a transverse screw rod 8, a dust cover 9, a saw Sheet 10, main motor 11, limit switch 12, longitudinal guide rail seat 13, fine-tuning device 14, longitudinal motor 15, longitudinal screw mandrel 16, longitudinal guide rail 17, transverse guide rail 18 and electronic computer. The invention adopts the numerical control program, utilizes CAD drawing to design the buoy model, and then copies it into the operating system. The operation steps are: turn on the power, start the system, select the stored buoy model file, install the buoy blank on the chuck, start the start and stop button, the main motor and the vertical and horizontal motors run at the same time, control the vertical and horizontal servo motors through the system, press the file model In nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com