'n' shaped element mold for precasting reinforced concrete culvert

A reinforced concrete and mold technology, applied in the direction of mold, mold separation device, etc., can solve the problems of difficulty in formwork installation, concrete grout leakage, and affecting the construction quality of culverts and tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

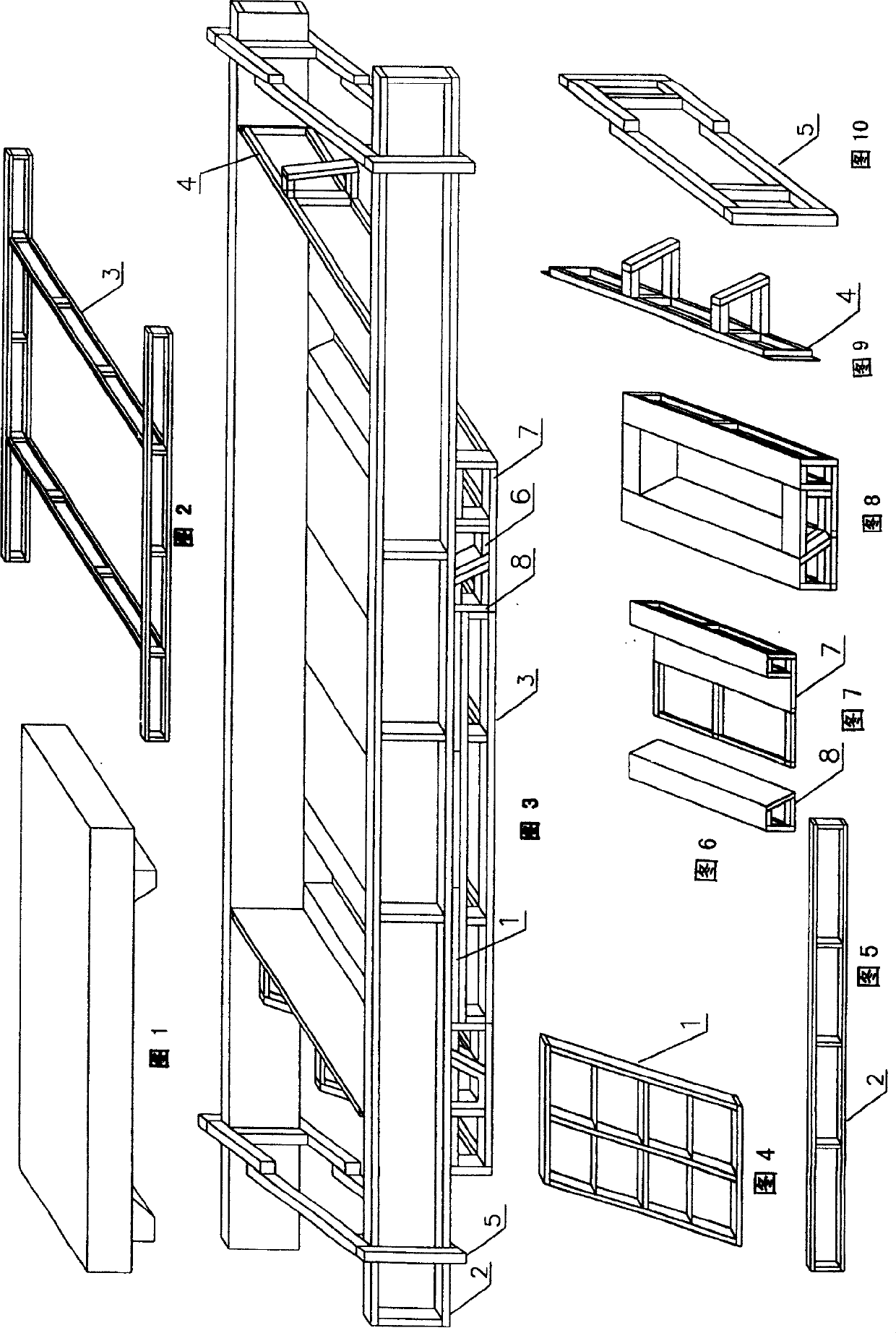

[0018] of the present invention Molds for shaped components. It is formed by the combination of side form 2, side form 4 with support and side plate fixing frame 5 Plate side molds. Blocking mold 6, chair-shaped bottom mold 7, trapezoidal bottom mold 8, bottom plate 1, and support frame 3 form the bottom support formwork system, which is installed below the mold frame template, and side mold 4 is fixed on the chair-shaped bottom mold 7 by bolts. The side molds together with the bottom support formwork system constitute the production A complete set of molds for the shape plate (as shown in Figure 3). The base plate 1 is a similar "Tian"-shaped skeleton welded by square steel pipes, and flat steel can be added to the skeleton, and a steel plate is welded on one side of the skeleton, and holes are drilled in its proper position so that the bolts are connected with the side form. Side form 2 is the skeleton similar to " day " " mesh " font that is welded into by square ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com