Universal tool capable of quickly disassembling various components

A technology for general tools and parts, applied in the field of maintenance tools, can solve the problems of high cost of dismantling brackets, difficult selection and use, inability to use, etc., and achieves the effect of reducing labor intensity of workers, reducing maintenance workload, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

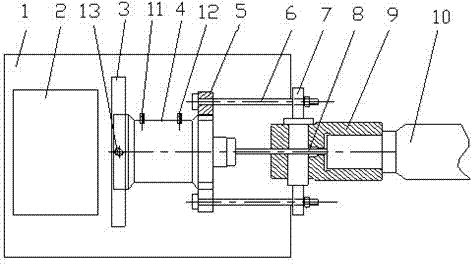

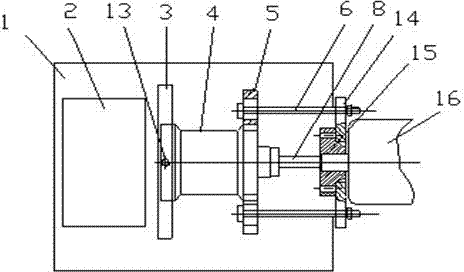

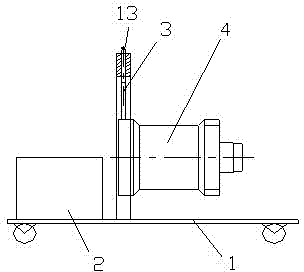

[0021] The invention is a general tool for dismantling various mechanical components, which can directly disassemble various components such as work roll yokes, motor adapters, journal gears and the like of a straightening machine.

[0022] The present invention is made up of three parts of moving trolley 1, hydraulic drive device, dismantling device.

[0023] The hydraulic driving device is fixed on the moving trolley 1, and the dismantling device is connected with the hydraulic driving device. The hydraulic driving device drives the dismantling device to dismantle various parts such as the work roll fork 9, the motor adapter 15, and the journal gear, and the mobile trolley 1 The hydraulic driving device and the dismantling device can be moved to correspond to a plurality of disassembled parts in different positions.

[0024] As shown in the figure, the hydraulic drive device includes a hydraulic pump station 2, a hydraulic cylinder height adjustment bracket 3, and a hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com