Automatic double-track screen printing device transmitted through connecting rods

A technology of screen printing and connecting rod transmission, which is applied to screen printing machines, printing machines, printing machines, etc., and can solve problems such as inaccurate positioning of platen transmission, inaccurate color registration of screen printing, and complicated platen connection mechanisms, etc. Achieve the effect of good connecting rod rigidity, high printing precision and low movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

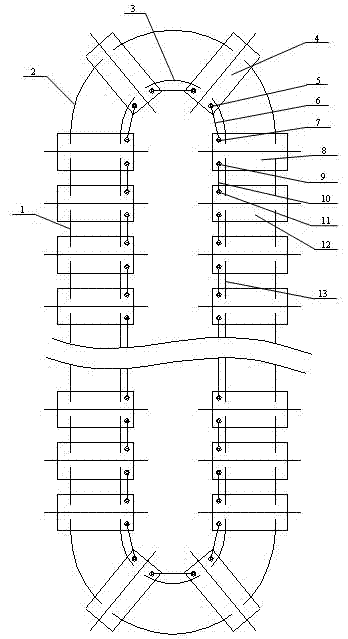

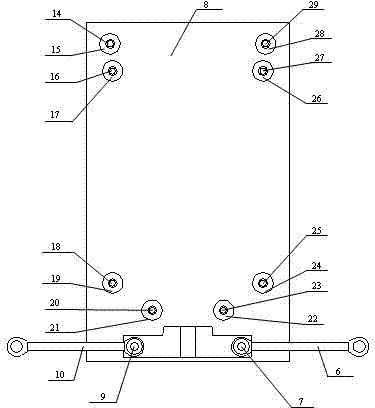

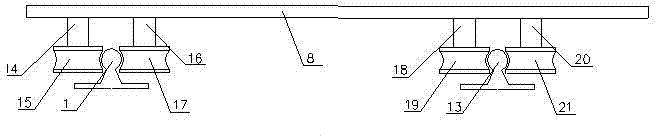

[0012] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, see Figure 1 to Figure 3 :

[0013] The dual-track automatic screen printing device with connecting rod transmission implemented according to the scheme of the present invention includes a printing platen for placing the substrate and driving it to advance at each station. In order to overcome the unstable movement caused by the traditional single track, the present invention The track of the embodiment adopts an inner and outer double track structure arranged at equal intervals. The double track consists of an inner track and an outer track, and the inner track includes an arc inner track with two semicircles. The outer orbit is an arc outer orbit with semicircles at both ends.

[0014] Bearing transmission is adopted between the printing platen and the double track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com