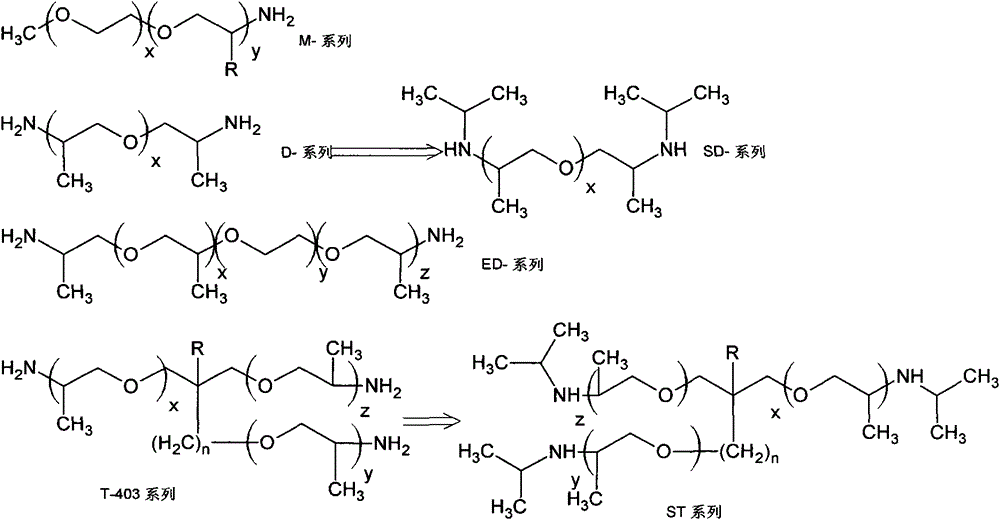

A kind of preparation method of bis (fatty alcohol polyoxyalkylene ether) secondary amine

A technology of alcohol polyoxyalkylene alkenyl ether and alcohol polyoxyalkylene, which is applied in the field of preparation of bis-secondary amines, can solve the problems of inability to prepare secondary amine content and lack, etc., achieve less side reactions, convenient feeding, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

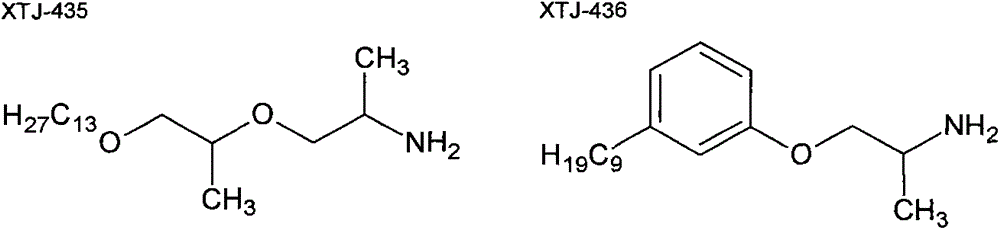

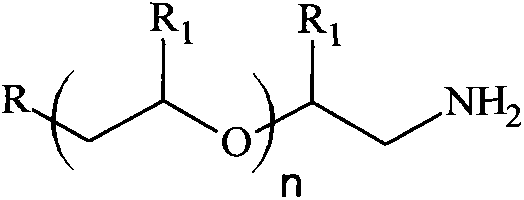

Method used

Image

Examples

example 1

[0047] 500g terminal primary amino C 12~14 Alcohol polyoxyethylene ether, 15g of catalyst Raney nickel are added to a 1000ml four-necked flask with a stirrer, a thermometer, a gas conduit, and a straight condenser tube, and the terminal primary amino group C 12~14 The molecular weight of alcohol polyoxyethylene ether is 390, and the amination rate is 46%. Pass hydrogen gas at a flow rate of 100ml / min, raise the temperature to 200°C at a stirring speed of 300r / min, and react for 5h.

[0048] After the reaction is over, lower the temperature to below 100°C, stop the hydrogen flow, and remove the catalyst, that is, bis(C 12~14 Alcohol polyoxyethylene) secondary amine, the secondary amine content (S%) is 92%.

example 2

[0050] 200g terminal primary amino C 12~14 Alcohol polyoxyethylene ether, 10g of catalyst Raney nickel are added to a 500ml four-necked flask with a stirrer, a thermometer, a gas conduit, and a straight condenser tube, and the terminal primary amino group C 12~14 The molecular weight of the alcohol polyoxyethylene ether is 390, and the amination rate is 63%. Pass hydrogen gas at a flow rate of 100ml / min, raise the temperature to 200°C at a stirring speed of 300r / min, and react for 5h.

[0051] After the reaction is over, lower the temperature to below 100°C, stop the hydrogen flow, and remove the catalyst, that is, bis(C 12~14 Alcohol polyoxyethylene) secondary amine, the secondary amine content (S%) is 89%.

example 3

[0053] 400g terminal primary amino C 12~14 Alcohol polyoxypropylene ether, 20g catalyst Raney nickel joins in the 1000ml four-necked flask that has stirrer, thermometer, gas conduit, straight condenser tube, terminal primary amino group C 12~14 The molecular weight of the alcohol polyoxypropylene ether is 476, and the amination rate is 61%. Pass hydrogen gas at a flow rate of 200ml / min, raise the temperature to 200°C at a stirring speed of 300r / min, and react for 5h.

[0054] After the reaction is over, lower the temperature to below 100°C, stop the hydrogen flow, and remove the catalyst, that is, bis(C 12~14 Alcohol polyoxypropylene) secondary amine, the secondary amine content (S%) is 43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com