Anti-spalling primer

An anti-peeling and primer technology, applied in the direction of coating, etc., can solve the problems of inapplicability, increased coating of accessories, weak adhesion, etc., achieve good cooking resistance and resistance to alternating cold and heat, reduce waste and Trouble, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

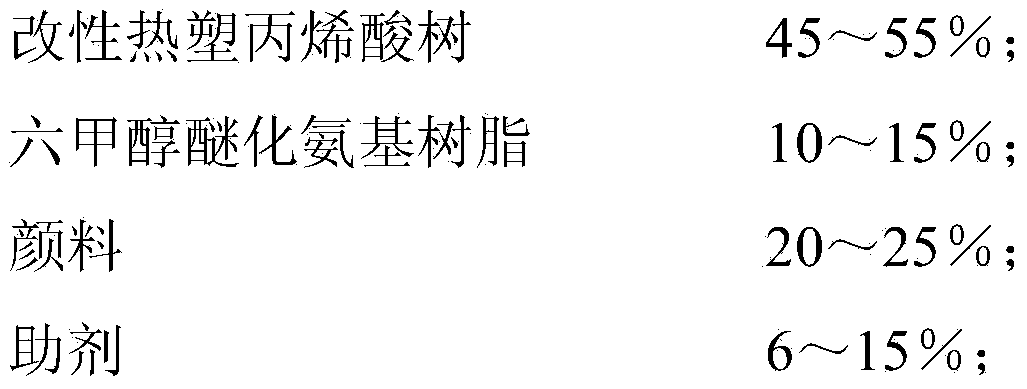

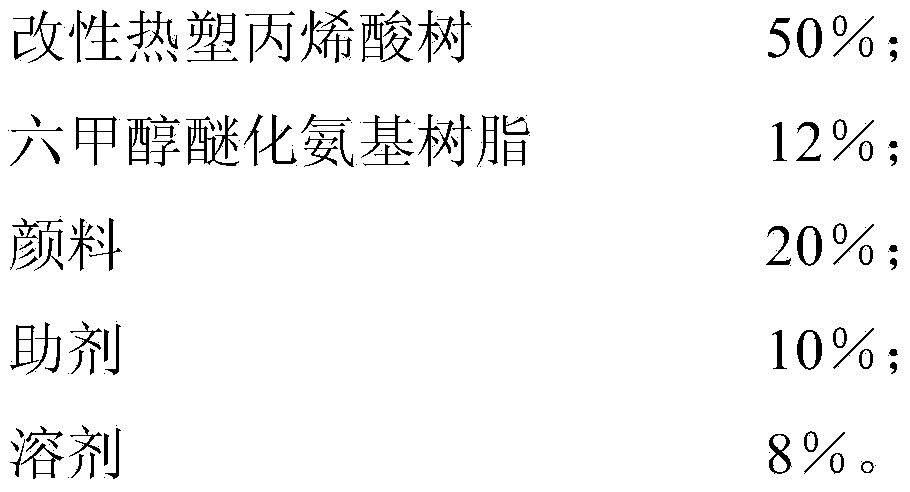

[0015] The following is a list of the components and weight percentages of an anti-stripping primer of the present invention:

[0016] When preparing, weigh the raw materials according to the proportion, first add the modified thermoplastic acrylic resin to the dispersant and stir evenly, add the pigment and solvent while stirring, disperse and grind until the fineness is less than 20 microns, and then add the flow after cooling. For leveling agent, just stir evenly.

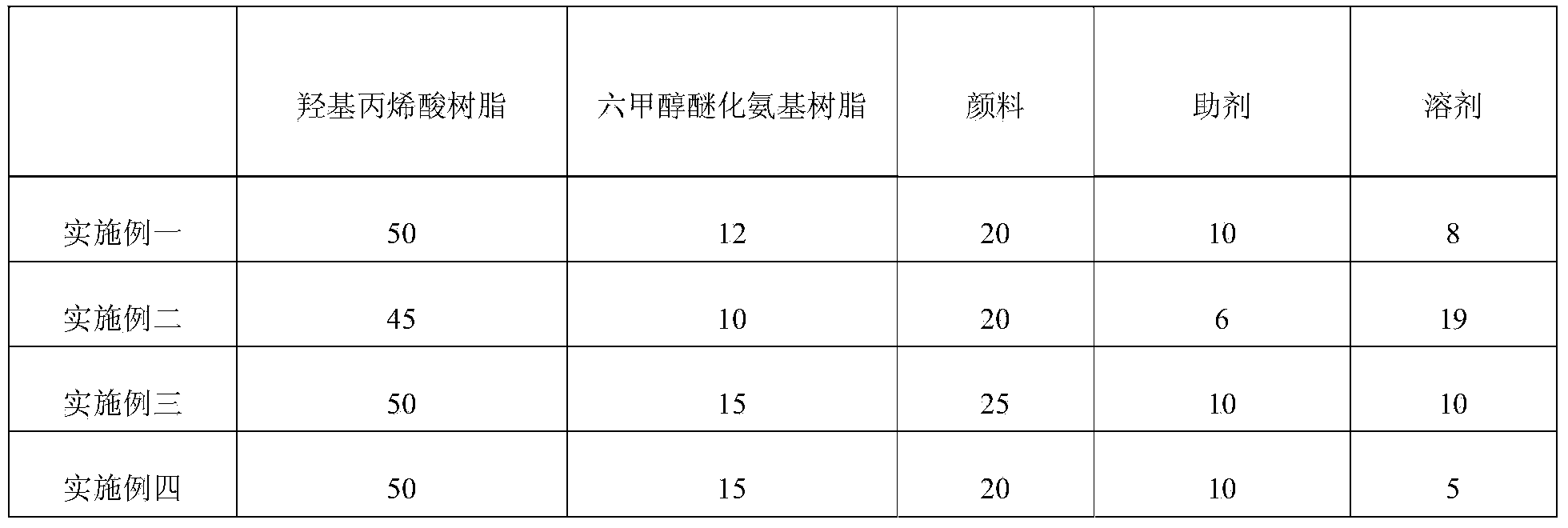

[0017] Table 1 Composition and content table

[0018]

[0019] Among them, the properties of the product prepared according to Example 1 are as follows:

[0020] Viscosity s

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com