Alkaline cleaning additive used after acid texturing of polycrystalline silicon wafers, and using method thereof

A polycrystalline silicon wafer, alkali cleaning technology, applied in the directions of detergent compositions, detergent compounding agents, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An alkali cleaning additive for acid texturing of polycrystalline silicon wafers and a method of use thereof, the process steps are as follows:

[0025] 1) Prepare alkaline cleaning additives: Add 0.1g of Span-80, 0.6g of Tween-40, and 0.3g of lauryl polyethylene glycol ether into deionized water to obtain 100g of alkaline cleaning additive solution.

[0026] 2) Prepare alkaline cleaning solution: dissolve 1.5kg of NaOH in deionized water to obtain 50kg of alkaline solution; dissolve 100g of alkaline cleaning additive prepared in step 1) in the alkaline solution to obtain alkaline cleaning solution.

[0027] 3) Alkali cleaning: immerse the acid-textured polysilicon wafer in the alkali cleaning solution prepared in step 2) for surface alkali cleaning, the temperature of the alkali cleaning is 25° C., and the time of alkali cleaning is 25 s.

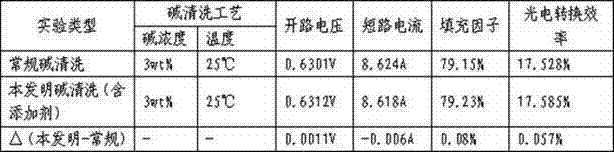

[0028] After conventional cleaning and cleaning after adding the alkaline cleaning additive of the present invention, the efficien...

Embodiment 2

[0033] An alkali cleaning additive for acid texturing of polycrystalline silicon wafers and a method of use thereof, the process steps are as follows:

[0034] 1) Prepare alkaline cleaning additives: add 0.5g of Span-80, 2.5g of Tween-40, and 1.5g of lauryl polyethylene glycol ether into deionized water to obtain 100g of alkaline cleaning additive solution.

[0035] 2) Prepare alkaline cleaning solution: dissolve 0.5kg of NaOH in deionized water to obtain 5kg of alkaline solution; dissolve 100g of alkaline cleaning additive prepared in step 1) in the alkaline solution to obtain alkaline cleaning solution.

[0036] 3) Alkali cleaning: immerse the acid-textured polysilicon wafer in the alkali cleaning solution prepared in step 2) to perform surface alkali cleaning, the temperature of the alkali cleaning is 45° C., and the alkali cleaning time is 10 s.

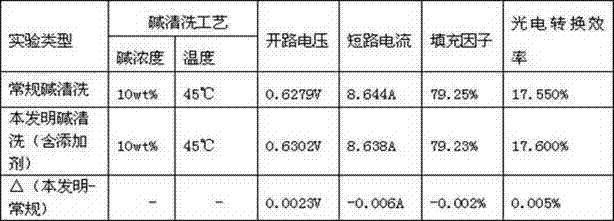

[0037] After conventional cleaning and cleaning after adding the alkaline cleaning additive of the present invention, the effec...

Embodiment 3

[0041] An alkali cleaning additive for acid texturing of polycrystalline silicon wafers and a method of use thereof, the process steps are as follows:

[0042] 1) Prepare alkaline cleaning additives: add 0.3g of Span-80, 1.5g of Tween-40, and 1g of lauryl polyethylene glycol ether into deionized water to obtain 100g of alkaline cleaning additive solution.

[0043] 2) Prepare alkaline cleaning solution: dissolve 1kg of NaOH in deionized water to obtain 20kg of alkaline solution; dissolve 100g of alkaline cleaning additive prepared in step 1) into the alkaline solution to obtain alkaline cleaning solution.

[0044] 3) Alkali cleaning: immerse the acid-textured polysilicon wafer in the alkali cleaning solution prepared in step 2) to perform surface alkali cleaning, the temperature of the alkali cleaning is 30° C., and the alkali cleaning time is 18 s.

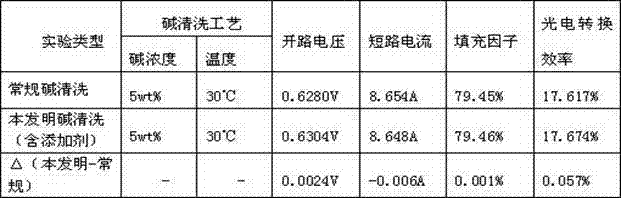

[0045] After conventional cleaning and cleaning after adding the alkaline cleaning additive of the present invention, the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com