Intake manifold integrating oil-gas separation device with PCV, engine and automobile

A separation device, intake manifold technology, applied in the direction of engine components, machines/engines, engine lubrication, etc., can solve the problems of insignificant oil and gas separation effect, reduce connection pipelines, etc., so as to improve oil and gas separation efficiency and reduce connection. Pipelines and the effect of reducing the difficulty of engine room layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

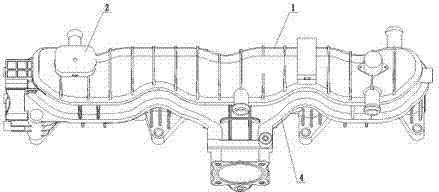

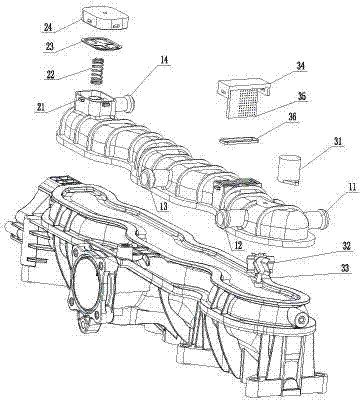

[0044] An intake manifold integrating an oil-gas separation device and a PCV valve, the structure of which is as follows Figure 1-2 As shown, it includes an intake manifold 4, a cover body 1, an oil-gas separation device, and a PCV valve 2.

[0045] The cover body 1 is fixed on one side of the main pipeline of the intake manifold 4 , and the inner cavity of the cover body 1 communicates with the inner cavity of the intake manifold 4 . One side of the cover body 1 is respectively provided with an air inlet pipe 11 , and the other side is provided with a first oil return pipe 12 and a second oil return pipe 13 .

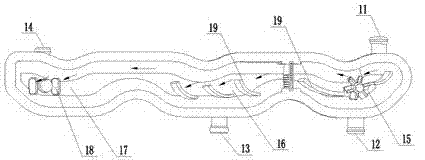

[0046] Such as image 3 As shown, the inner cavity of the cover body 1 is divided into a first chamber 15, a second chamber 16, and a steady flow chamber 17 which are sequentially connected, and their transverse sections are all trapezoidal structures with a large top and a small bottom. The first chamber 15 communicates with the intake pipe 11 and the first oil ret...

Embodiment 2

[0056] An engine, which differs from the prior art only in that the complex of the oil-gas separation device, the PCV valve and the intake manifold is the intake manifold of the integrated oil-gas separation device and the PCV valve provided in Embodiment 1.

[0057] The structure of other parts of this engine is identical with prior art.

Embodiment 3

[0059] A kind of automobile, the difference between this automobile and the prior art only lies in: the structure of its engine is completely the same as that of embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com