Continuous Regenerative Industrial Furnace Waste Heat Utilization System

An industrial furnace, regenerative technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of discontinuous combustion, energy waste, environmental damage, etc., and achieve the effect of improving waste heat utilization efficiency and simplifying pipeline layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

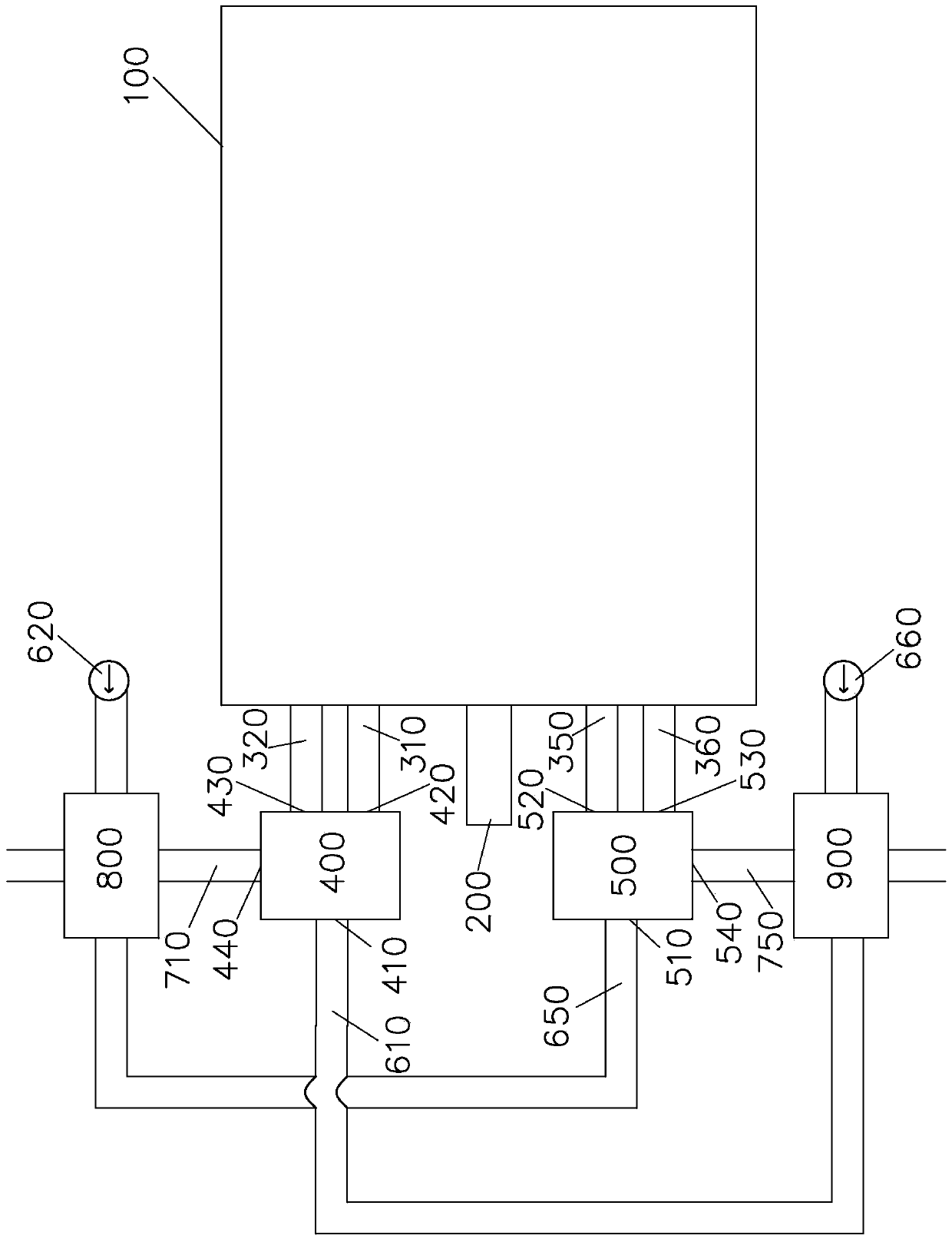

[0027] Please refer to figure 1 , according to an embodiment of the present invention, the continuous regenerative industrial furnace waste heat utilization system includes: a furnace body 100, a fuel nozzle 200, a first ventilation pipe 310, a second ventilation pipe 350, a first smoke exhaust pipe 320, a second The smoke exhaust pipe 360 , the first heat storage 400 , the second heat storage 500 , the first air intake pipe 610 , the second air intake pipe 650 , the first smoke gas passage 710 and the second smoke gas passage 750 .

[0028] The furnace body 100 is provided with a furnace (not shown) for heating materials. The fuel nozzle 200 is arranged on one end wall of the furnace body 100 . The first air pipe 310 , the second air pipe 350 and the fuel nozzle 200 are arranged at equal intervals on the same end wall of the furnace body 100 . The first ventilation pipe 310 and the second ventilation pipe 350 communicate with the furnace gas respectively.

[0029] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com