External valve water cooling system cooling tower of fan motor

A water-cooling system and cooling tower technology, applied in water shower coolers, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of inner wall corrosion, time-consuming and laborious, fan failure, etc., to achieve easy maintenance, tight sealing, and reduce failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

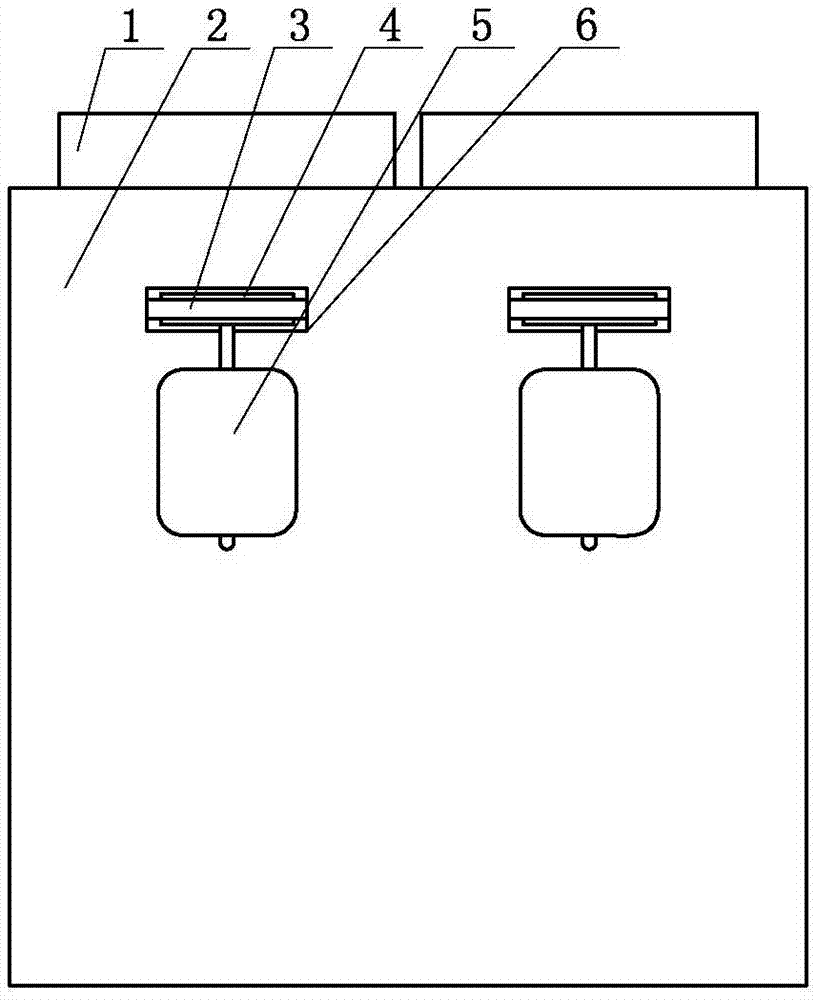

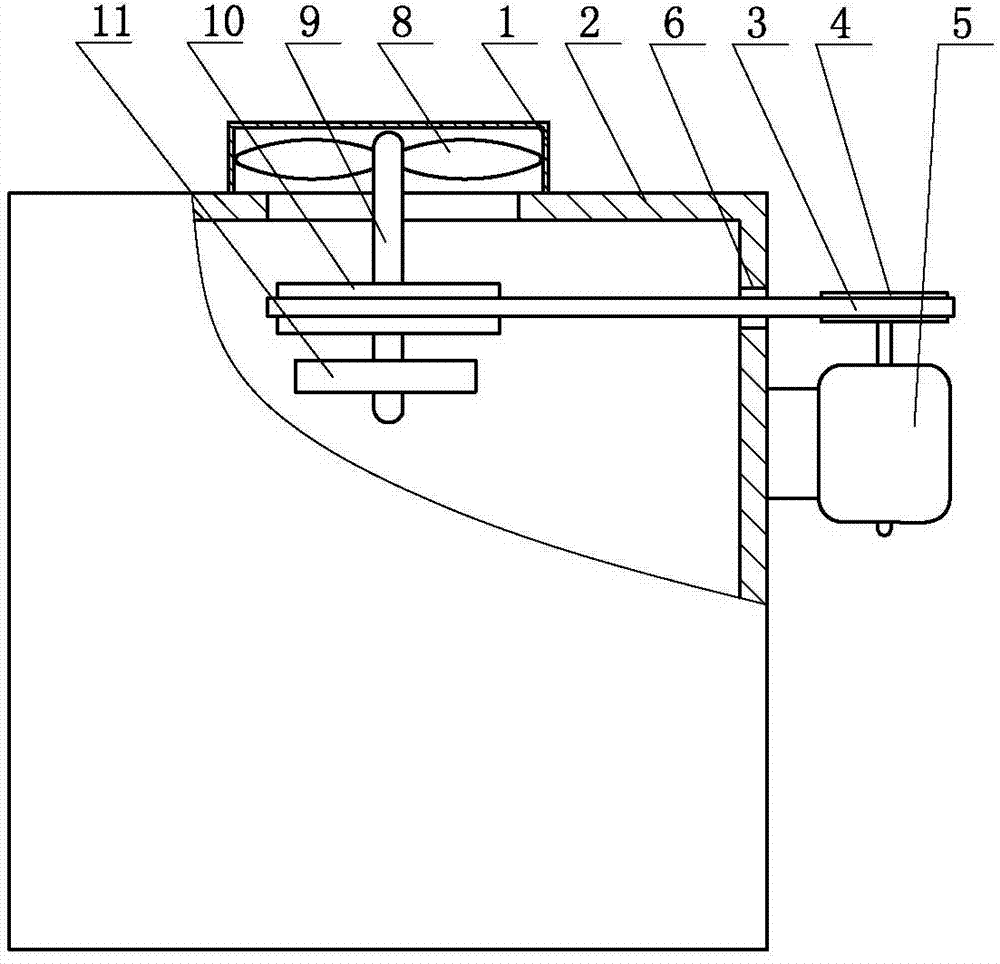

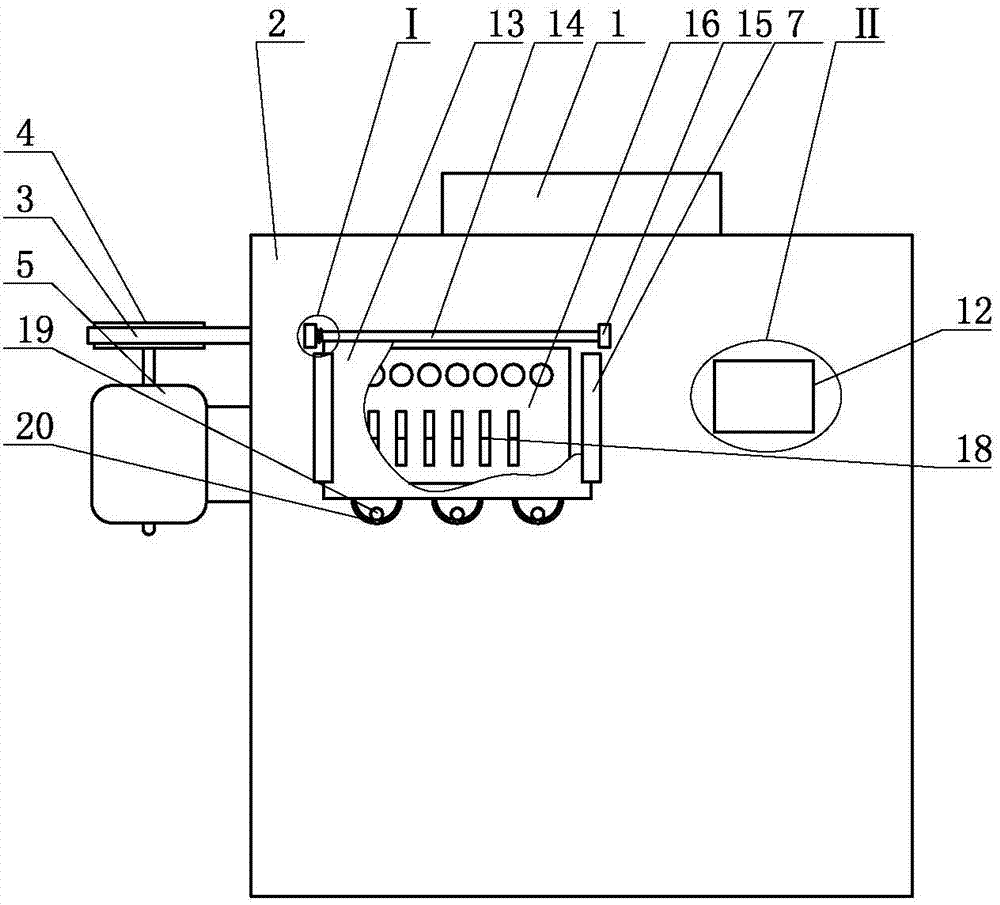

[0016] The cooling tower of the fan motor external valve water cooling system includes a tower body 2, a fan cover 1 is installed on the top of the tower body 2, and a fan 8 is arranged inside the fan cover 1. The outer wall is connected, the second runner 10 is installed on the rotating shaft 9, the motor 5 is installed on the outside of the tower body 2, the first runner 4 is installed on the output shaft of the motor 5, and a through groove 6 is opened on the tower wall of the tower body 2. A belt 3 is set between the wheel 4 and the second runner 10, and the belt 3 passes through the through groove 6; a control groove 16 is provided on the outer wall of the tower body 2, and the control button 18 is arranged in the control groove 16, and the two sides of the control groove 16 top Two fixed disks 15 are arranged on the tower body 2, and a rotating rod 14 is arranged between the two fixed disks 15. The rotating rod 14 rotates relative to the fixed disk 15, and the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com