Flexural rigidity tester for insole backpart

A technology of bending stiffness and tester, which is applied in the direction of testing the strength of materials by applying a stable bending force, which can solve the problems of inconvenient loading and unloading of samples, unstable wearing, low precision, etc., and achieve beautiful appearance, no beating and Vibration phenomenon, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

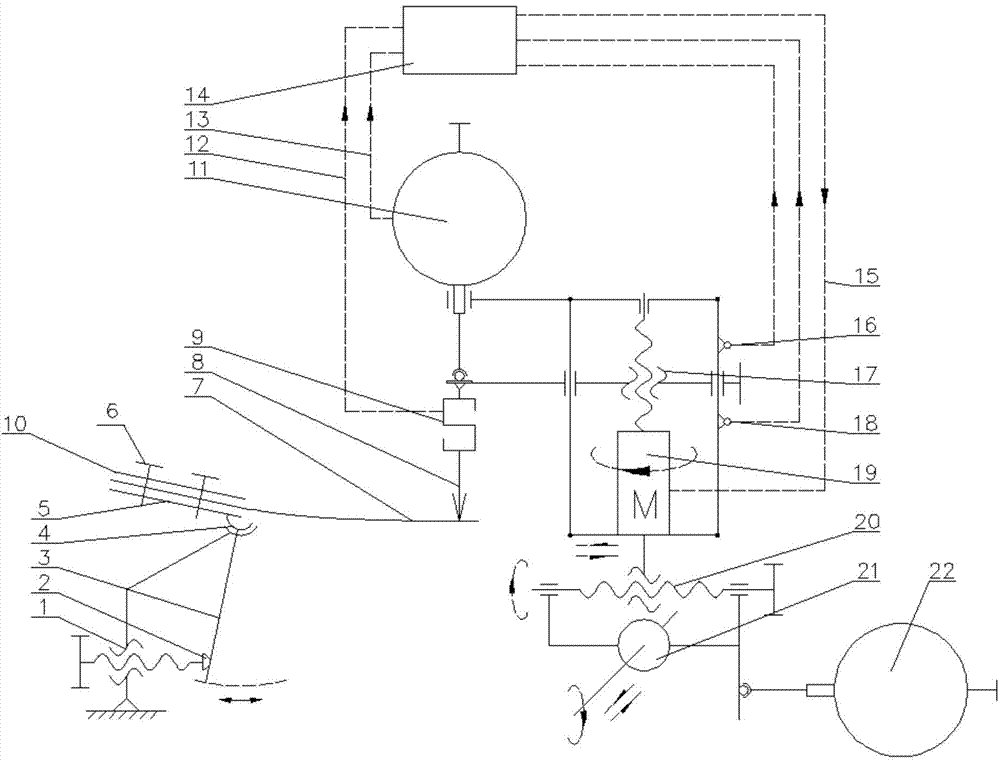

[0020] like figure 1 As shown, the present invention provides a shoe shank bending stiffness tester, including a clamping mechanism for clamping a shank sample 7, a force applying cutter head 8, a force sensor 9, a digital dial indicator 11, Display operation panel 14, upper limit sensor 16, lower limit sensor 18, servo drive motor 19, left and right movement mechanism 20, front and rear movement mechanism 21, dial indicator 22 and controller,

[0021] The force-applying cutter head 8 is connected to the servo drive motor 19 through a screw nut transmission mechanism, and is driven by the servo drive motor 19 to move in a direction close to the shank sample 7 or in a direction away from the shank sample 7;

[0022] The leading screw in the screw nut transmission mechanism is connected with the output shaft of the servo drive motor 19, the nut 17 in the screw nut transmission mechanism is connected with the force applying cutter head 8, and the upper and lower sides of the nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com