On-line gas density measuring method

A gas density and measurement method technology, applied in the field of measurement, can solve the problems of restricting the promotion and application of metering devices, high manufacturing costs and maintenance costs of metering devices, etc., and achieve the effect of accurate and reliable measurement structure, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] one. measuring device

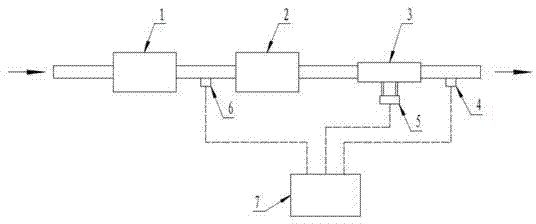

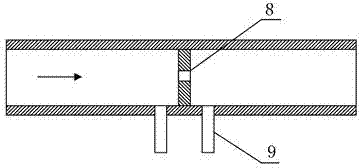

[0021] see figure 1 , the measuring device used in the present invention mainly includes a flow regulator 2, a flow restrictor 3, a differential pressure sensor 5 and a computer 7. In communication, the two air pressure input interfaces of the differential pressure sensor 5 are respectively connected to the pressure-taking tubes 9 on both sides of the orifice 8 of the restrictor 3 , and the signal output terminal thereof is connected to the input port of the computer 7 .

[0022] A temperature sensor 4 is installed on the outlet side of the throttle valve 3 , and its signal output terminal is connected to the input port of the computer 7 . A pressure reducing valve 1 is arranged at the inlet end of the current regulator 2, a gas pressure sensor 6 is arranged on the pipeline between the pressure reducing valve 1 and the current regulator 2, and the signal output terminal of the gas pressure sensor 6 is connected to the input of the computer 7 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com