An electrical connector applied to a modular lighting device

A technology of electrical connectors and lighting devices, which is applied to the components of lighting devices, lighting devices, and connections. The effect of simple method and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

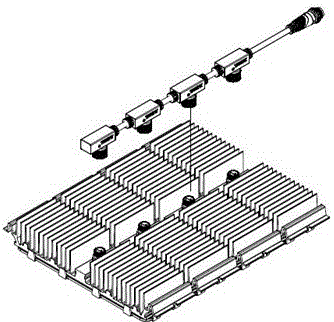

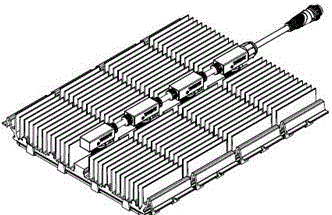

[0048] This embodiment provides an electrical connector applied to a modular lighting device. The modular lighting device includes at least one module, wherein the electrical connector includes a connector assembly, at least one male connector disposed on the module And / or female connector, the connector assembly is provided with at least one male connector and / or female connector, no exposed connecting wire is provided between the connector on the module and the module, the connector on the module Cooperate and connect with at least one connector on the connector assembly.

[0049] In the electrical connector applied to the modular lighting device provided by this embodiment, there is no exposed connecting wire between the connector on the module and the module, which solves the problem of the connection between the connector and the module. The problem of messy wiring between them is eliminated, and the connection between the connector and the module is more neat.

[0050] ...

Embodiment 2

[0059] This embodiment provides an electrical connector applied to a modular lighting device. The modular lighting device includes at least one module, wherein the electrical connector includes a connector assembly, at least one male connector disposed on the module And / or female connector, the connector assembly is provided with at least one male connector and / or female connector, no exposed connecting wire is provided between the connector on the module and the module, the connector on the module Cooperate with at least one connector on the connector assembly;

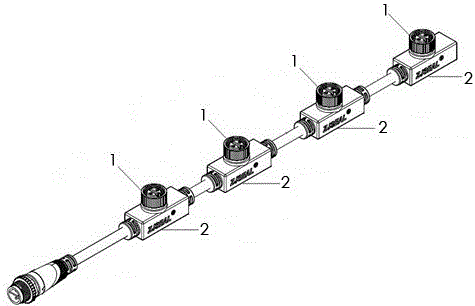

[0060] The male connectors and / or female connectors provided on the connector assembly provided in this embodiment are connected in parallel or in series or in parallel with each other, and the connectors on the connector assembly are flexibly connected.

[0061] Such as image 3 As shown, the wires wrapped by the soft insulating layer between adjacent female connectors 1 are connected in parallel or in series. Fi...

Embodiment 3

[0066] This embodiment provides an electrical connector applied to a modular lighting device. The modular lighting device includes at least one module, wherein the electrical connector includes a connector assembly, at least one male connector disposed on the module And / or female connector, the connector assembly is provided with at least one male connector and / or female connector, no exposed connecting wire is provided between the connector on the module and the module, the connector on the module Cooperate with at least one connector on the connector assembly;

[0067] The set male connectors and / or female connectors can be of two-core structure, four-core structure or six-core structure, that is, the number of connectors connected by the connector assembly and the module is two, four or six. It can be other numbers, and the number set in this embodiment is only a commonly used setting in the implementation of the present invention.

[0068] The number of connectors on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com