Descaling wax-removing device for oil field equipment

A technology for oil field equipment and shells, which is applied to the field of descaling and wax removal devices for oil field equipment, can solve the problems of wasting manpower and material resources, complicated procedures, environmental pollution, etc., and achieves the effect of protecting the environment, avoiding environmental pollution, and having a good removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

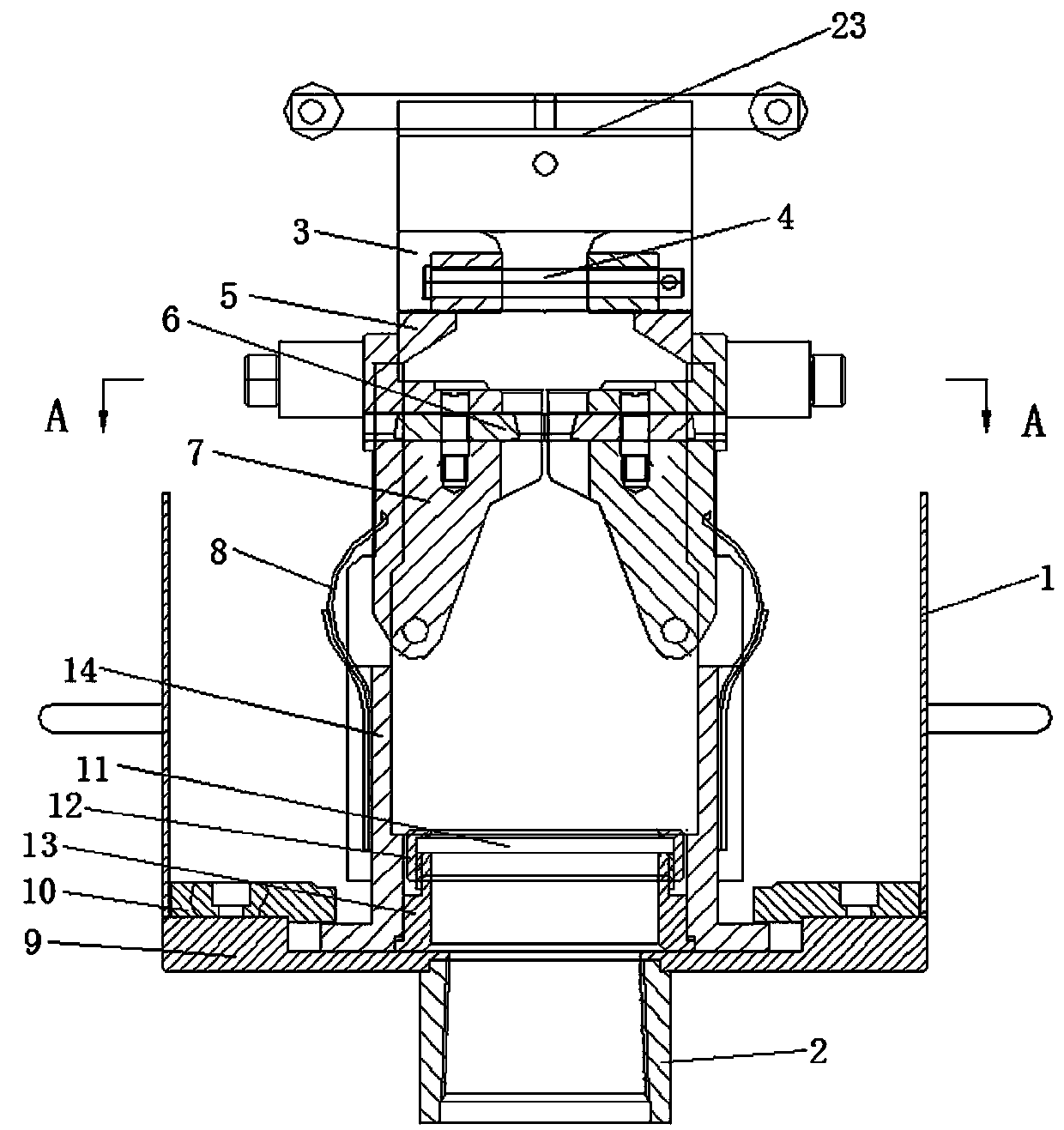

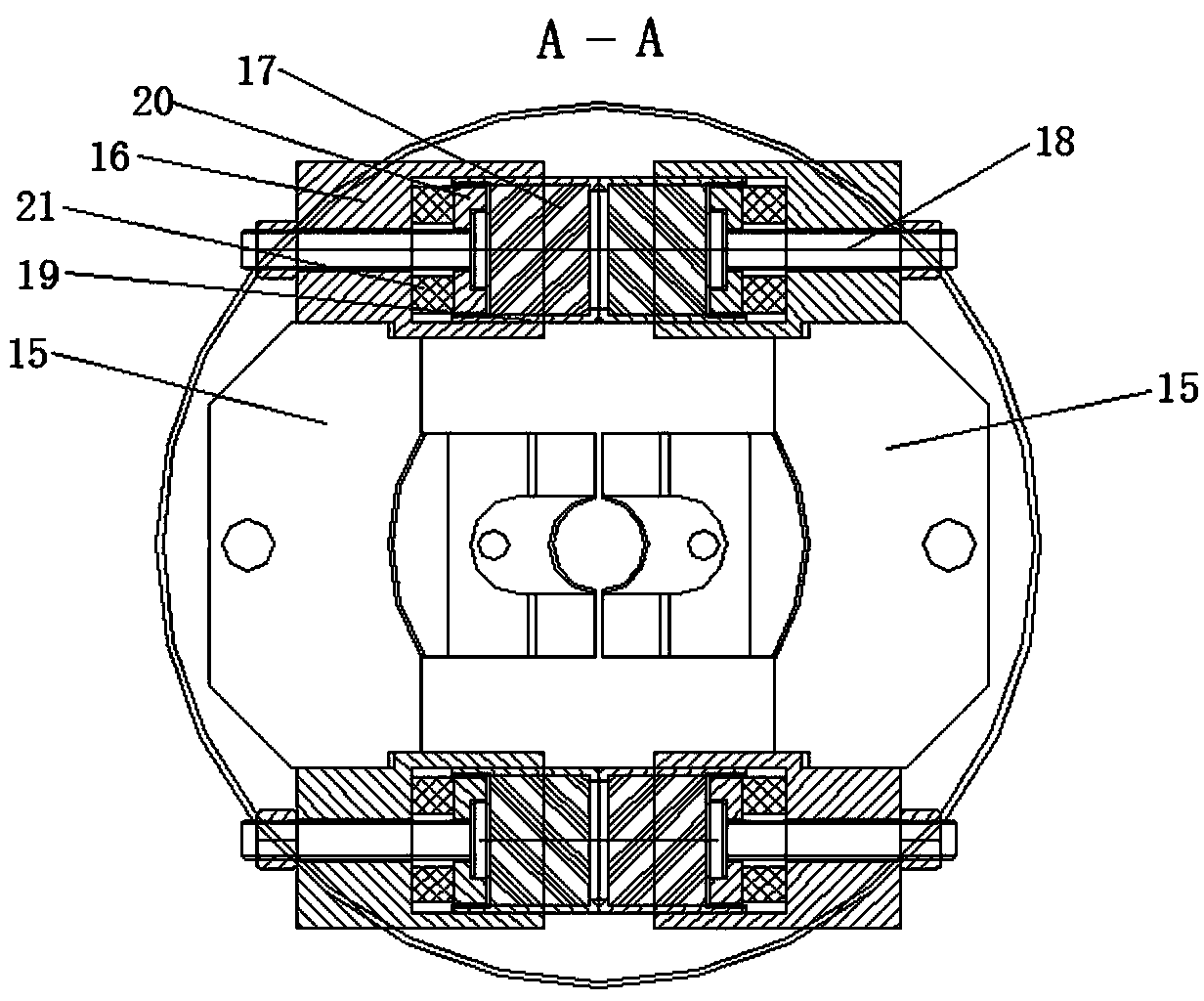

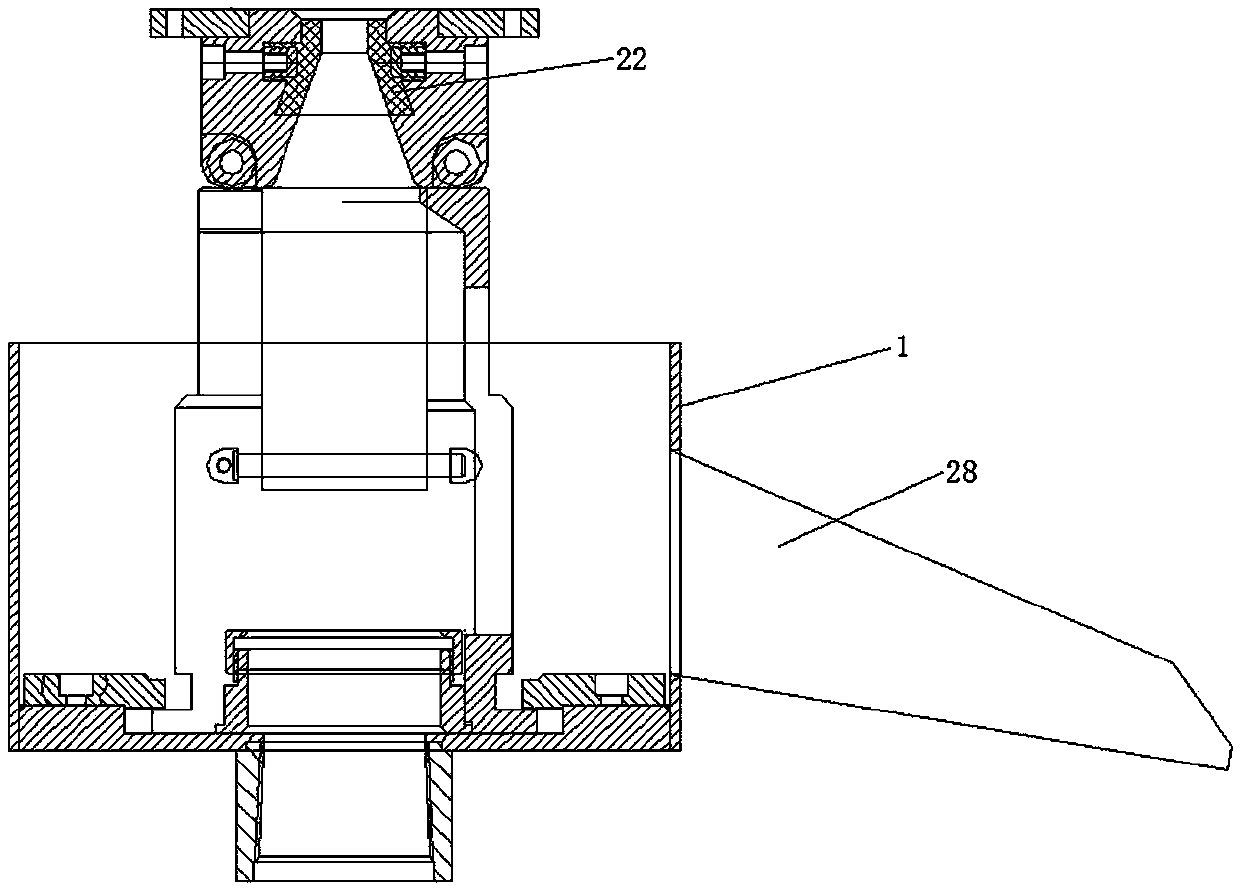

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, the descaling and wax removal device for oil field equipment includes a casing 1, a blade assembly and a rubber core assembly arranged in the casing 1, and a collar 2 arranged at the bottom of the casing 1, and the rubber core The assembly is arranged above the blade assembly, and the blade assembly includes a hinge 3, a hinge shaft 4, a floating body 5, a blade 6, a scraper support 7, a leaf spring 8, and a magnetic steel assembly that controls the movement of the blade 6. The casing 1 is provided with a lower flange 9 and an upper flange 10 in sequence, and the rubber plate 11 is arranged above the middle part of the upper flange 10. The rubber plate 11 is provided with a rubber plate cover 12 and is formed by a rubber plate seat. Supported by 13, a blade support 14 is provided between the outer side of the rubber plate se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com