Intermediate rolling mill area of the cast-rolling complex

A rolling compound, intermediate rolling mill technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problem of reducing equipment operation reliability, reducing investment and operating costs of casting and rolling compound equipment. and other problems, to achieve the effect of reducing the length of the structure, reducing the operating cost and improving the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

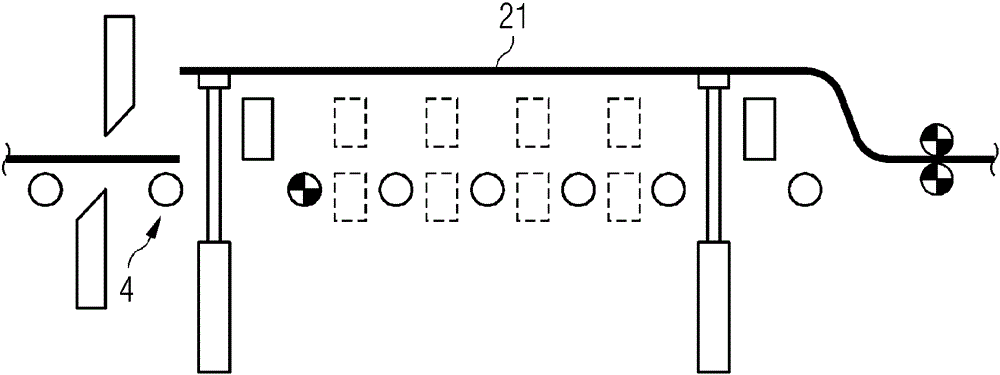

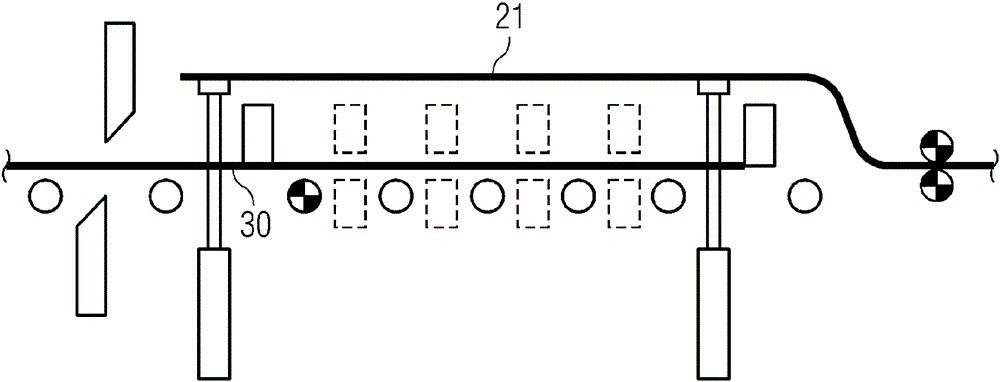

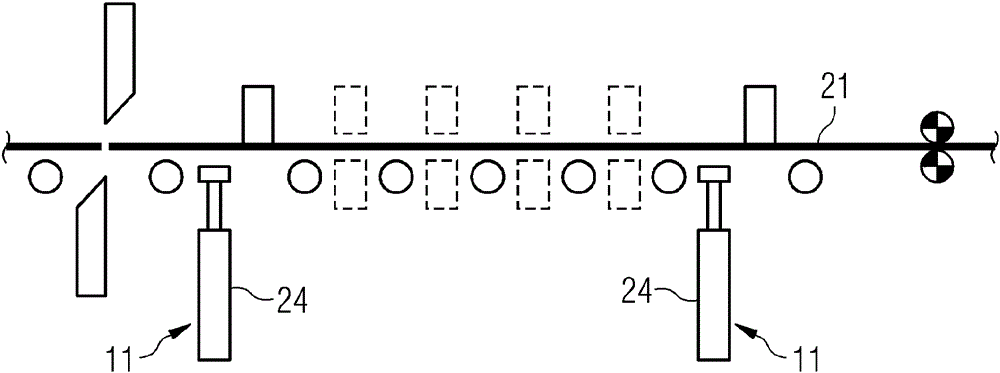

[0077] FIG. 1 shows a combined casting and rolling plant 1 known from WO 2009 / 121678 A1. In continuous operation, the continuous casting machine 2 continuously produces a precast material 3 in the form of thin-slab strands, which is conveyed via a roller table 4 to a roughing mill 5 . After rough rolling in the roughing mill 5, the roughed strip 30 is uncut, i.e. as a continuously cast slab, before it is hot-rolled into the finished strip 40 in a single-stand or multi-stand finishing mill 14 Through the intermediate mill zone Z comprising the induction furnace 12 and the descaling plant 13 . The finished strip 40 is then cooled in the cooling section 15 , cut to a defined product length or a defined product weight by a shear 16 and then coiled in a storage device 17 configured as a coiling device. The roller table 4 connects all equipment components between the horizontal continuous casting slab guide roller of the continuous casting machine 2 and the storage device 17; the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com