Car front seat beam B fitting clamp

A front seat and fixture technology, applied to vehicle parts, manufacturing tools, auxiliary devices, etc., can solve the problems of insufficient manual clamping reliability, large volume, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

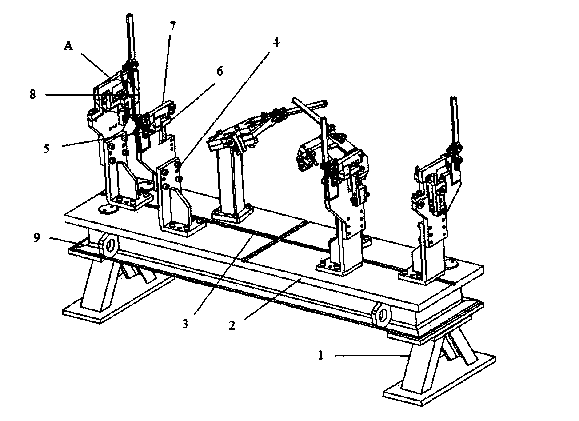

[0013] The specific embodiment of the present invention is as figure 1 and figure 2 As shown, the automobile front seat beam B assembly fixture includes a tripod 1 and a platform 2, and the upper surface of the platform 2 is provided with two cross reference grooves 3 perpendicular to each other; 3, five support columns 4 are installed in the longitudinal direction, and the support column 4 is provided with a clamping part 5, and the clamping part 5 is provided with an upper jaw body 7 and a lower jaw body 6 corresponding to the upper jaw body 7, through the upper jaw The relative movement of the body 7 and the lower jaw body 6 constitutes the opening and closing state of the clamp. The upper and lower jaws can be controlled by manually operating the handle 8 on the clamping part 5, thereby controlling the opening and closing state of the clamp.

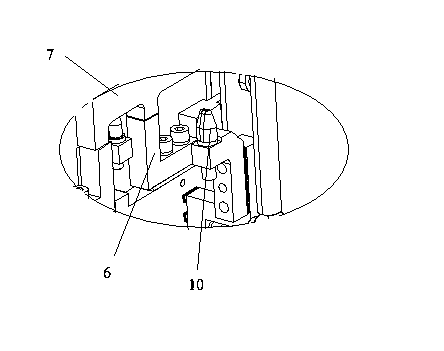

[0014] exist figure 1 Among them, a positioning pin 10 is provided near one side of the lower jaw body 6, figure 2 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com