Metal pipe cement mortar lining machine

A cement mortar lining and metal pipe technology, applied in the field of metal pipe manufacturing, can solve the problems of poor lining quality, low degree of automation, and poor adaptability of thin-walled metal pipes, so as to improve quality, improve automation, and prevent scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

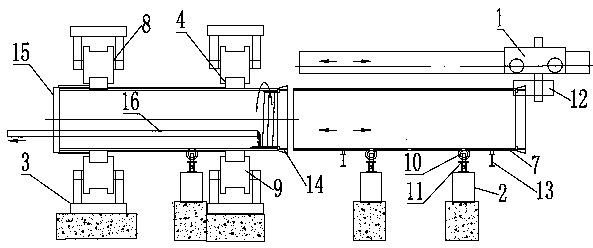

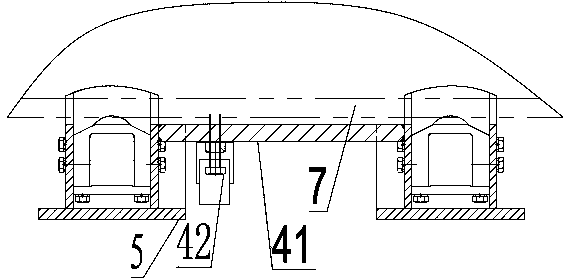

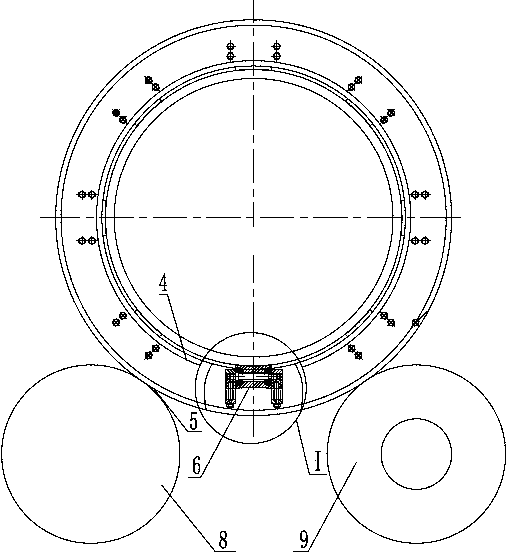

[0031] Such as Figure 1-6 As shown, a metal pipe cement mortar lining machine includes a metal pipe axial installation device 1, a metal pipe lifting device 2, a rotating support wheel group 3, an auxiliary lining 4, a PLC control cabinet 17 and a cement distribution boom 16. The lining machine can automatically install and insert the metal pipe into the auxiliary liner 4 in the axial direction. The auxiliary liner 4 includes a liner 41 , a clamping part 42 , a ring body 5 and a support wheel assembly 6 . The support wheel assembly 6 includes a support roller 61 , a rotating shaft 62 , a support frame 63 , an elastic member 64 , a bearing 65 and a fastener 66 .

[0032] During and after the installation of the metal pipe 7 to the auxiliary liner 4, the support roller 61 of the support wheel assembly 6 exerts appropriate pressure on it to complete the radial positioning and ellipse calibration of the metal pipe, and the welding on the liner 41 After the metal pipe 7 is posit...

Embodiment 2

[0039] Such as Figure 1-6 As shown, in this embodiment, a metal pipe cement mortar lining machine includes a metal pipe axial installation device 1, a metal pipe lifting device 2, a rotating support wheel group 3, an auxiliary lining ring 4, and a PLC control cabinet? And cement placing boom 16. The lining machine realizes the automatic axial installation of the metal pipe and inserts it into the auxiliary lining 4. The auxiliary lining 4 completes the positioning, clamping, ellipse correction of the metal pipe and the improvement of the rigidity of the metal pipe. After the lining is completed, the metal pipe axis The removal of the metal pipe to the installation device 1 is automatically completed. Compared with Embodiment 1, the difference between the auxiliary bushing 4 and the auxiliary bushing 4 is that the cylinder 41 used to connect two sets of auxiliary bushings 4 is reduced, so that the auxiliary bushing 4 only includes the ring body 5 and the supporting wheel asse...

Embodiment 3

[0042] Such as Figure 1-6 As shown, in this embodiment, a metal pipe cement mortar lining machine includes a metal pipe axial installation device 1, a metal pipe lifting device 2, a rotating support wheel group 3, an auxiliary lining 4, and a PLC control cabinet? And cement placing boom 16. The lining machine realizes the automatic installation and insertion of the metal pipe axially into the auxiliary liner 4, and the auxiliary liner 4 completes the positioning, clamping, ellipse correction of the metal pipe and the improvement of the rigidity of the metal pipe. After the lining is completed, the metal pipe axis The removal of the metal pipe to the installation device 1 is automatically completed. Compared with embodiment 1, the rotating supporting roller group 3 reduces the passive supporting roller 8 that cooperates with the rotation of the metal pipe, and only keeps the active supporting roller 9, and the auxiliary lining 4 rotates under the drive of the driving supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com