Preparation method of nano-scale silicon dioxide

A silica and nano-scale technology, applied in the chemical industry, can solve the problems of expensive raw materials, less surface hydroxyl groups, and small dispersed particle size, and achieve the effects of low cost, wide sources, and convenient material acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

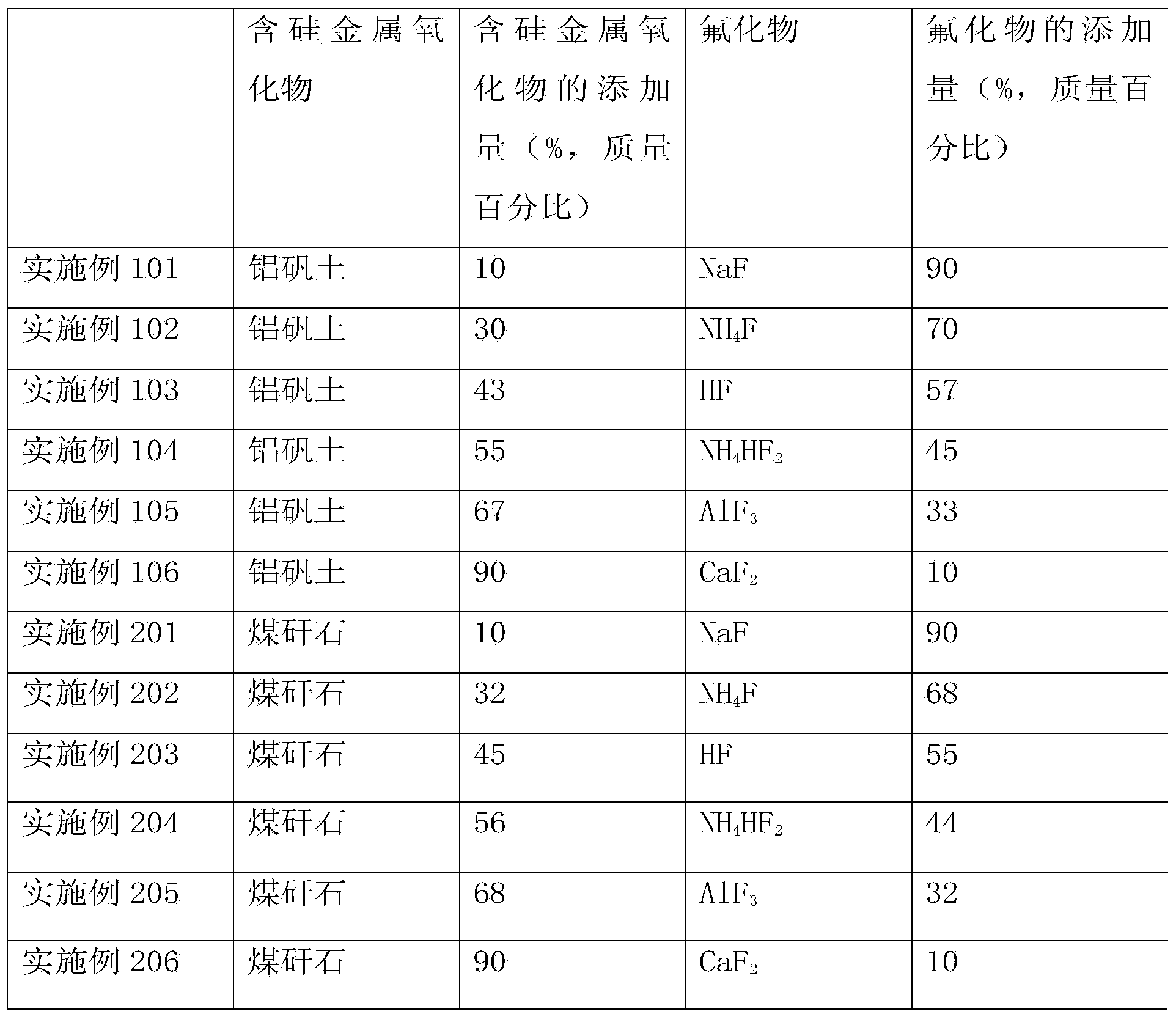

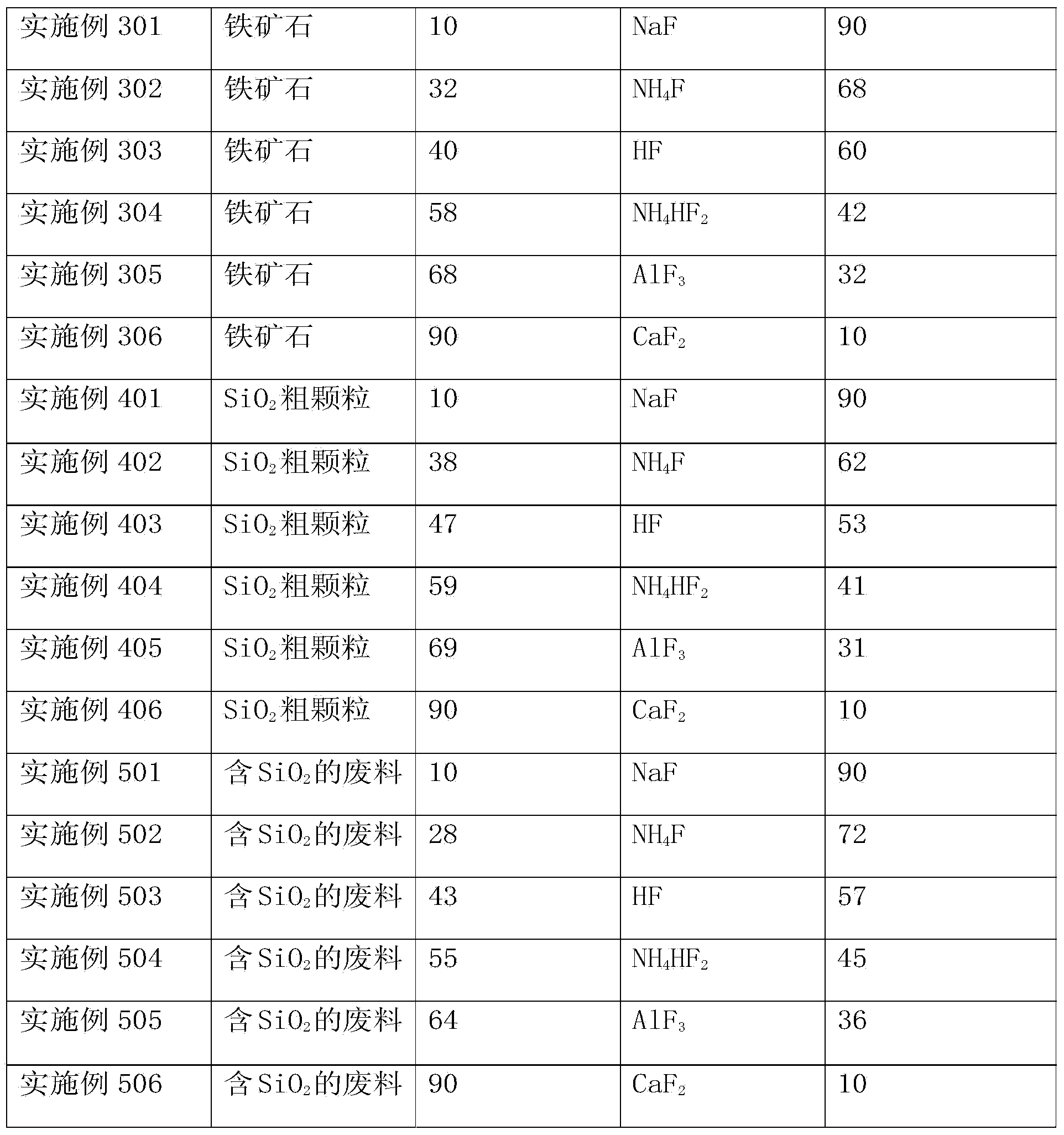

[0024] The embodiment of the present invention provides a preparation method of nano-scale silicon dioxide, comprising:

[0025] After mixing the silicon-containing substance and the fluoride, the fluorination reaction is carried out to obtain gas-phase silicon tetrafluoride;

[0026] High-temperature hydrolysis of the silicon tetrafluoride to obtain nano-scale silicon dioxide;

[0027] performing quenching crystallization on the silicon dioxide to obtain the granular silicon dioxide;

[0028] Wherein, the silicon-containing material includes any one or more of the following: minerals containing silicon metal oxides or waste materials containing silicon dioxide.

[0029] The reactant that adopts in the present invention is the silicon-containing substance of the mineral of silicon-containing metal oxide or the waste material containing silicon dioxide, and this raw material abounds in everywhere, and source is wide, and material is convenient, and cost is lower, and because s...

Embodiment 1

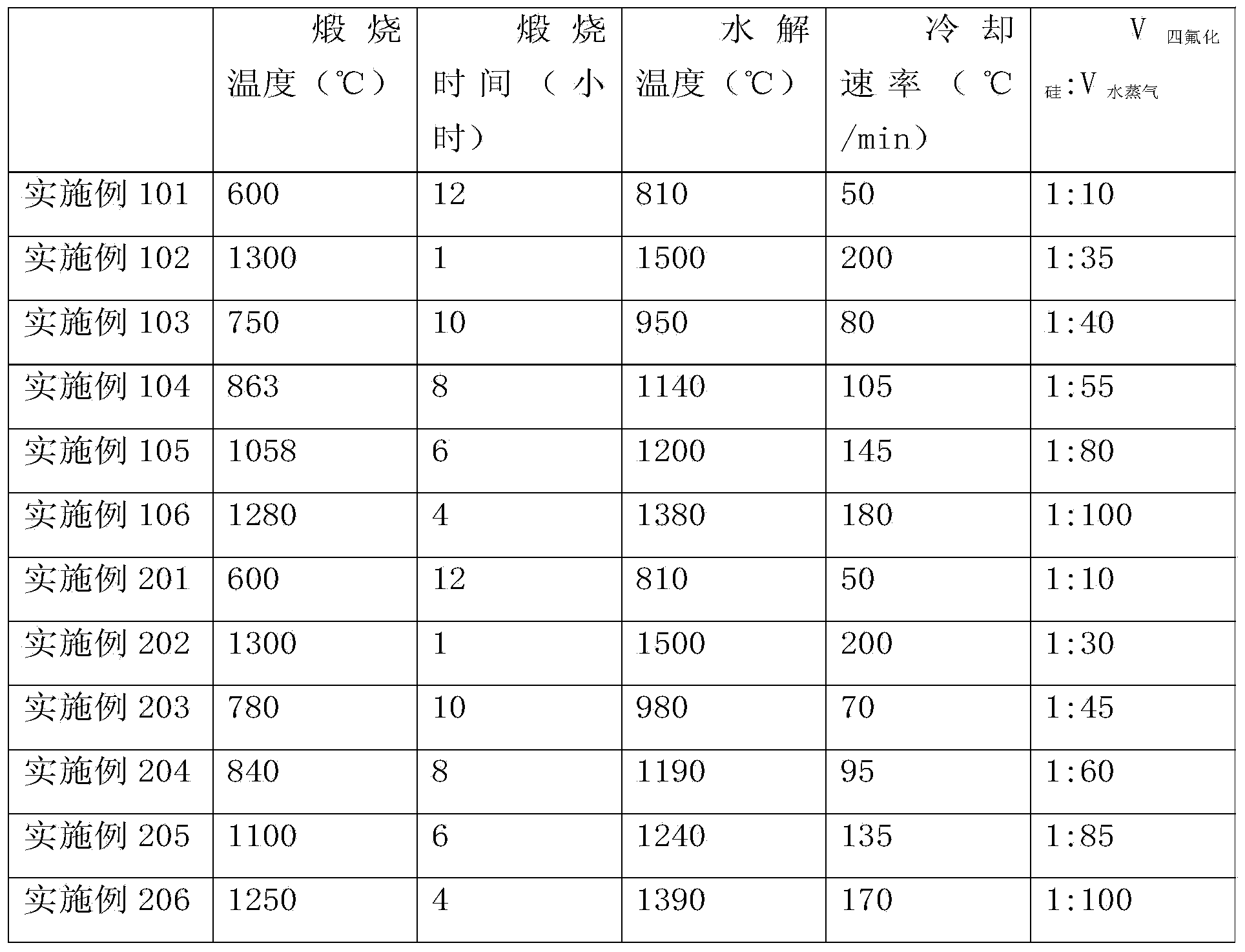

[0068] Embodiment 1: with coarse particle SiO 2 and NH 4 F as raw material to prepare nanoscale SiO 2 powder

[0069] Coarse SiO 2 and NH 4 F mixed evenly, coarse particle SiO 2 with NH 4 The particle size of F is less than 3mm, and the NH in the resulting mixture 4 The mass percentage of F is 10%. Calcinate the mixture at a temperature of 600-800°C for 5 hours to generate NH 3 、H 2 O and SiF 4 , SiF 4 escaped from the solid. SiF that will escape 4 Introduce into another reactor, and feed water vapor, the volume ratio of silicon tetrafluoride and water vapor is 1:10, after hydrolysis at 810-1000°C, dry and dehydrate with concentrated sulfuric acid to remove NH 3 , generating SiO 2 and HF gas. Quenching of high temperature mixed gas to obtain SiO 2 Granules, the cooling rate is 100°C / min. Particles undergo post-treatment processes such as aggregation, separation, and deacidification to obtain SiO 2 Powder, particle size: about 50-80 nanometers. The reaction e...

Embodiment 2

[0072] Embodiment 2: with bauxite and AlF 3 Preparation of fine particle size SiO as raw material 2 powder

[0073] Bauxite ((Al 2 o 3 ) m (TiO 2 ) n SiO 2 ) with AlF 3 Mix well, bauxite and AlF 3 The particle size is below 5mm, and the AlF in the resulting mixture 3 The mass percentage is 40%. Calcinate the mixture at a temperature of 1100-1300°C for 4 hours to generate Al 2 o 3 and SiF 4 , SiF 4 escaped from the solid. SiF that will escape 4 Introduce into another reactor and feed water vapor, the volume ratio of silicon tetrafluoride and water vapor is 1:40, and SiO will be generated after hydrolysis at 1000-1200 °C 2 and HF gas. Quenching of high temperature mixed gas to obtain SiO 2 For pellets, the cooling rate is 50-200°C / min. Particles undergo post-treatment processes such as aggregation, separation, and deacidification to obtain SiO 2 Powder, particle size: about 5-47 nanometers. The reaction equation is as follows:

[0074] 3SiO 2 +4AlF 3 ·3H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com