Fermented grain quick cooling machine

A rapid cooling and fermented grain technology, applied in the preparation of alcoholic beverages, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of large area, incomplete cooling, and high energy consumption of coolers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

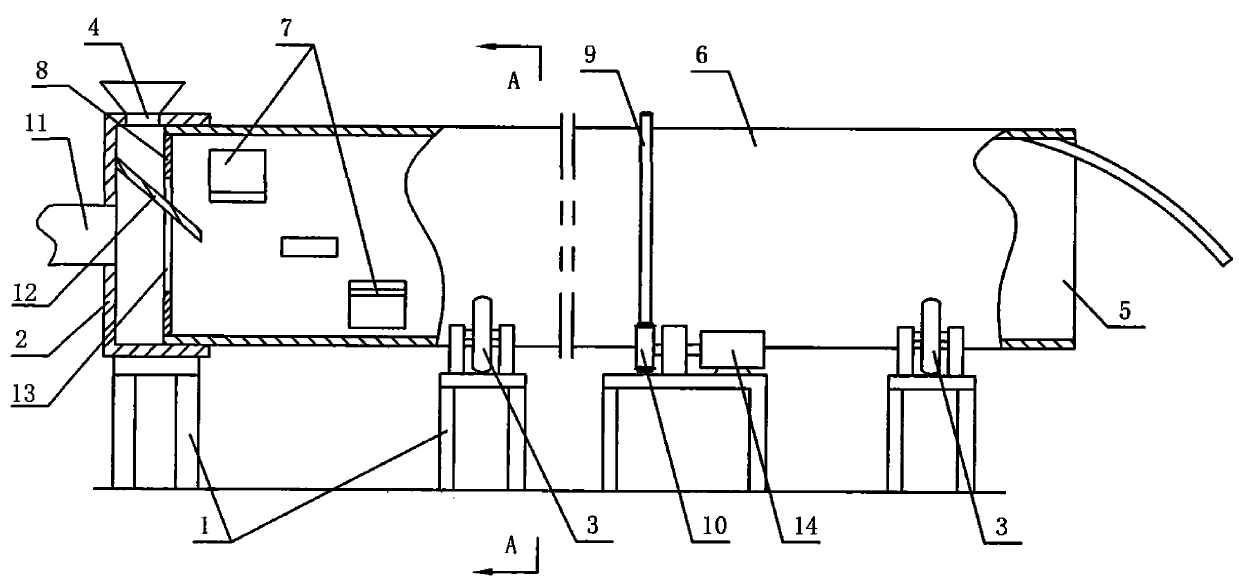

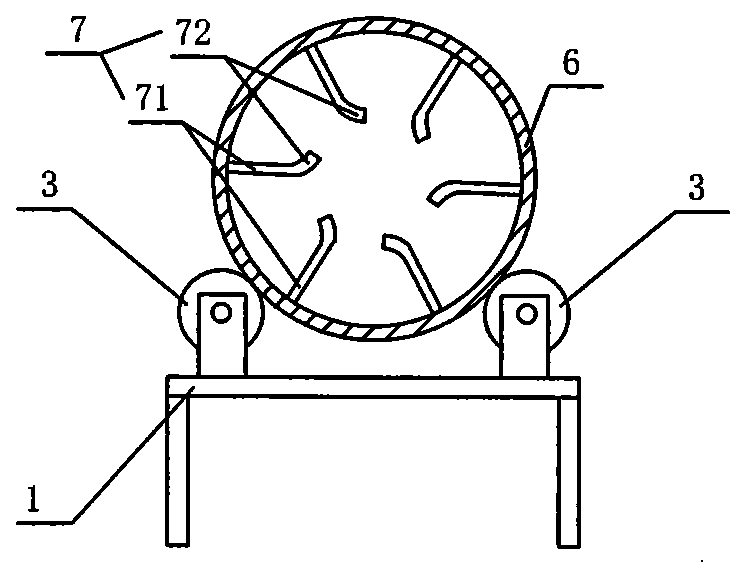

[0011] The present invention distinguishes front and rear according to the direction of the fermented grains, with the feeding direction as the front and the discharging direction as the rear, such as figure 1 and figure 2 The wine grains coolant shown includes a frame 1, the front end of the frame 1 is fixedly equipped with a feeding cylinder 2, the front end of the feeding cylinder 2 is closed, and the rear end is open, and the top of the circumferential surface of the feeding cylinder 2 is provided with a feeding cylinder 2. Port 4, the outer end wall (i.e. the front end wall) is connected with an induced air pipe 11, which can be equipped with an induced draft fan, and the frame 1 is also rotatably connected with a front end connected with the feeding cylinder 2 and inclined from front to back The cooling cylinder 6 arranged downwards, the front port of the cooling cylinder 6 is fixedly connected with the retaining ring plate 8, the middle part of the retaining ring plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com