A high-strength magnesium alloy extruded seamless pipe and its preparation process

A technology of seamless pipe and preparation process, applied in the field of metal material processing technology and metallurgy, can solve the problems of cracking or fracture, low strength fatigue strength, poor tissue compactness, etc., and achieves high utilization rate, good service performance, tensile strength and The effect of high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

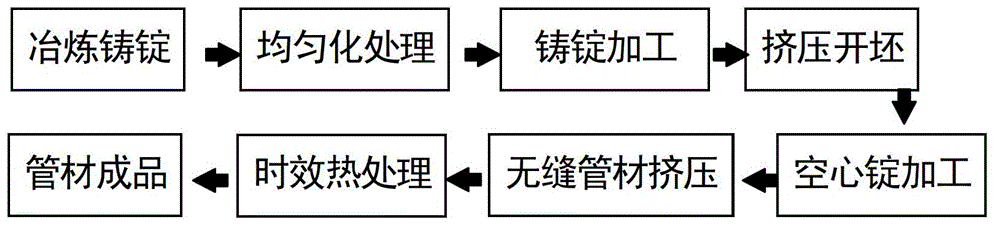

Method used

Image

Examples

Embodiment 1

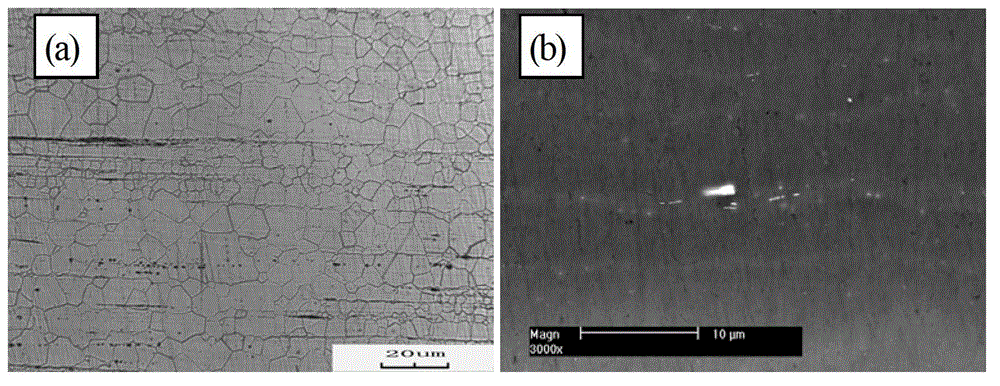

[0041] A cylindrical ingot with a diameter of 270 mm and a height of 380 mm was obtained by metal mold gravity casting. After chemical analysis, its chemical composition is: Mg-9.52Gd-2.88Y-0.31Zr. The alloy ingot was homogenized at 500°C for 16 hours; after the treatment, the ingot was peeled off to obtain an ingot for extrusion. The ingot used for extrusion was kept at 400° C. for 3 hours, put into the extrusion cylinder and carried out a billet extrusion, and obtained a billet with a diameter of 150 mm. The blanked bar stock is further machined into a hollow ingot with a diameter of 145 mm and a hole with a diameter of 45 mm in the center. The hollow ingot was kept at 460°C for 3 hours, extruded by a double-action horizontal extruder with a perforating needle with a diameter of 46 mm, and the diameter of the die hole was 60 mm to obtain a seamless pipe with an outer diameter of 60 mm and an inner diameter of 46 mm. The thickness of the pipe is 7mm and the length is about ...

Embodiment 2

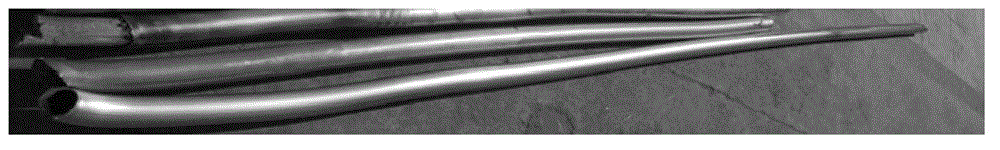

[0043] A cylindrical ingot with a diameter of 270 mm and a height of 400 mm was obtained by metal mold gravity casting. After testing, the chemical composition of the alloy is: Mg-9.25Gd-2.88Y-0.46Zn-0.39Zr. Alloy ingots were homogenized at 500°C for 16 hours; peeled after treatment. The alloy ingot was kept at a temperature of 400°C for 3 hours, put into the extrusion barrel for one billet extrusion, and obtained a primary billet bar with a diameter of 150 mm. The blanked bar stock is further machined into a hollow ingot with a diameter of 145 mm and a hole with a diameter of 45 mm in the center. The hollow ingot was kept at 480°C for 3 hours, extruded by a double-action horizontal extruder with a perforating needle with a diameter of 46mm, and the diameter of the die hole was 60mm to obtain a seamless pipe with an outer diameter of 60mm and an inner diameter of 46mm. The thickness of the pipe is 7mm and the length is about 4000mm, such as Figure 5 . The seamless pipe ob...

Embodiment 3

[0045] A cylindrical ingot with a diameter of 270 mm and a height of 420 mm was obtained by metal mold gravity casting. After testing, the chemical composition of the alloy is: Mg-9.04Gd-1.91Y-0.97Zn-0.32Zr. The alloy ingot was homogenized at 520°C for 10 hours; after the treatment, the ingot was peeled off to obtain an alloy ingot. The alloy billet was kept at 420° C. for 5 hours, put into the extrusion cylinder for one-time billet extrusion, and obtained a first-time billet billet with a diameter of 125 mm. The primary billet billet is further machined into a hollow billet for extrusion of a seamless pipe with a diameter of 120 mm and a hole in the center with a diameter of 50 mm. After the hollow ingot is kept at 440°C for 3 hours, it is extruded by a double-acting horizontal extruder with a perforating needle with a diameter of 46mm. The diameter of the die hole is 68mm to obtain a seamless pipe with an outer diameter of 68mm and an inner diameter of 46mm, the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com