An integrated device for cleaning and repairing cracks on cement concrete pavement

A cement concrete and concrete pavement technology, which is applied in cement concrete pavement maintenance and repair equipment and pavement machinery, can solve problems such as low work efficiency, waste of manpower, improper connection, etc., and achieve high practical value, reasonable design, and orderly construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

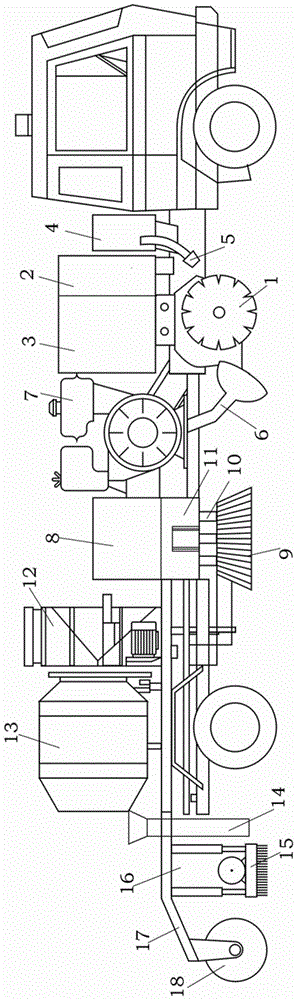

[0015] Example: such as figure 1 An integrated device for cleaning and repairing cracks on cement concrete pavement includes a body, and the front and rear of the body are arranged in sequence: planing and milling parts, returning parts, scrubbing tools, stirring packing parts and vibrating and compacting parts for processing the packing parts.

[0016] The planing and milling components include an engine 2, the engine 2 is connected with the planing and milling machine 1 located on the chassis frame through a gearbox 3, and a nozzle 5 connected with a water tank 4 is arranged above the front side of the planing and milling machine 1.

[0017] The returning part includes a prime mover 7 , a rigid debris suction pipe 6 provided by the prime mover 7 , and the rigid debris suction pipe 6 is connected with a debris collection box 8 .

[0018] The scrubbing appliance includes a motor 11 and a rotating brush 9 powered by the motor 11 , and the motor 11 and the rotating brush 9 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com