Passive/active-selectable cantilever type dynamic vibration absorber

A dynamic vibration absorber and cantilever beam type technology, which is applied in the field of vibration absorbers, can solve the problems that the natural frequency cannot be adjusted from time to time, and the vibration absorption effect is poor, and achieves the effect of simple structure, good vibration absorption requirements and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

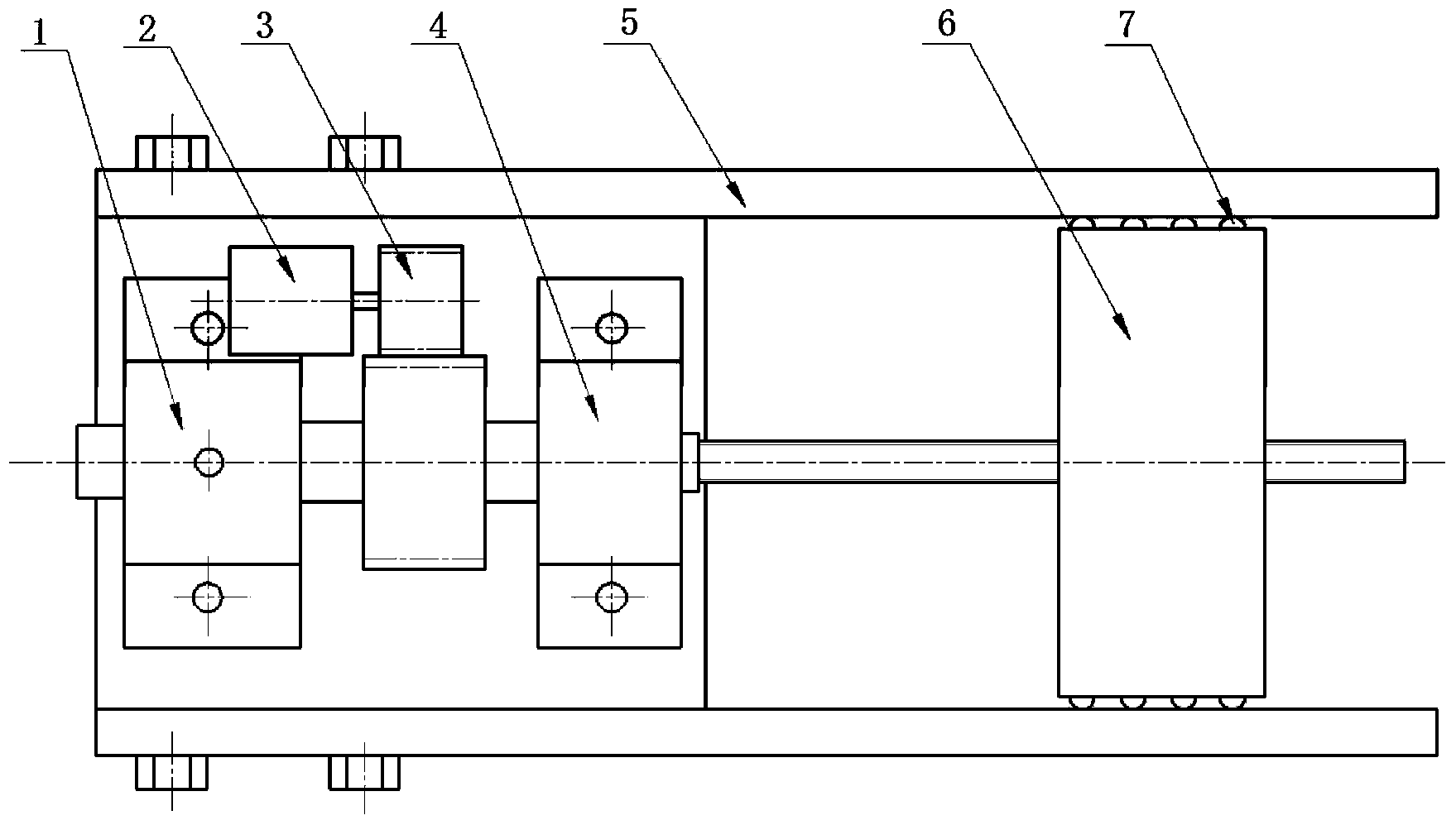

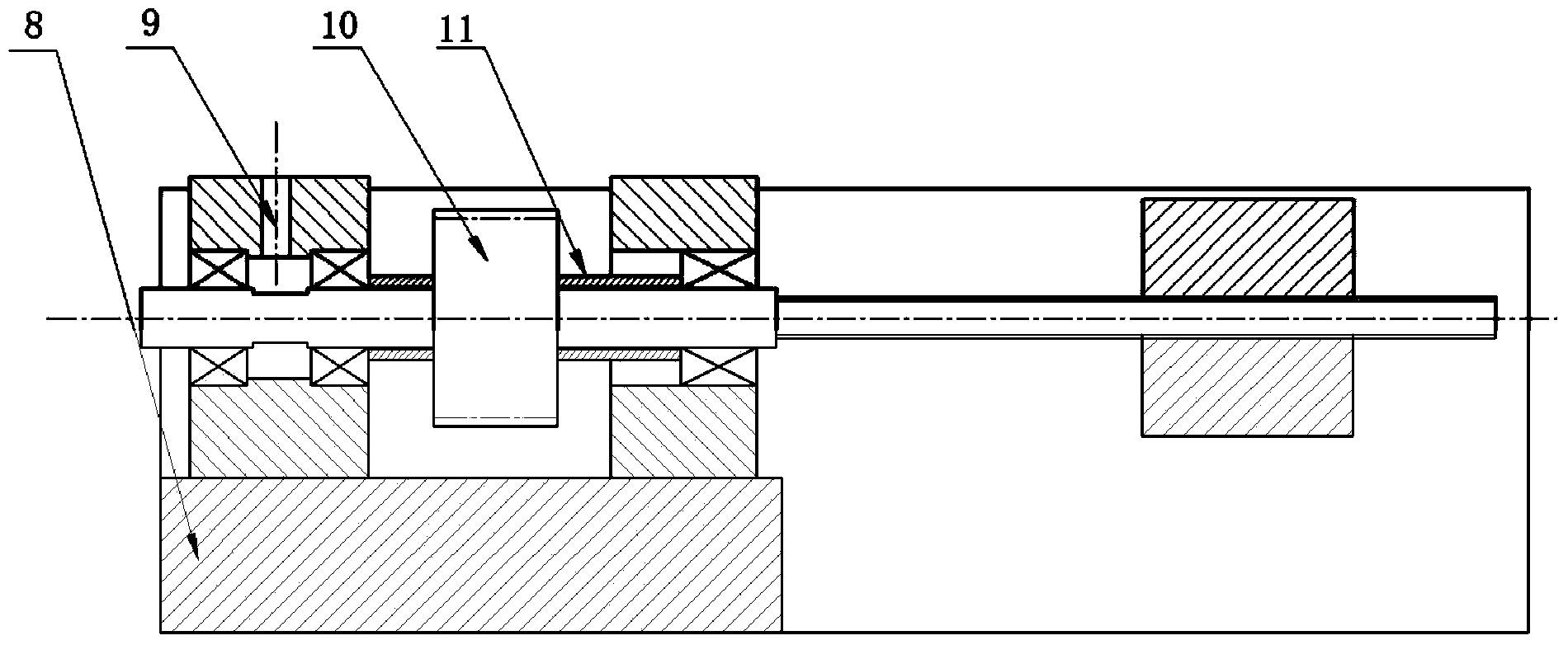

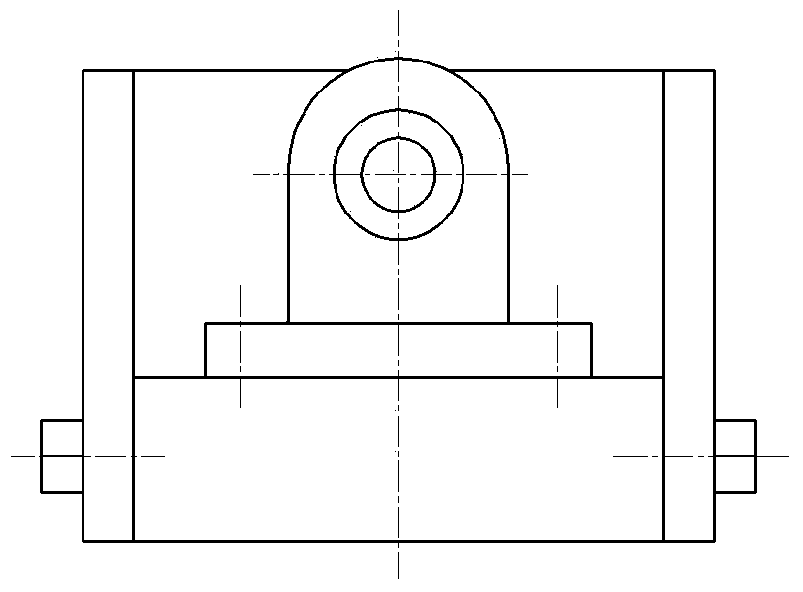

[0016] The present invention will be described in more detail below in conjunction with the accompanying drawings:

[0017] combine Figures 1 to 4 , The structure of the present invention mainly includes the front bearing base 4, the rear bearing base 1, the stepping motor 2, the stepping motor base 14, the driving gear 3, the baffle 5, the mass block 6, the ball 7, the gear shaft 10, the vibration absorption device base 8 , control device 13 , sensor 12 . One end of the gear shaft 10 is designed with a lead screw, and the inner hole of the mass block 6 is tapped with a thread. Together they form a mechanical cantilever beam vibration absorber. The stepping motor 2, the driving gear 3, the control device 13, the sensor 12, etc. constitute the frequency adjustment part. The driving gear 3 and the gears on the gear shaft 10 form a gear pair, and the driving gear 3 is driven by the stepping motor 2 . When the gear shaft 10 rotates, the mass block 6 moves in the horizontal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com