Functional steel pipe

A functional, steel pipe technology, applied in the direction of rigid pipes, pipes, pipes/pipe joints/fittings, etc., can solve the problems of low strength and high cost, and achieve the effect of improving overall performance and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

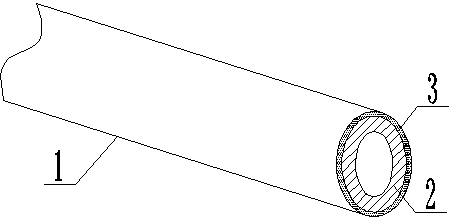

[0010] Such as figure 1 It is a structural schematic diagram of the present invention, a functional steel pipe, including a pipe body 1, and the pipe body 1 is composed of a stainless steel layer 2 and a color masterbatch resin layer 3. The stainless steel layer 2 is located in the inner layer of the pipe body 1, and the color masterbatch resin layer 3 is located in the outer layer of the pipe body 1.

[0011] The tube body 1 is designed as a combined structure of two materials. The stainless steel layer 2 is located in the inner layer of the tube body 1, and the color masterbatch resin layer 3 is located in the outer layer of the tube body 1. The two materials complement each other, which not only retains the excellent characteristics of the stainless steel layer 2 , and give full play to the advantages of the masterbatch resin layer 3 in anti-ultraviolet, anti-aging, rich colors and easy identification, which not only improves the overall performance of the pipe body 1, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com