A self-powered fuel heater

A fan heater, self-powered technology, applied in air heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of fast cold wind speed, external power supply, inability to adjust the fuel injection volume, etc., to improve power generation and Efficiency, reduced size and weight, self-powered operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

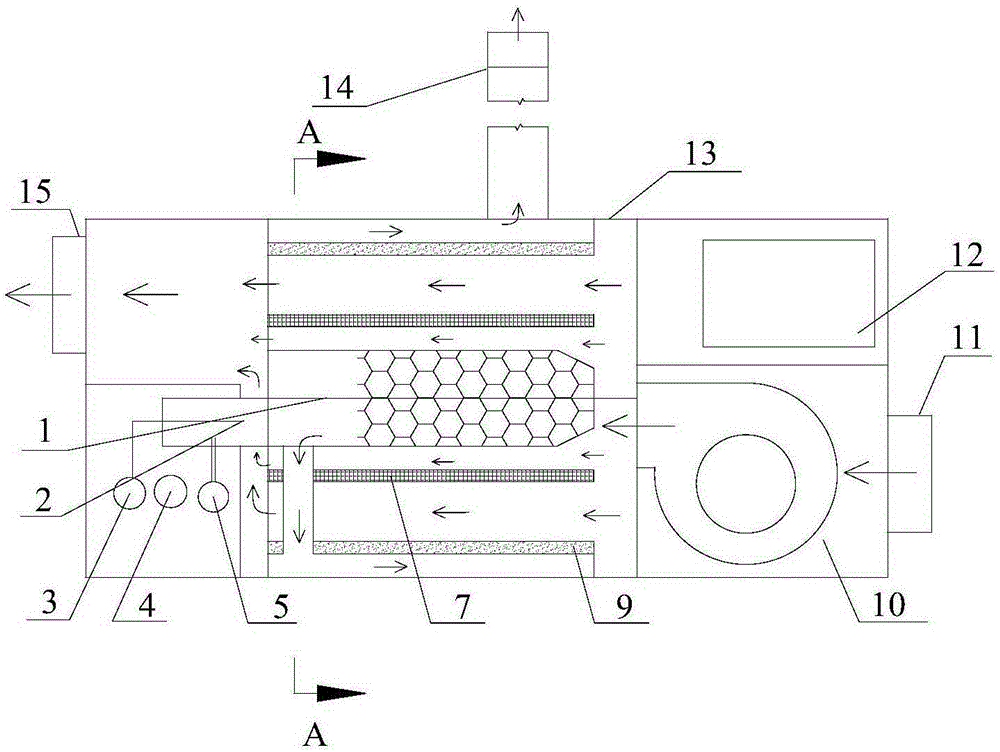

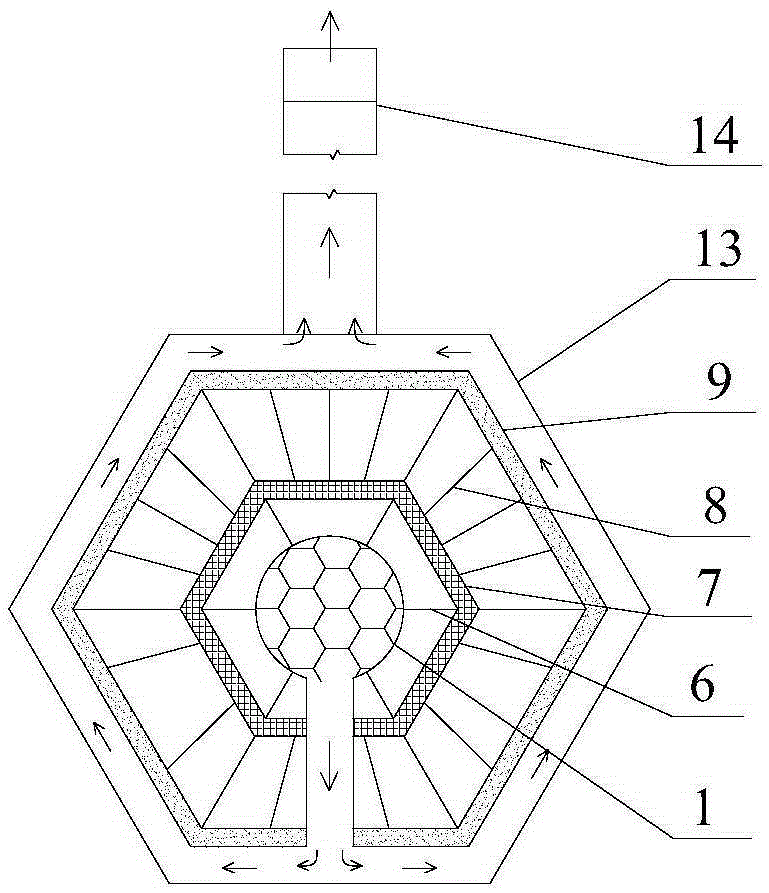

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] see Figure 1-2 , the present invention comprises shell 13 that has chimney 14, and the control system that is used to control temperature and air blower is arranged on shell 13, and cylindrical combustion chamber 1 with flue gas outlet is arranged in shell 13, and one end of combustion chamber 1 is provided with burner 2. The other end is provided with a blower 10, and the outer side of the combustion chamber 1 is provided with a first heat conduction layer and a second heat conduction layer in sequence. The high temperature thermoelectric module 7 is fixed on the first heat conduction layer, and the low temperature thermoelectric module is fixed on the second heat conduction layer. 9. The first heat conduction layer and the second heat conduction layer are regular prismatic structures with several heat conduction plates opening at both ends of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com